A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

2 7

in this deposit layer actually increases

resistance to further corrosion, hinder-

ing its own progress. However, it can-

not be completely stopped due to the

porosity of Mg(OH)

2

and the growth

continues deeper into the metals.

In order to determine electric

current distribution and analyze the

chemical response, the non-constant

growth and influencing material prop-

erties must be accounted for. Using

the

Chemical Reaction Engineering

and Batteries & Fuel Cells

modules in

the simulation software, the rivet and

sheet metal are treated like a set of

electrodes. This allows assessment of

the anode/cathode area ratio, elec-

trolyte exposure duration, and chang-

es in electric current due to Mg(OH)

2

buildup, which contributes to the mag-

nesium degradation.

Because porosity directly affects

barrier properties, the resulting sur-

face topology is influenced by the

downward degradation velocity and

the opposing growth of the deposit.

Basic galvanic current density compu-

tations were modified by these layer

growth aspects. This led to the study of

time-dependent variations in the elec-

trochemical response of the electrodes.

The model includes chemical

reaction rates, known electrochem-

ical properties of the metals, and a

time-dependent function with an expo-

sure period of 24 hours. Results report

the electric potential and current densi-

ty when the rivet joint is exposed to the

electrolyte, and reveal surface coverage

(proportion of sheets and rivet surfaces

covered by Mg(OH)

2

) at different times

after immersion. Current density varies

over distance from the center of the riv-

et, showing where corrosion will occur

most rapidly (Fig. 3).

DELAMINATION RISKS

In addition to galvanic corrosion

at the rivet-sheet interface, automotive

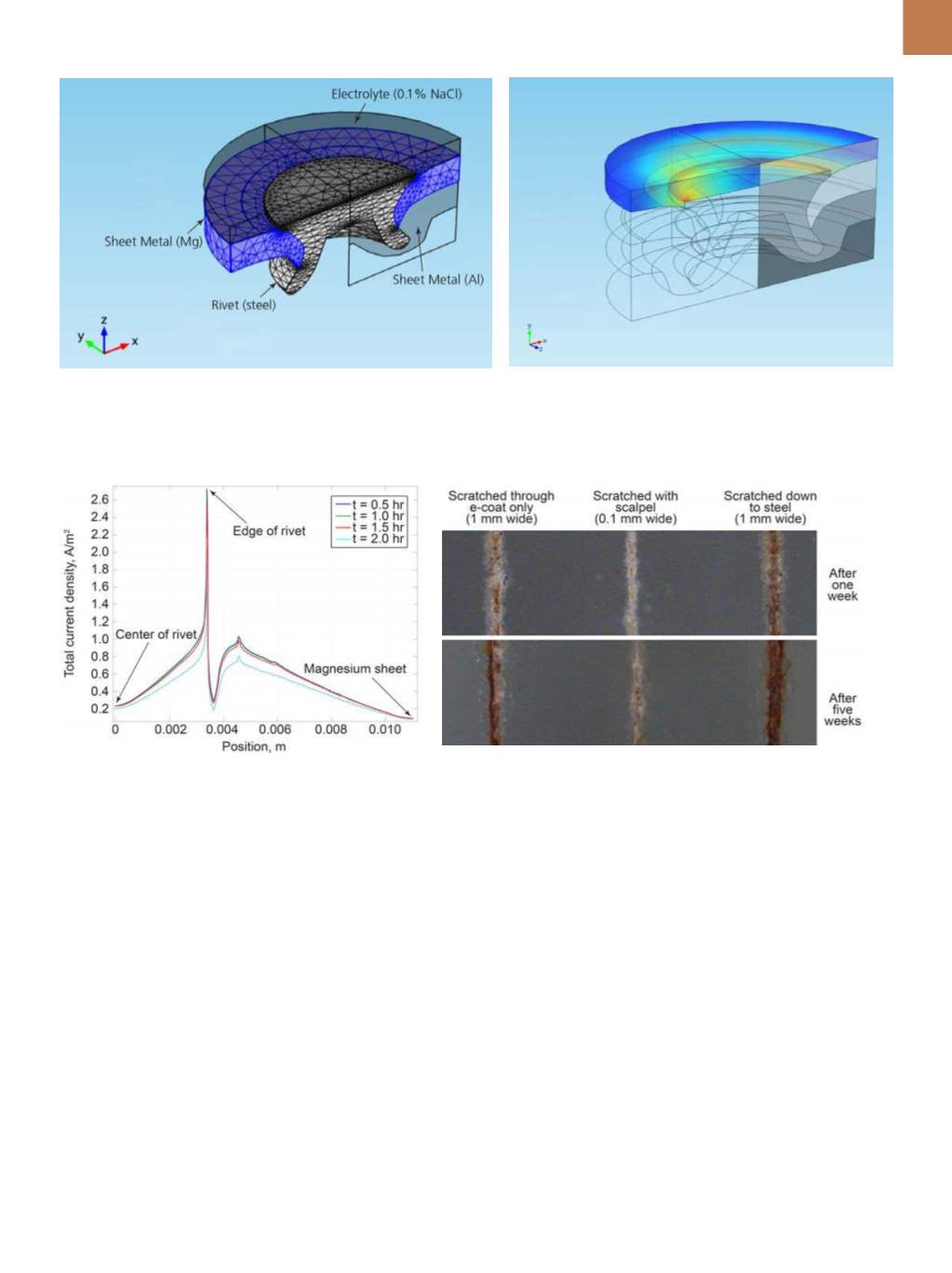

Fig. 2 —

Geometry depicting half of a punch rivet joint in COMSOL Multiphysics software (left). Simulation results show current density at the sur-

face of the rivet and sheet metal. The simulation mathematically models current flow at the rivet-sheet interface; the highest current density occurs

at the sharp edge (right).

Fig. 3 —

Simulation software plot showing localized current

density at different positions on the rivet joint’s surface.

Fig. 4 —

Corrosion test on a galvanized steel sheet showing visible corrosion

in the scratched layers (view from above). Several initial scratches of varying

depths and widths were created in order to analyze the influence of scratch size

on the delamination process. Results are shown after one week (top) and five

weeks (bottom).