A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 5

2 8

components are also at risk from expo-

sure to natural elements. Seemingly

superficial imperfections, such as a

scratch in the coating or paint on a

panel, allow moisture and environmen-

tal electrolytes access to electrically

conductive surfaces. In car paneling,

small impairments can create a galvan-

ic couple that causes delamination—

the debonding of coatings on metal

sheets—which significantly weakens

the corrosion protection.

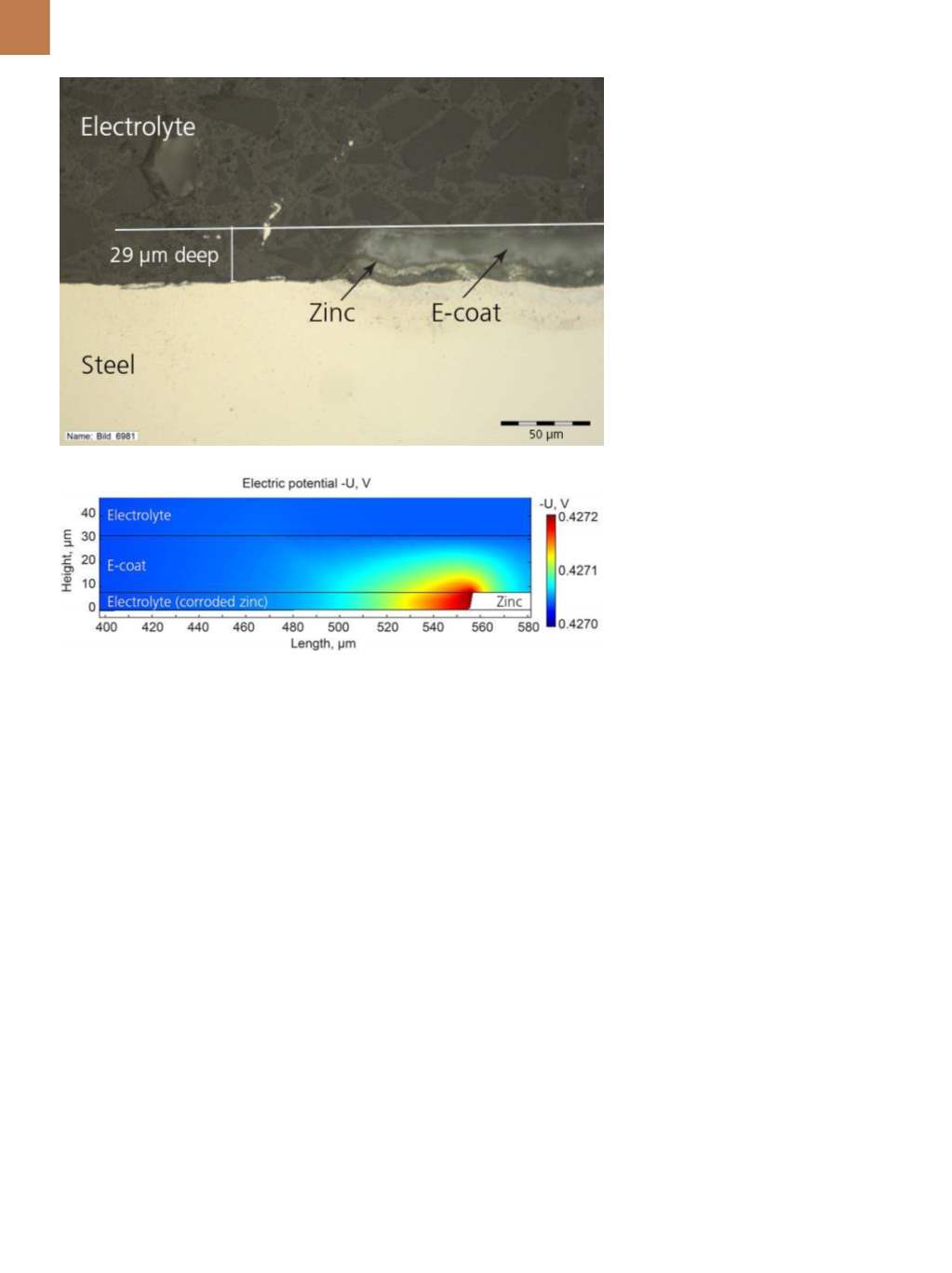

To analyze this additional risk,

Höche worked with Nils Bösch of

Daimler AG to study delamination on a

zinc-plated steel test sheet electrocoat-

ed with a layer of cathodic paint called

an

e-coat

(Fig. 4). If a scratch extends

down to the steel surface, a galvanic

couple occurs between the zinc and

steel causing the zinc to corrode. This

results in a crevice that grows continu-

ously between the e-coat and steel in a

horizontal direction, rather than verti-

cally through the layers. This behavior

is similar to crevice corrosion, which

digs between two surfaces and creates

fissures in the metal. Stress fractures at

the base of these cracks can eventual-

ly cause part failure, even though the

obvious damage and overall material

loss may appear small.

Höche and Bösch used paramet-

ric sweeps in the simulation software

to study the electric potential in the

electrolyte and e-coat for different

e-coat barrier properties. Their model

reports the corresponding horizontal

growth of the crevice as it consumes

the zinc (Fig. 5).

The quest to understand how the

size of these surface defects impacts

the rate of zinc consumption is ongo-

ing. So far, the model indicates that

the width of these defects has a great-

er influence than the depth—a smaller

cathode/anode ratio and more limited

diffusion is present in the narrower

scratches, which slows the corrosion

process compared to a wider impair-

ment. Existing results are being used

to further investigate coating flaws for

their negative influence on corrosion

protection.

LONGER-LASTING

STRUCTURAL SUPPORT

Although corrosion cannot be

avoided entirely, it can be minimized

through expert design and careful anal-

ysis. Höche and Bösch reduced the

sharp edges in the rivet joint and honed

the geometry to minimize the exposed

area while maintaining mechanical

stability. They also recommended an

e-coat for the sheet metal that, based

on the parametric study, exhibits the

lowest electric current and therefore,

the least decay in the paneling. Their

computer models offer valuable insight

into relevant electrochemical behavior,

providing engineers the tools to opti-

mize rivet joints to offer the best corro-

sion resistance.

Computer-aided analysis can

enhance recent progress regarding

lightweight, multi-material designs

and enable identification of possi-

ble corrosion problems early in the

development cycle. Despite corrosion

being an enemy to the automotive

rivet, control of magnesium corrosion

through knowledge-based processing

and careful geometric design is within

reach.

~AM&P

For more information:

Lexi Carver is

technical marketing engineer, COMSOL

Inc., 1 New England Executive Park, Bur-

lington, MA 01803, 781.273.3322,

lexi. carver@comsol.com,

www.comsol.com.Fig. 5 —

Close-up of a cross-section of the test sheet where a scratch destroyed part of the

e-coat and zinc layers (top). Simulation software results show the electric potential in the e-coat

and electrolyte. The white region shows remaining zinc after much of it was already consumed

(bottom).