A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

3 3

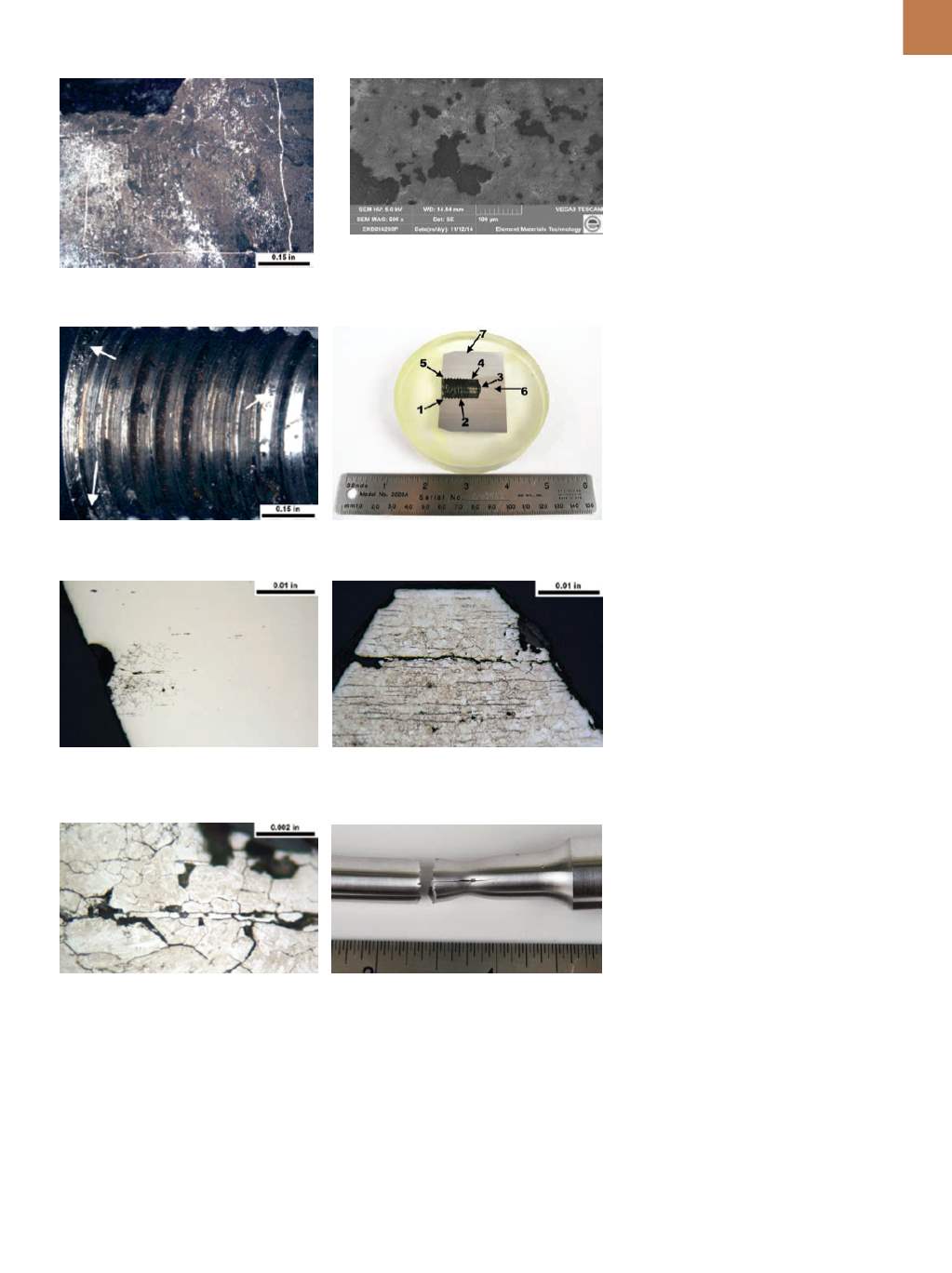

Fig. 5 —

Magnified view of pin threads.

Arrows indicate corrosion pits.

Fig. 6 —

Section MA includes locations 1

through 7, which were closely examined.

Fig. 7 —

Magnified view of location 3. A pat-

tern of branched cracks is present adjacent to

a corrosion pit.

Fig. 8 —

Magnified view of a thread crest at

location 2. Microstructure consists of martensite

and semi-continuous stringers of delta ferrite.

Fig. 9 —

Higher magnification view of right

center of Fig. 8. Cracking progressed along

grain boundaries and delta ferrite stringers.

Fig. 10 —

Fractured tensile specimen exhibits a

longitudinal crack on the bar.

TENSILE TEST RESULTS

The ultimate strength of the ten-

sile specimen was 1200 N/mm

2

and

exceeded the maximum requirement

of 1050 N/mm

2

. The fracture on the

tensile specimen is shown in Fig. 10,

which exhibits a longitudinal crack on

one half of the specimen that partial-

ly split the piece. Splitting was caused

by the semi-continuous delta ferrite

stringers, which indicates that the ma-

terial was brittle in the pin’s longitudi-

nal direction.

CHARPY V-NOTCH

IMPACT TESTING

Charpy V-notch specimens were

excised from the pin with the notches

oriented longitudinally. The result for

each test was 2 Joules, which did not

meet the requirement of 25 Joules.

Longitudinal features were present on

the fracture surfaces that were asso-

ciated with delta ferrite stringers. This

low impact strength was caused by the

semi-continuous delta ferrite stringers.

CONCLUSIONS

Pin cracking initiated at the

threaded hole where there was corro-

sion pitting and evidence of SCC. The

cracking is thought to have progressed

via corrosion fatigue or brittle overload

fracture. The microstructure of the pin

consisted of semi-continuous delta fer-

rite stringers in a matrix of martensite.

These stringers were found to be a ma-

jor factor contributing to the pin failure.

The Charpy V-notch impact resistance

of the steel was far below the specified

requirement. Semi-continuous delta

ferrite stringers made the pin’s impact

resistance very low. Splitting of the ten-

sile specimen was due to the presence

of semi-continuous delta ferrite string-

ers and indicates that the material was

susceptible to longitudinal cracking un-

der the application of stress.

~AM&P

Formore information:

Craig Schroeder

is senior engineer, metallurgy, Element

Materials Technology, 3200 South 166th

St., New Berlin, WI 53151, 262.901.0534,

craig.schroeder@element.com,www. element.com

.

Fig. 3 —

Magnified view of location 1, indi-

cated by scribe marks.

Fig. 4 —

Scanning electron micrograph of

location 1. Post-fracture mechanical rubbing

damage obscures fracture features.

METALLOGRAPHY FEATURES

Section MA is presented in Fig. 6,

in which locations 1 through 7 were ex-

amined. A magnified view of location 3

is shown in Fig. 7, which exhibits a pat-

tern of branched cracking, indicative of

SCC. Magnified views of location 2 are

presented in Figs. 8 and 9. The micro-

structure was found to consist of mar-

tensite and semi-continuous stringers

of delta ferrite, with much of the crack-

ing through the tooth occurring along

the stringers. The presence of these

semi-continuous stringers was deter-

mined to be a major contributing factor

to the pin failure.