A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

3 7

produce amorphous material—until a

few years later when x-ray diffraction

showed that no matter how far grains

are distorted, they still retain their

crystalline structure. As late as 1924,

Jeffries could find no solution to grain

boundaries other than the amorphous

cement theory.

Jeffries took another consulting

assignment at the Aluminum Casting

Co. The company was having problems

with casting defects in parts being ex-

ported to countries allied against Ger-

many in WWI. Even though the compa-

ny was partially owned by Alcoa, they

did not have the knowledge to help

their customers with technical prob-

lems. This work led to Jeffries’ expertise

in aluminummetallurgy.

In 1917, he ended his teaching ca-

reer and enrolled in a graduate program

at Harvard University under Albert Sau-

veur. Jeffries spent a year in residency

at Cambridge with his family, though it

was an unusual time for him to leave his

consulting practice with the war going

on. He then returned to Cleveland to

finish his degree by publishing his work

“Grain Structure in Metals.”

ALLOY DEVELOPMENT

In 1920, Alcoa acquired the Alumi-

num Casting Co. laboratory for nonpay-

ment of aluminum purchases, so Jef-

fries was now a consultant to Alcoa. He

was joined by Robert Archer, a recent

chemical engineering graduate from

the University of Michigan. Jeffries and

Archer worked on improved alloys for

forging and casting during the 1920s,

sharing patents and papers on all their

work. During this time, they invented

casting alloys using 5% and 7% silicon

(355 and 356), an aluminum-copper

alloy (195), an aluminum-magnesium

alloy (220), and an automotive piston

alloy (132) containing 12% silicon. Their

new forging alloys included adding

0.75% silicon to Duralumin (14s) and

a copper-free alloy containing magne-

sium and silicon (25s). Alloy 25s would

be used to make aircraft propellers

during WWII. Jeffries and Archer shared

in 10 patents and 13 published papers

during this decade, and coauthored the

book

The Science of Metals

in 1924.

This assignment, along with his

work at General Electric, lasted through-

out the 1920s. Jeffries was joined by

many new metals researchers who

would train under him and make a rep-

utation of their own in later years. One

of these associates was Edgar Bain, who

worked with Jeffries on problems with

high-speed tool steels that failed during

the drawing of tungsten wire. They pub-

lished a research paper on slip interfer-

ence by alloy carbides for the secondary

hardening of these steels. This theory

was accepted until it was refined when

dislocations were discovered to be the

mechanism for plastic deformation.

Jeffries remained at Alcoa until

1936 when he left to assume full-time

duties at General Electric. Of all the years

heworkedat Alcoa, itwas just apart-time

assignment while he continued to serve

as a consultant at General Electric. This

dual arrangement provided him with an

incomewell abovemost engineers of the

time. His new full-time career at General

Electric included primary responsibility

for developing a commercial business

in tungsten carbide tools. This was an

area of technology that interested Jef-

fries after Samuel Hoyt showed him that

the new tungsten carbide tooling could

solve the problem of machining the new

high-silicon piston alloy. Tungsten car-

bide later became a tool material that

was ideal for severe machining applica-

tions and Jeffries played a large role in

promoting this business into a major in-

dustry. After WWII, Jeffries was appoint-

ed a vice president of General Electric’s

new chemical division.

AWARDS AND HONORS

Among Jeffries’ many awards are

ASM’s Albert Sauveur Achievement Award

in 1935, ASM’s first Gold Medal Award in

1943, and the prestigious John Fritz Med-

al in 1946. He was elected to the National

Academies of Science, Engineering Divi-

sion in 1939, and served as a consultant

to Arthur Compton during WWII on the

Manhattan Project. For his wartime work,

Jeffries was awarded the Medal for Merit,

the highest civilian honor by the U.S. gov-

ernment. During his active career, Jeffries

played leading roles in several technical

organizations, including serving as presi-

dent of the American Society for Metals in

1929. Among his peers, Jeffries was con-

sidered the elder statesman of American

metallurgy. After retirement, he served

as chairman of the ASM World Congress

in 1951 and again in 1956. Jeffries died of

cancer in 1965 at age 76.

For more information:

Charles R. Simcoe

can be reached at

crsimcoe1@gmail.com.

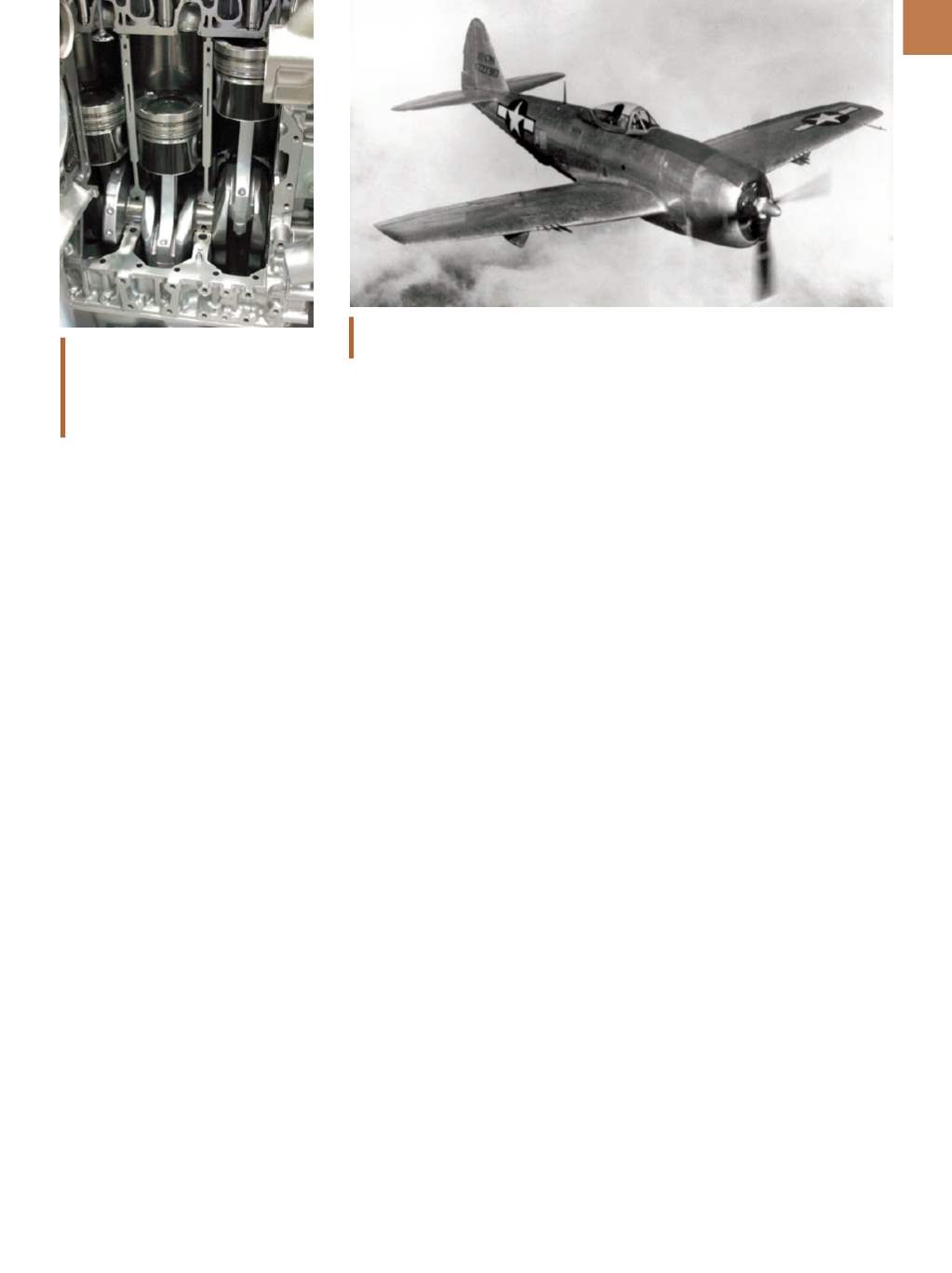

Automotive engine pistons, cross-sec-

tional view. Jeffries and Archer devel-

oped an aluminum-silicon alloy used in

auto engines since the 1920s. Courtesy

of Mj-bird, Wikimedia Commons.

Jeffries and Archer developed a forging alloy for propellers used on WWII aircraft, such as the

Republic P-47N Thunderbolt shown here. Courtesy of U.S. Air Force.