A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 5

3 2

CASE STUDY

FAILURE ANALYSISOF

A FRACTURED PIN

A pin used to hold the side plates together in a conveyor chain system

fractured and failed, prompting a metallurgical failure analysis.

A

pin that was used as part of a

conveyor chain application failed

in service. The company want-

ed to find out what went wrong, so they

submitted the fractured pin to a failure

analysis laboratory for metallurgical

inspection. Loading applied to the pin

was expected to be shear in nature, and

perpendicular to the 59-mm-diameter

surface at the ends of the pin. Specifical-

ly, the owner of the failed pin wanted to

determine if inclusions may have caused

the failure, if the part had been properly

heat treated, andwhether or not the steel

composition was correct.

VISUAL INSPECTION AND

SEM-EDS ANALYSIS

Both visual inspection and scan-

ning electron microscopy/energy dis-

persive x-ray spectroscopy (SEM-EDS)

were initially used to study the failed

pin (Fig. 1). Longitudinal fracture surfac-

es are shown in Fig. 2, with blue arrows

indicating the fracture origin region and

white arrows indicating the cracking

direction. Section MA was selected for

metallography and locations 1 through

3 were chosen for closer inspection.

A magnified view of location 1 is

shown in Fig. 3, which also exhibits sub-

stantial post-fracture rubbing damage.

A scanning electron micrograph of lo-

cation 1 is presented in Fig. 4, although

the rubbing damage obscures the origi-

nal fracture features. Verification of the

fracture mode could not be established

due to the rubbing damage.

A deposit at location 2 was ana-

lyzed using EDS, which detected a trace

amount of chlorine in addition to a few

other foreign elements. Chlorides are

known to be corrosive to stainless steel

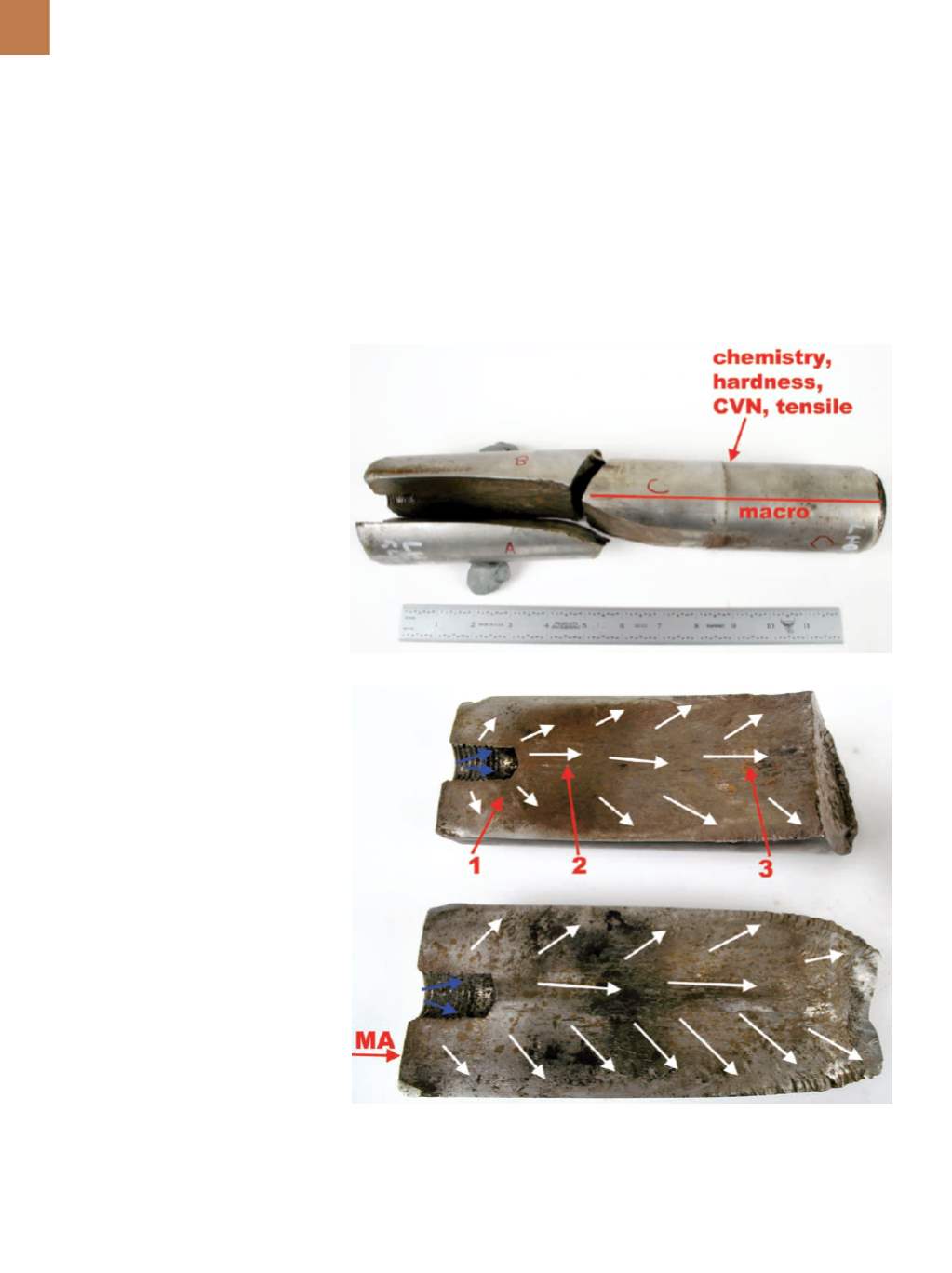

Fig. 1 —

Remnants of the failed pin are shown with sections identified as A through C.

Fig. 2 —

Fractures on sections A and B are shown with section MA selected for metallog-

raphy. Locations 1 through 3 were selected for closer inspection. Blue arrows indicate the

fracture origin region while white arrows show the direction of cracking.

and can contribute to stress-corrosion

cracking (SCC). Threads from the hole at

the origin region are shown in Fig. 5 and

corrosionpits canbe seenon the threads.