A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

3 1

how hot the area is and where the pow-

er dissipation occurs in the logic block.

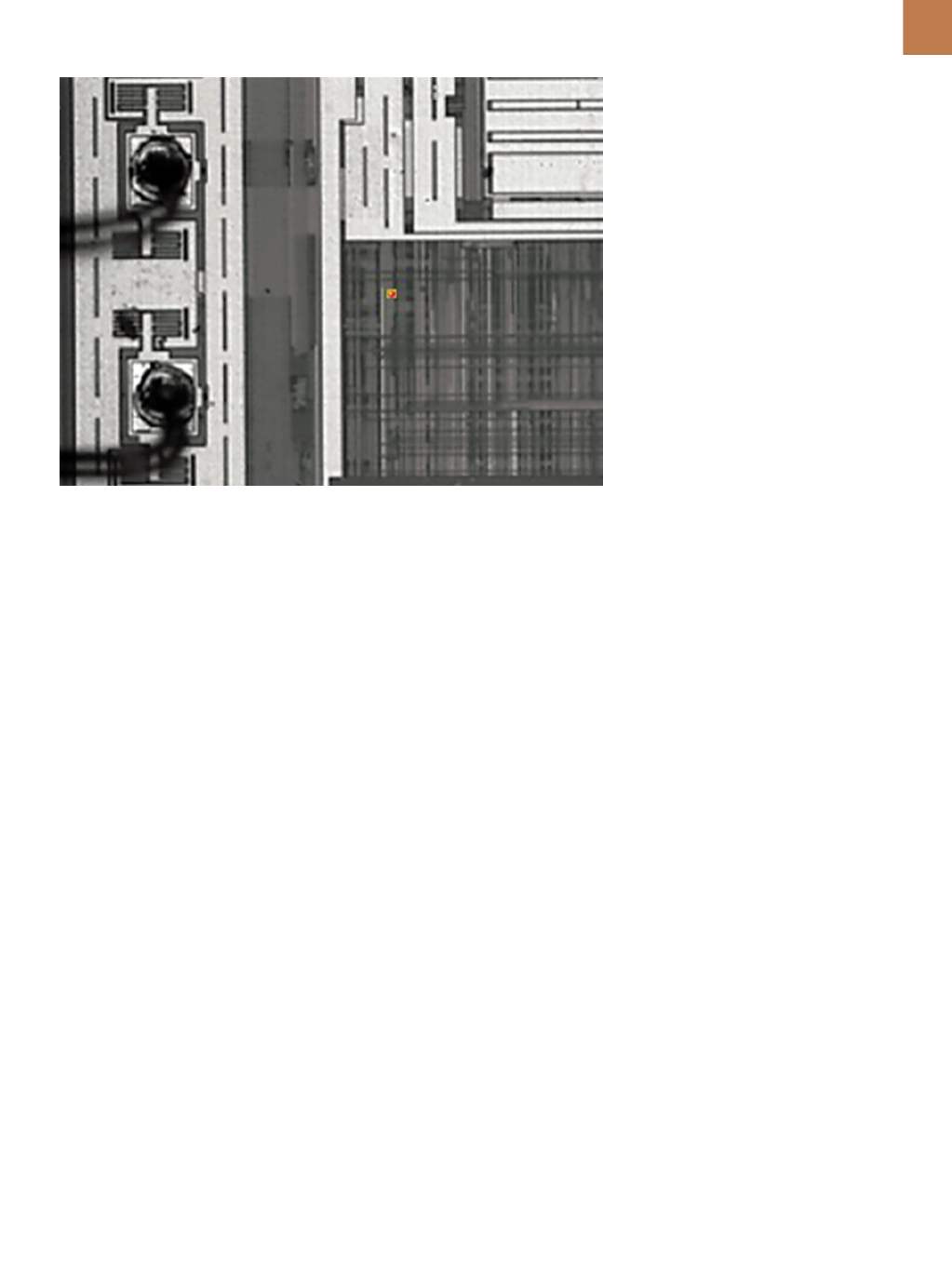

Another defect localization tech-

nique is light emission microscopy, also

known as EMMI. It can be used from

either the front or back of the die (of-

ten without die thinning) to discover

defects or abnormal device operation

based on photon emission in the vis-

ible and near-infrared (IR) spectrum.

These defect-related emissions are of-

ten associated with forward or reverse

biased p-n junctions. In the example of

forward-biased p-n junctions, device

emission is generated by placing a large

number of electrons and holes in close

physical proximity where they recom-

bine and generate light with spectra

centered around the silicon bandgap.

This light can be captured with a sensi-

tive charge-coupled device (CCD) or in-

dium gallium arsenide (InGaAs) camera

in a light-tight box. Two images are cap-

tured, one with the microscope light on

to acquire the die image, the next with

the light off and bias applied to see the

emission source (Fig. 4).

Defect-related photon emissions

are also generally associated with tran-

sistors in saturation, latch-up, and gate

oxide breakdown. In avionics applica-

tions, these types of failures can be the

result of single event effects (SEE), a

category of isolated electronic circuitry

changes resulting from interactions with

high-energy particles and radiation in

space. For instance, a single event latch-

up (SEL) can cause a transistor element

to become fixed in either an on or off

state, or a memory bit to become stuck

at either a one or zero, latching the ef-

fected cell into a permanent state. Latch-

ups, in particular, shine very brightly

using light emission microscopy. Re-

gardless of device type, any transistor

under normal operation will generate a

small amount of light. All light emission

sites are overlaid on a background die

image, enabling failure localization in

relation to circuit features.

Laser signal injection microscopy is

another important imaging tool, and is

used to locate IC defects such as shorts,

junction defects, and problems with

vias. A laser beam is scanned through

a microscope lens over the die while

watching for laser-induced shifts in the

device current-voltage (I-V) response.

Short-wavelength lasers inject photo-

currents and can reveal failure sites

in transistors and p-n junctions, while

longer-wavelength lasers create local-

ized heating that results in temporary re-

sistance changes. In the latter example,

leakage paths can be revealed due to the

temperature coefficient of resistance.

It is also useful to look at the re-

flected laser light image and its am-

plitude using laser timing probe (LTP)

techniques. Because the brightness of

the reflected laser changes with the volt-

age on the transistor, an individual tran-

sistor’s waveform can be measured by

running a logic pattern through the sam-

ple. It is also possible to see what is not

switching, as well as locations that are

switching at a certain clock or data fre-

quency, or where a clock stops halfway

through, helping to localize the defect.

Localizing failures at the transis-

tor level may also require nanoprobe

techniques. Polishing the sample expos-

es contacts, and a biased probe tip is

scanned across its surface to reveal sub-

tle leakage differences between sources,

drains, and gates. Another option is to

drop up to six probes onto the transistor,

make contact at the source, gate, drain,

and body, and measure the electrical

characteristic of each individual tran-

sistor. Electrical characteristics such as

threshold voltage, off leakage, and on

current can then be measured. Once the

problem transistor has been identified,

physical analysis can take place.

Transmission

electron

micro-

scopes (TEMs) are often used after

nanoprobe tests. Samples are placed

under a focused ion beam and trenches

are dug on each side of the target tran-

sistor, leaving only a slice the size of the

transistor itself. This slice is viewed un-

der the TEM to visualize defects in a way

that no other technology can.

Avionics system failures are diffi-

cult to identify and solve. The combina-

tion of smaller and more complex de-

vices used in demanding environments

makes it difficult to find and fix failures.

Identifying, localizing, and resolving

failures requires a highly disciplined

process, supported by numerous so-

phisticated test and imaging tools. With

the right approach, it is possible to iso-

late a failure’s root causes, understand

its mechanisms, and resolve it.

~AM&P

For more information:

Winfield Scott

is technology director, Evans Analytical

Group, 2710 Walsh Ave., Santa Clara, CA

95051, 408.454.4600,

wscott@eag.com,

www.eag.com/mte.Fig. 4 —

Emissionmicroscopy requires little or no sample preparation, other than decapsulation.