A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 5

3 0

across adjacent conductors and, at high

altitudes, these shorts can result in con-

ductive plasma generation.

Other nondestructive tests include

a superconducting quantum interfer-

ence device (SQUID) and giant magne-

toresistive (GMR) microscopy. Both are

magnetic current imaging tools useful for

finding shorts and leakages, and map-

ping their locations on the current path.

Thermal imaging can also be used to

identify and map hot spots and provide

actual temperature measurements. An-

other common nondestructive electrical

test is curve trace. Voltage and current

are swept to create an I-V plot, which re-

veals opens and shorts as well as resis-

tance and leakage, helping to verify and

visualize the electrical failure signature.

Nondestructive package tests in-

clude particle impact noise detection

(PIND) for cavity packages, which is es-

sentially a process of shaking the sam-

ple and listening for loose particles in-

side. Fine and gross leak tests are both

used for evaluating hermetic package

integrity. In addition, 2D or 3D x-ray

imaging is useful for analyzing package

integrity and provides a look at PCB in-

ternal traces, bond wires, die bumps,

de-attached fillets, substrate package

traces, and other package elements.

Scanning acoustic microscopy (SAM)

uses ultrasound pulse echo techniques

to look for voids, cracks, and delamina-

tions in ceramic capacitors and plastic

packages. Also, TDR can be used here to

help determine whether an open/short

defect is in the package or at the inter-

face to the die. Other nondestructive

optical tests include filtered polarized

light inspection, as well as die backside

inspection using reflected IR imaging.

Based on the electrical failure sig-

nature and initial nondestructive test-

ing results, a plan for physical analysis

can be formulated. At this point, inter-

nal visual inspection using low- and

high-magnification optical microscopy

is often used to further localize the prob-

lem. Optical and scanning electron mi-

croscope (SEM) inspection can also help

analysts understand morphology and

electrostatic discharge (ESD) issues, and

can be combined with materials charac-

terization tests to identify foreign ma-

terials or corrosive byproducts such as

chlorine that would indicate problems

related tomoisture infiltration.

Rounding out the options for

package testing are backside infrared

(IR) thermography and other back-

side laser inspection techniques, and

cross-sectioning to look at joint profiles

with SEM and other higher-resolution

instruments.

LOCALIZING FAILURES TO

THE TRANSISTOR LEVEL

Once an electrical failure has been

identified through nondestructive test-

ing, the failure mechanism must then

be localized to within a few microns of

the problem’s exact location. Analysts

use optical microscopy to look at bond

wires, die attach, big cracks in the die,

electrical overstress, corrosion, and

other large elements on the die. Wire

bonds are a particularly vulnerable de-

sign element in avionics systems, which

are prone to intermetallic formation due

to exposure to elevated temperatures,

corrosion due to both high temperature

and moisture, and fatigue due to tem-

perature cycling exposure (Fig. 2).

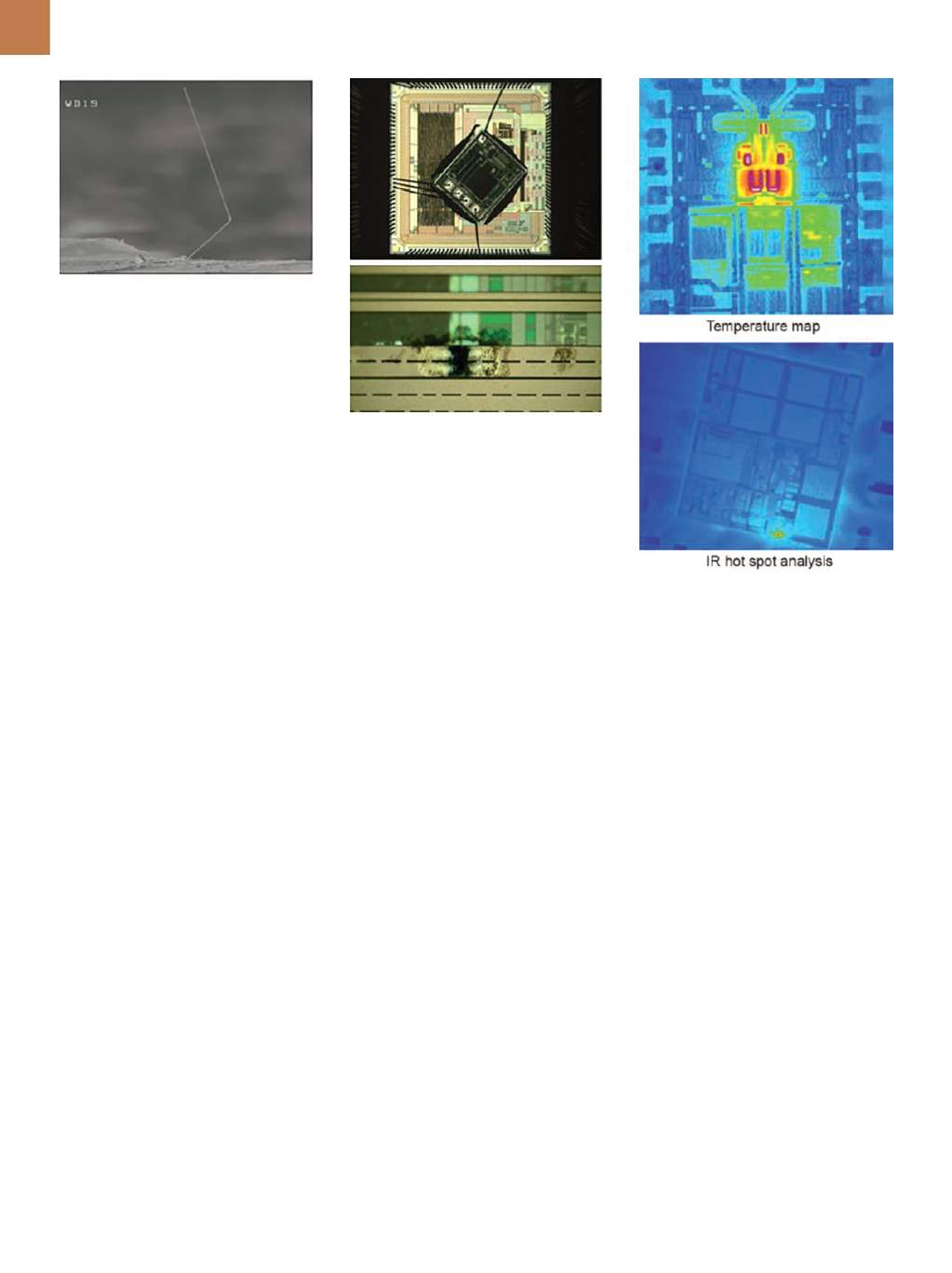

Infrared thermography is another

important technique. Avionics packages

are frequently exposed to temperatures

higher than the maximum allowable for

their electronics, reducing component

lifetimes and significantly increasing

failure probability. Infrared thermog-

raphy microscopes localize hot spots

by measuring true temperature with

pixel-by-pixel emissivity correction.

Heat is imaged at a 3-micron infrared

wavelength to create a color-coded tem-

perature map or hot spot overlay image.

Figure 3 shows two examples

where power was dissipated in the sam-

ple and creating hot spots. Temperature

increase depends on the power dissi-

pated per unit area, so in this case iden-

tifying where the device was getting hot

is easy. Infrared thermography indicates

Fig. 1 —

Scanning electron microscope

image of tin whiskers.

Fig. 2 —

Low- and high-magnification

microscopes can be used to visualize a

package’s wires and wire bonds, passivation

cracks, electrical overstress, and corrosion.

Fig. 3 —

Temperature gradient across the

die, top, and location of a gate oxide break-

down site, bottom.