A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

2 5

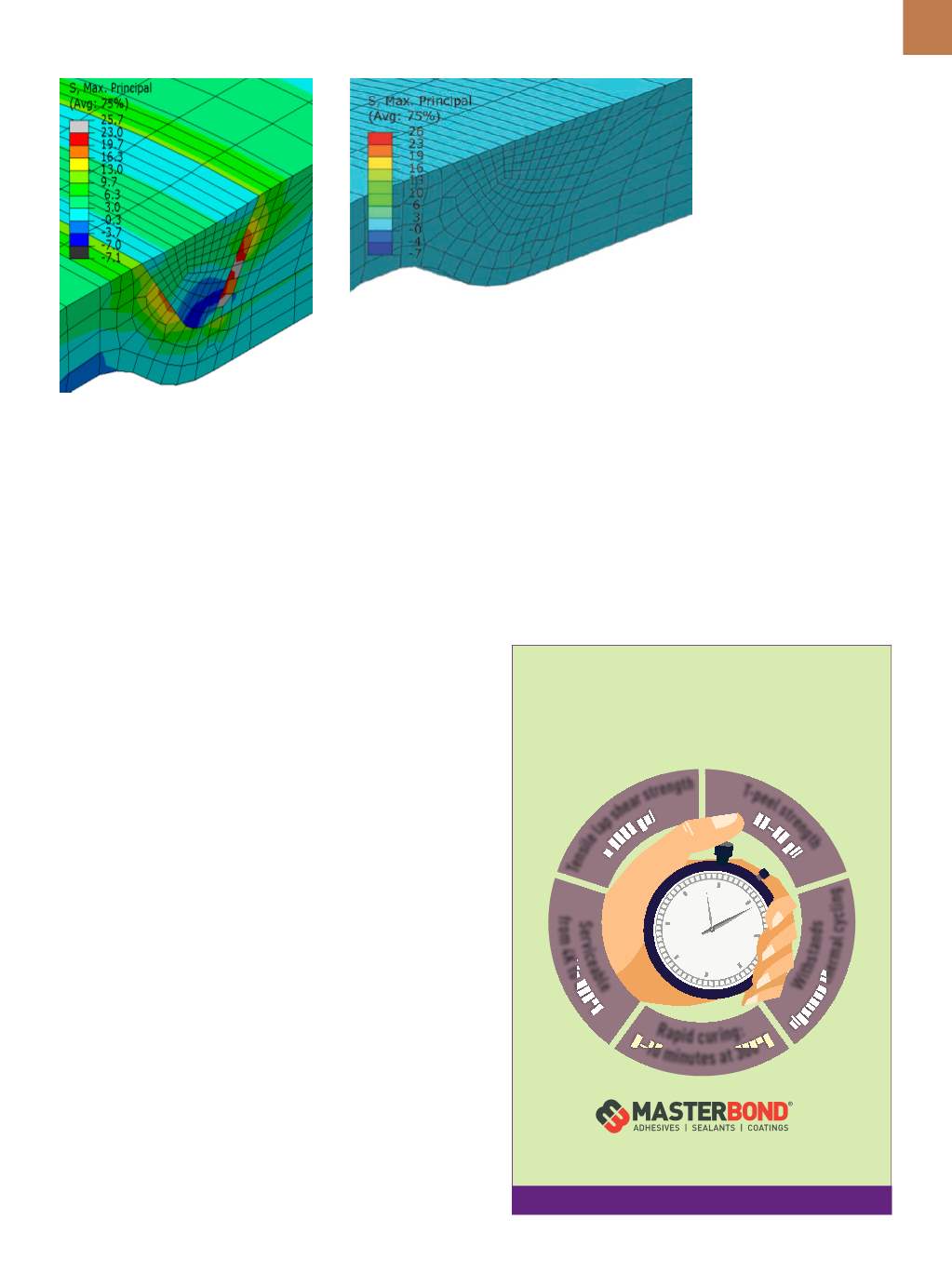

Fig. 8 —

Predictedmaximumprincipal stress

for welding with flux-cored arc welding.

Fig. 9 —

Predictedmaximumprincipal

stress for welding with electron beam

welding.

the weld (N117) and the base metal

(MO-RE1). This stress distribution could

explain the crack type A observed in the

weld macrograph, as shown in Fig. 3.

Electron beam welding (EBW)

without filler metal could eliminate the

high stress near the weld (Fig. 8). Anoth-

er FEA was conducted by replacing the

material properties in the weld using

base material properties and keeping

other conditions the same. Figure 9

shows the predicted maximum princi-

pal stress with EBW without using filler

metal. High stress near the weld dis-

appears, as shown in Fig. 9. Therefore,

EBW is an effective method to improve

the creep-fatigue life of the furnace roll

in the hot-dip coating line. A prelimi-

nary welding test shows that EBW could

be used to weld the furnace roll.

SUMMARY

A longstanding problem with hot-

dip coating lines is that the furnace roll

often fails in less than one year. By exam-

ining the service history of a failed roll, it

was discovered that the furnace roll was

working under conditions involving both

thermal and mechanical cyclic load-

ing, in addition to high temperatures.

Therefore, creep-fatigue damage could

occur during roll service. Macroscopic

examination of the welded joint found

two kinds of cracks—crack A at the weld

root and crack B at the weld toe. Crack

type A initiated from the weld root and

www.masterbond.com Hackensack, NJ 07601 USA +1.201.343.8983 • main@masterbond.com Beat the clock f r o m 4 K t o 4 0 0 ° F 5 – 1 0 m i n u t e s a t 3 0 0 ° F r ig o r o u s t h e r m a l c y c l i n g S e r v i c e a b l e R a p i d c u r i n g : W i t h s t a n d s > 3 2 0 0 p s i 2 0 – 2 5 p l i T e n s i l e l a p s h e a r s t r e n g t h T - p e e l s t r e n g t h with F A S T C U R I N G S T R U C T U R A L A D H E S I V E S U P R E M E 1 0 H T F 11063LK_3.25x4.875_Supreme10HTF-1.indd 1

8/26/15 4:25 PM

propagated to the outer surface of the

weld, which resulted in separation be-

tween the roll shell and end bell. Defects

such as inclusions and incomplete joint

penetration were also found.

A new furnace roll design was pro-

posed to avoid the through-weld crack

in which the weld was rotated by 90

°

. In

addition, the roll material was replaced

with MO-RE1. Finite element analysis

was used to evaluate

the new design. Re-

sults show that high

stress occurs in the

interface between the

weld and base metal,

which is induced by

the difference between

the thermal expansion

coefficient of the weld

and base metal. Elec-

tron beam welding

without filler metal

can eliminate the high

stress near the weld.

Therefore, the new

design, in conjunction

with the new welding

process, could solve

the historical roll fail-

ure problem.

~AM&P

For more information:

Yu-Ping Yang is princi-

pal engineer, model-

ing group, EWI, 1250

Arthur E. Adams Dr.,

Columbus, OH 43221,

614.688.5253,

yyang@ ewi.org,

www.ewi.org.References

1. G.H. Awan, TheMorphology of Coating-

Substrate Interface inHop-Dip-Aluminized

Steels, University of Engineering and

Technology, Pakistan, Ph.D. dissertation,

2001.

2. C.M. Cotell, J.A. Sprague, and F.A.

Smidt,

ASM Handbook,

Volume 5:

Surface Engineering,

p 339-348, 2007.

3. M.B. Isiko, Aluminizing of Plain

Carbon Steel—Effect of Temperature

on Coating and Alloy Phase

Morphology at Constant Holding

Time, Norwegian University of Science

and Technology, TMT4905 - Materials

Technology, Masters thesis, 2012.