A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

2 1

P

rocessing engine components

such as crankshafts, gears, shafts,

springs, rotors, cylinder heads, and

engine blocks poses several difficulties

for manufacturers. For example, manu-

facturing a finished product with the su-

perior material characteristics required

for a given application is often challeng-

ing. Among the characteristics of interest,

residual stress can have a significant im-

pact on the effective service life of engine

components. Because residual stresses

are introduced in nearly every step in

manufacturing, the effect of processing

on failure-critical locations must be well

understood, controlled, and optimized.

The x-ray diffraction (XRD) tech-

nique can be used to characterize re-

sidual stresses in crankshafts and is of-

ten the only viable method to measure

these stresses at certain failure-critical

locations, for example, in the rolled

fillet radius of a crankshaft. Surface

residual stress measurements can be

performed nondestructively for inline

quality control and for tracking stresses

through processing and in-service cy-

cling. Crankshaft subsurface gradients

can also be evaluated at various stages

of manufacture to benchmark the ef-

fects of each manufacturing process.

The service life of engine compo-

nents often varies greatly as a result of

as manufactured

residual stress levels

found in failure-critical locations. With

increased demand from consumers for

quality, reliability, and seamless perfor-

mance, manufacturers must meet or ex-

ceed specified warranty periods and re-

duce recalls and warranty repairs. Thus,

the stress state of critical components

must be accurately characterized so that

contributingmechanisms and sources of

potentially harmful residual stresses are

well understood. Fabrication process-

es can then be modified and optimized

to ensure high-quality components are

manufactured at a competitive cost.

CHARACTERIZING

RESIDUAL STRESS

When residual stress is thought to

be a contributing factor to premature

failure, such suspicions may be validat-

ed by both experiment and measure-

ment. XRD can also be used to verify

the effectiveness of heat treatment pro-

cesses and the impact of surface treat-

ments such as grinding, turning, rolling,

or shot peening.

In order to increase crankshaft

life, fillets are commonly burnished

or rolled to introduce sufficient com-

pressive residual stresses that inhibit

initiation and propagation of fatigue

cracks. The effect of the rolling process

is often characterized as a function of

depth because stress gradients normal

to the rolled surface are introduced

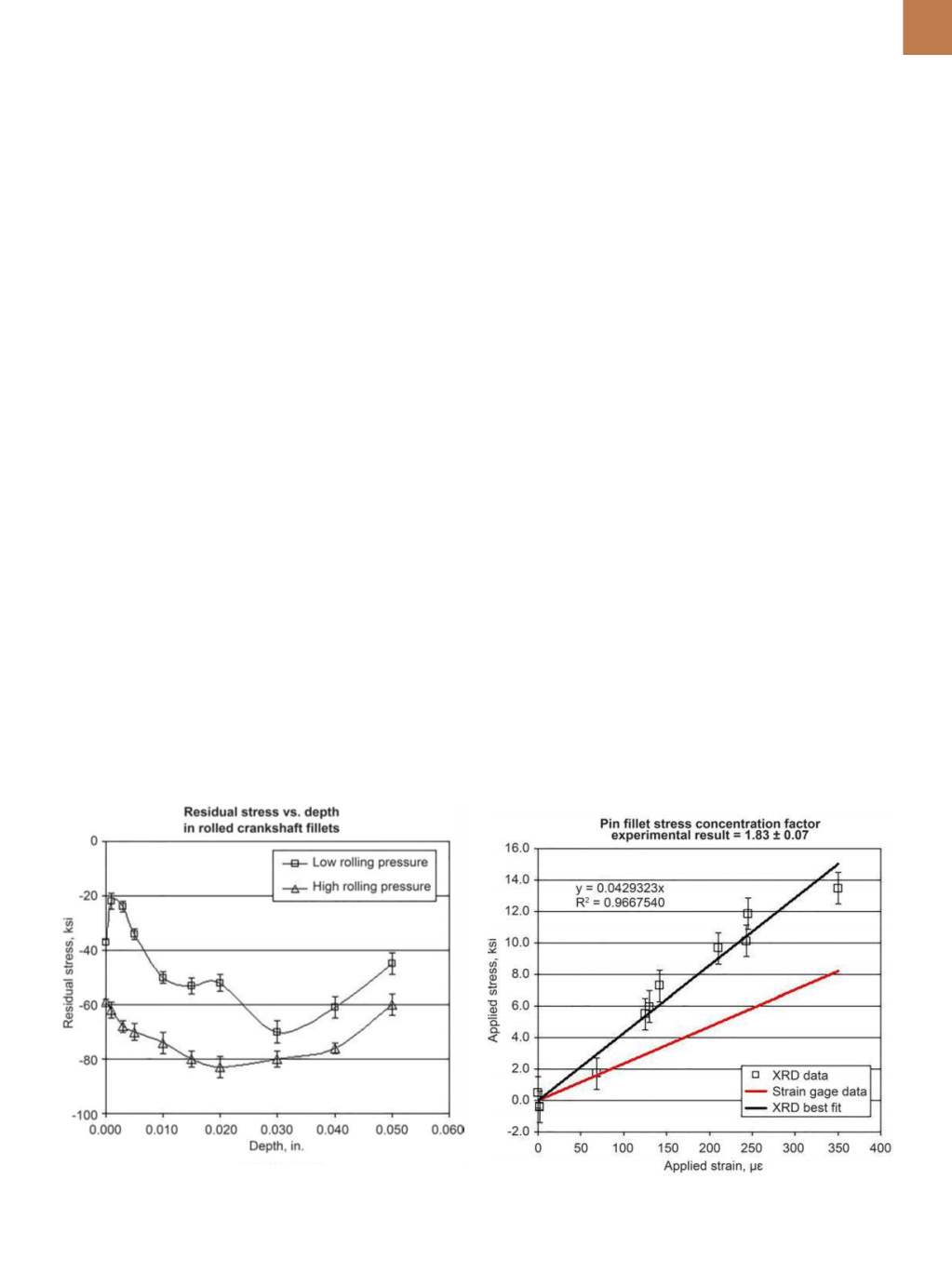

by the process. Residual stress versus

depth profiles are also typically collect-

ed at different angles around the cir-

cumference of the fillet because man-

ufacturers often vary rolling pressure

with angular position around the fillet

(Fig. 1). This is particularly important

in the case of pin journals, especially

when a split pin design is used. In order

to segregate rolling induced stresses

from those caused by heat treatment

and other cold working processes, re-

sidual stress as a function of depthmust

be characterized at various stages. This

also includes effects that result from

any straightening processes potentially

applied as a final manufacturing step.

Stress concentration factors (SCFs)

used to estimate applied loads in ser-

vice are often based on calculation or

modeling, or quoted from literature.

XRD techniques have been used to ex-

perimentally measure the effective SCF

for a given undercut radius geometry.

As an example, known bending loads

were applied to a test crankshaft and

stress as a function of applied load

was measured in the rolled fillet. The

SCF was experimentally derived from

this data and the result of 1.83 ± 0.07

Fig. 1 —

Residual stress vs. depth profiles collected on a crankshaft

using x-ray diffraction in areas of high pressure and low pressure rolling

in a pin journal fillet radius.

Fig. 2 —

Experimental determination of the stress concentration factor

(SCF) in a pin journal fillet radius.