A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 5

2 2

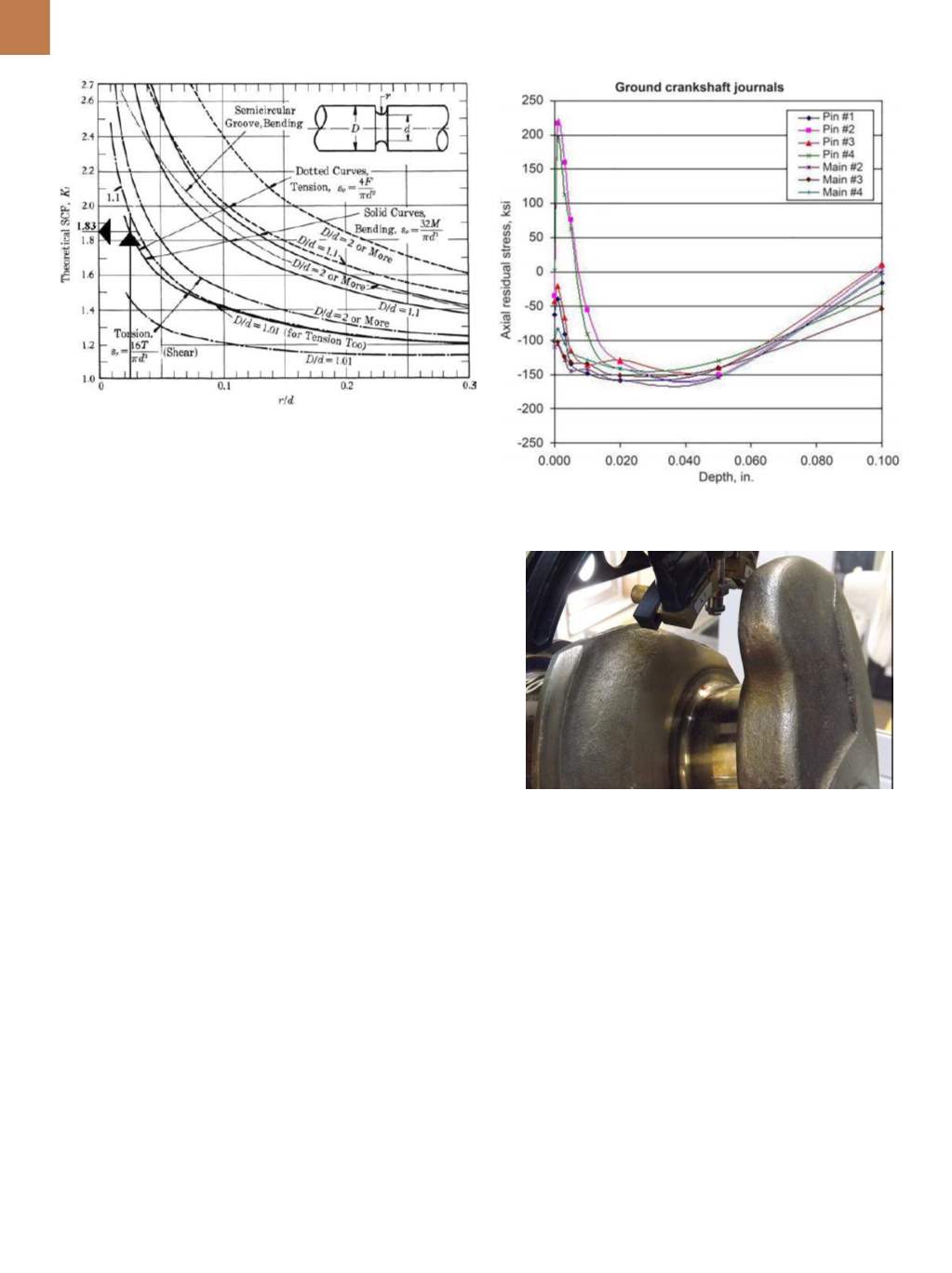

(Fig. 2) agreed with theoretical calcula-

tions within experimental error (Fig. 3).

Main bearing and pin journal sur-

faces are typically precision ground to

obtain the desired dimensional accu-

racy and surface finish. Tensile residual

stresses imparted by grinder burn can

have a significant impact on the life of

a ground journal. Detection and char-

acterization of grinder burn is there-

fore extremely important and can be

performed using XRD. In general, the

maximum tensile stresses due to grind-

er burn (abusive grinding) are found

at shallow depths below the ground

surface of a journal suffering from this

effect. In order to reliably characterize

residual stresses due to grinder burn, it

is necessary to collect subsurface resid-

ual stress profiles (Fig. 4).

When residual stress measure-

ments are required in the hoop direc-

tion of a pin journal in the fillet radius,

they can usually be performed without

sectioning at locations farthest from

the crankshaft axial centerline. How-

ever, in cases where measurements are

required adjacent to counterweights,

or for measurements in the axial direc-

tion of the crankshaft, some section-

ing may be required. This procedure

should be limited to areas where access

of the goniometer is hindered by crank-

shaft geometry or where the incident

or diffracted x-ray beam is shadowed

(blocked). The effects of

sectioning can be char-

acterized by installing a

small strain gage near

the measurement point

in the direction for stress

measurement and mon-

itoring it during the pro-

cess. Subsequent resid-

ual stress measurement

results can be corrected

for relaxation due to sec-

tioning. Current state-

of-the-art instrumenta-

tion that works in both

psi and true-chi modes

(rather than modified

chi) can minimize the need for section-

ing and certain locations can be ac-

cessed without sectioning.

Residual stress measurements

should be performed using the multi-

ple exposure technique (MET) in accor-

dance with SAE HS784 and ASTM E2860

recommended procedures, and equip-

ment should be calibrated to national

standards including ASTM E915.

Subsurface residual stress gradi-

ents can be evaluated for crankshafts

taken from various stages of manu-

facture to benchmark the subsurface

effects of each manufacturing process.

Once contributing mechanisms and

sources of potentially harmful residual

stresses are well understood, fabrica-

tion processes can then be modified

and optimized so that high-quality

components can be manufactured at

a competitive cost. In many cases, this

insight can only be achieved using XRD

techniques.

~AM&P

For more information:

James Pineault

is laboratory director, Proto Mfg. Inc.,

12350 Universal Dr., Taylor, MI 48180,

313.965.2900,

xrdlab@protoxrd.com,

www.protoxrd.com.Fig. 3 —

Theoretical SCF for geometry similar to a pin journal radius.

Fig. 4 —

Residual stress vs. depth profiles for different grinding

parameters.

Fig. 5 —

State-of-the-art Microarea instrument works in both psi

and true chi modes to characterize residual stresses at certain

features on a crankshaft without sectioning.