A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 5

2 4

These temperature variations resulted

in cyclic thermal loading on the roll.

In addition, the mechanical load used

to transport the strip was applied on a

90

°

section of the roll. Because the roll

was rotating continuously, it was also

subjected to a cyclic mechanical load.

Therefore, the furnace roll was working

under conditions involving both ther-

mal and mechanical cyclic loading, in

addition to high temperature. These

conditions could lead to creep-fatigue

damage during service.

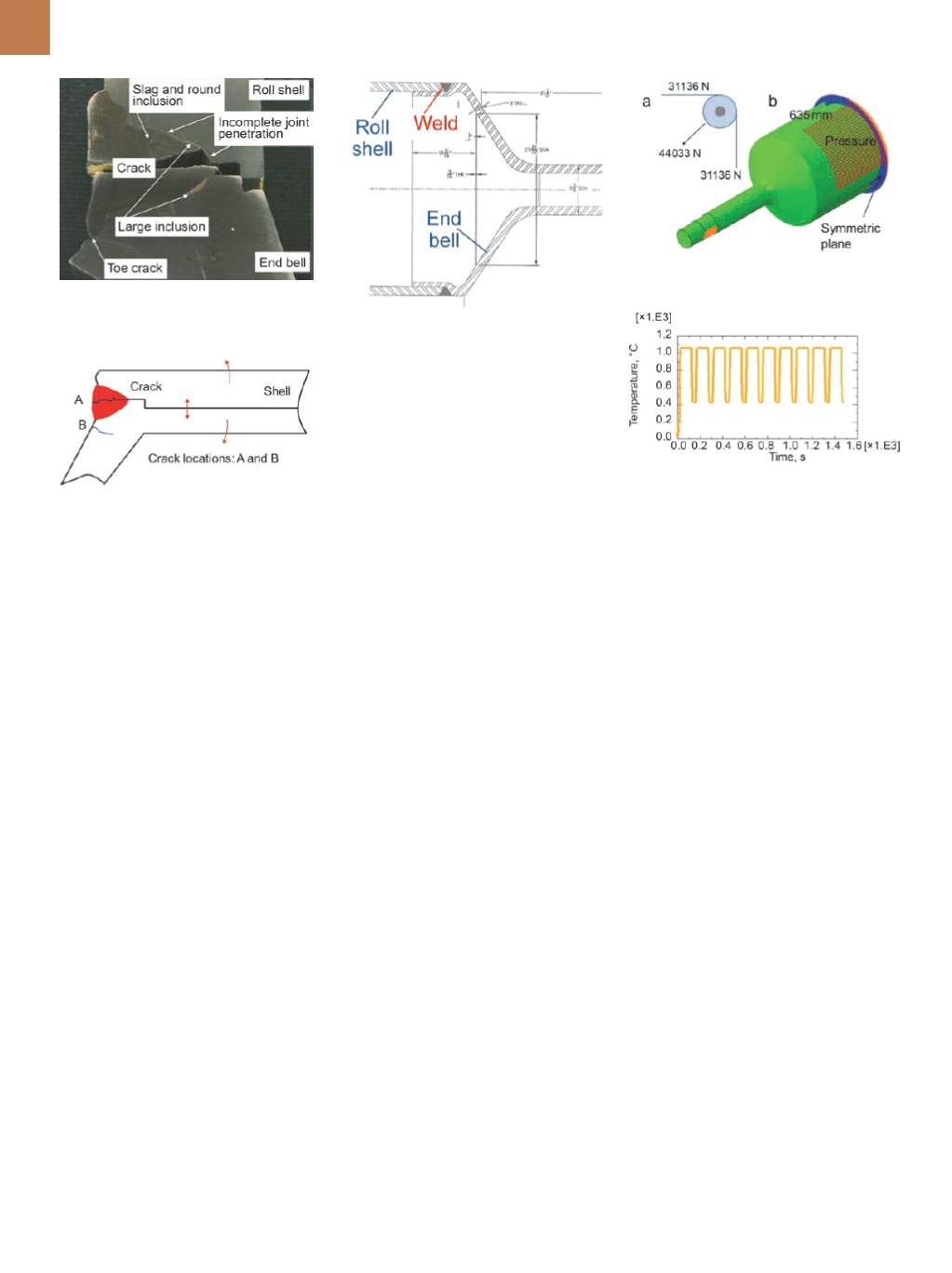

Macroscopic examination of the

welded joint identifies why failure oc-

curred. Figure 3 shows a macrograph of

the weld cross-section prepared by cut-

ting the failed roll. Two kinds of cracks

(Fig. 4, A, B) were found near the weld.

Crack type A initiated fromtheweld root

and propagated to the weld’s outer sur-

face, resulting in a separation between

the roll shell and end bell. Crack type B

appears near the weld toe, which may

be the result of stress concentration

due to geometric discontinuities during

cyclic loading. In addition, defects such

as inclusions and incomplete joint pen-

etration were found in the weld. Al-

though the inclusion did not contribute

to roll failure, the incomplete joint pen-

etration may have triggered the failure

if combined with tensile stress.

FURNACE ROLL REDESIGN

As shown in Fig. 4, the weld root

in the furnace roll’s current design is

a potential crack location due to the

mechanical load from transporting the

steel strip. To avoid the through-weld

crack (crack type A in Fig. 4), the weld

that joins the end bell to the roll shell

was redesigned, as shown in Fig. 5. In

the new design, the weld is rotated 90

°

and moved slightly away from the end

bell to the shell shoulder, which may

further reduce weld stress. Further, the

material (high-temperature alloy 22-H)

used to make the end bell and roll shell

is replaced with MO-RE1.

NEW DESIGN EVALUATION

Finite element analysis (FEA) was

used to evaluate the new furnace roll de-

sign. Due to the symmetry of geometry

and loads, a half FEA model was used in

the analysis. Symmetric boundary con-

ditions were applied in the symmetric

plane, as shown in Fig. 6b. Temperature-

dependent material properties were in-

put to the FEA model for base material

MO-RE1 and filler material N117.

Steel sheet tension of 31,136 N is

transferred to the roll through contact

on 25% of the roll circumference over a

width of 1270 mm in the center of the

roll length and reacted on the journals,

as shown in Fig. 6a. In the FEA model,

forces were combined and converted

into a pressure applied in the 45

°

di-

rection, as shown in Fig. 6b. Finite ele-

ment grids show the pressure applied

surface, which is a 90

°

section in the

designed roll. Gravitational force is also

included in the model. Pressure and

gravity were balanced by supporting

the journal from each end of the roll.

Heat transfer analysis was used

to predict the temperature history of

the welded roll by modeling heat con-

vection from hot air inside the furnace

using Abaqus software and a user-

developed subroutine. The heat flux

(

q

) was calculated using equation (1) in

which the heat convection coefficient

(

h

) was input as a constant number,

20 W/m

2

C.

T

s

represents furnace tem-

perature, which varies by location and

time. Figure 7 is the predicted tempera-

ture on the roll for 10 heating cycles.

q

= h(T – T s )

(1)

Transient, static, stress, and dis-

placement analyses with time-depen-

dent material responses were con-

ducted using the Abaqus commercial

finite element code and inputting the

predicted temperature history. Isotropic

creep and plasticity coupled behavior

was modeled by solving a coupled sys-

tem of constitutive equations. Figure 8

shows the predicted maximum principal

stress after the 10th cycle (Fig. 7). Stress

magnitudes are lowbecause the roll is at

a relatively high temperature of 427

°

C.

High stress is observed in the interface

between theweld and basemetal, which

could be induced by the difference of

thermal expansion coefficient between

Fig. 3 —

Defects and cracks near the welded

joint.

Fig. 4 —

Current furnace roll design.

Fig. 5 —

New furnace roll design.

Fig. 6 —

Mechanical load applied on the roll.

Fig. 7 —

Thermal load applied on the roll.