A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 5

1 6

SURFACE ENGINEERING

COATING TECHNOLOGY

FINDS NEW HORIZONS

Surmet Corp., Burlington, Mass.,

contributed the critically enabling sil-

icon mirror-surface technology for the

LORRI telescope, part of NASA’s New

Horizons mission. The unique and pro-

prietary silicon coating technology is

strongly adherent, amorphous, and

supremely homogeneous at an atomic

scale. The coating applied to the mirror

substrate of the telescope allows for

single point diamond turning and finish

polishing, meeting the most stringent

wavefront specifications required for

capturing ultrahigh resolution images

from outer space. The New Horizons

mission, launched in 2006, is the first

spacecraft to travel to Pluto and the

Kuiper Belt. It traveled for nine years

to reach its milestone closest approach

to Pluto (within approximately 7750

miles) on July 14.

surmet.com.

DEPOSITION TECHNIQUE

CONTROLS NANOWIRE LENGTH

It is now possible to synthesize bi-

metallic nanowires made of silver and

gold whose length can be precisely con-

trolled, thanks to new experiments by

European researchers. Because the wires

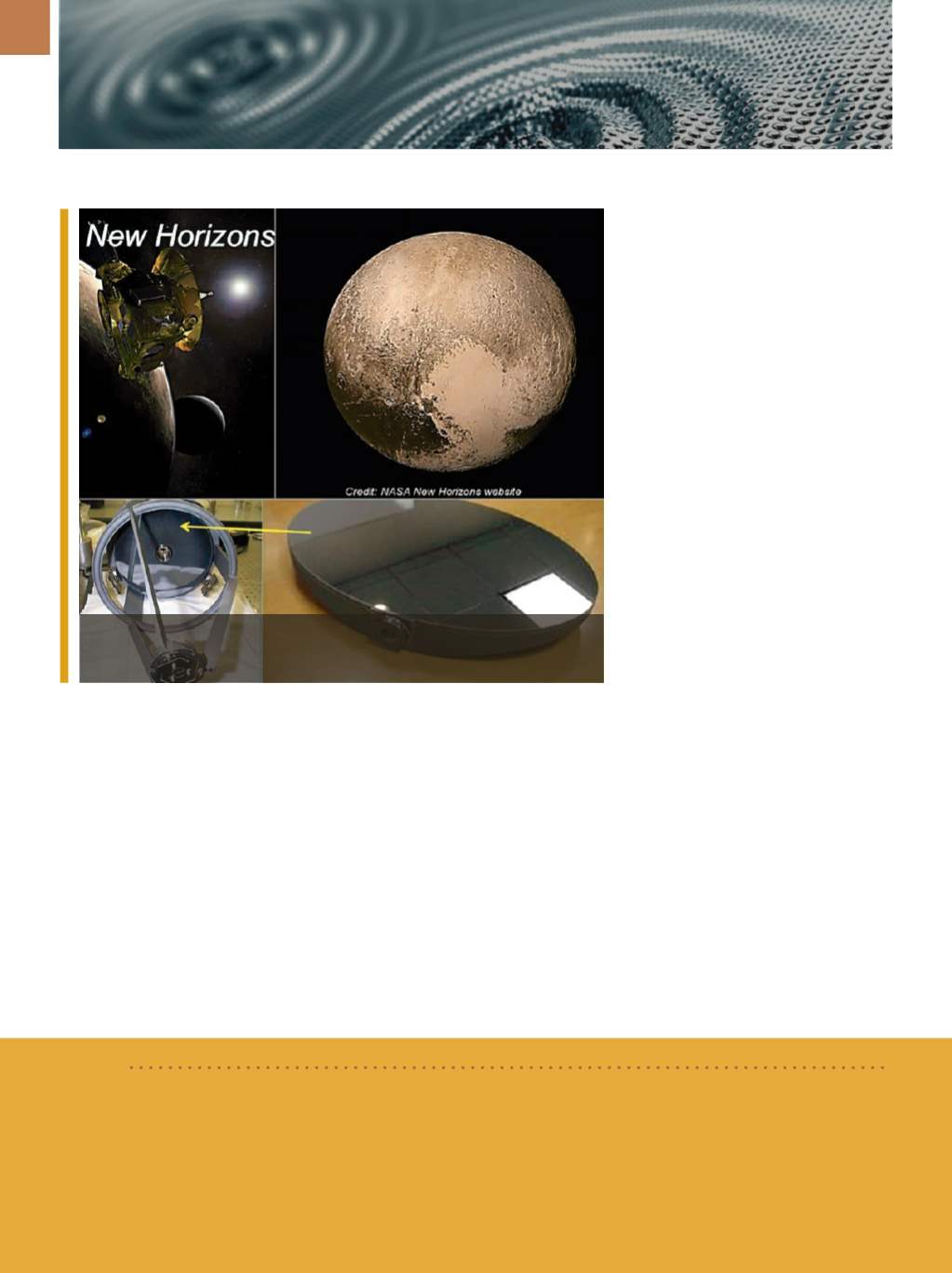

LORRI (bottom left) took the images from the New Horizons spacecraft (top left)

of Pluto (top right). Silicon mirror surface technology from Surmet enabled image

capture (bottom right).

BRIEF

Massachusetts Institute of Technology’s

spinout company

LiquiGlide

licensed its nonstick coating to Norwegian

consumer goods producer

Orkla

for use on mayonnaise products sold in Europe. Developed in 2009, the liquid-

impregnated coating acts as a slippery barrier between a surface and a viscous liquid. Applied inside a condiment

bottle, for example, the coating clings permanently to its sides, while allowing the condiment to glide off completely.

liquiglide.com.

also have roughly the same molecular

weight, their “surface plasmon resonanc-

es” can be tailored too—in the near- and

mid-infrared regions of the electromag-

netic spectrum. These nanostructures

could be used in a variety of different ap-

plications, from metamaterials to solar

energy harvesting and biosensing.

Plasmons are quantized collective

oscillations of electrons confined on the

surface of a metal that interact strongly

with light on the nanoscale. Bimetallic

nanostructures such as nanowires, es-

pecially those made of silver and gold,

are good plasmonic materials. Because

plasmonic nanowires collect and focus

light at optical to near-infrared wave-

lengths, they are crucial for developing

future nanophotonics devices.

To tailor the surface plasmon res-

onances of nanowires for specific ap-

plications, researchers must accurately

control the length of these structures

and synthesize them so that they do

not differ too much in weight and size.

Luis Liz-Marzán of the Centro de Inves-

tigación Cooperativa en Biomateriales,

San Sebastián, and the Basque Foun-

dation for Science in Bilbao, both in

Spain, and others developed a nano

wire growth technique based on selec-

tively depositing silver onto specific

crystallographic facets of prefabricated

gold cores known as pentatwinned gold

nanorods. To obtain highly elongated

nanostructures just microns in length,

researchers avoided secondary nucle-

ation or other side reactions that would

compromise the quality of the finished

product.

www.cicbiomagune.es.