A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 5

1 2

TESTING | CHARACTERIZATION

OPTICAL LENSES MADE

OF NANOPILLARS

A team of researchers recently

developed flat optical lenses as part

of a collaboration between NASA’s Jet

Propulsion Laboratory and the Cali-

fornia Institute of Technology, both in

Pasadena. These optical components

are capable of manipulating light in

ways that are difficult or impossible

to achieve with conventional optical

devices. The new lenses are not made

of glass. Instead, silicon nanopillars are

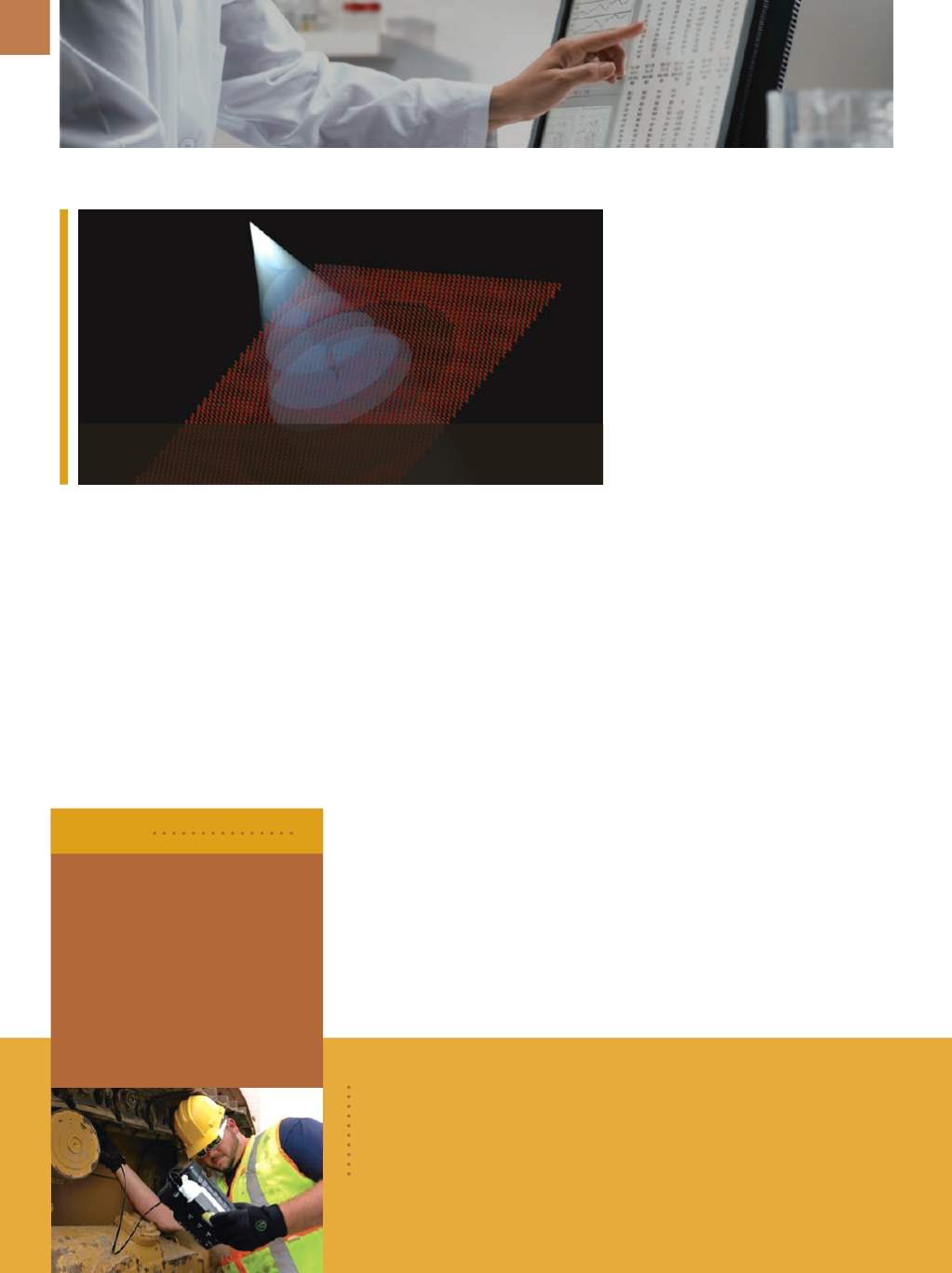

Schematic shows how a metasurface can generate and focus radially polarized light.

Courtesy of Amir Arbabi/Faraon Lab/Caltech.

of each pillar and rotating them around

their axes, scientists were able to simul-

taneously manipulate the phase and

polarization of passing light. In addi-

tion, the new lenses can be used to

modify the shape of light beams at will.

Semiconductor lasers typically emit

into elliptical beams that are difficult

to work with, and the new metasur-

face optical components could replace

expensive optical systems used to circu-

larize the beams. The team is currently

working with industrial partners to cre-

ate metasurfaces for use in commer-

cial devices such as miniature cameras

and spectrometers, although a limited

number are now being used in optical

experiments by collaborating scientists

in other disciplines.

jpl.nasa.gov.ULTRAFAST ELECTRON

DIFFRACTION RESEARCH

SPEEDS AHEAD

A new instrument at the DOE’s

SLAC National Accelerator Labora-

tory, Menlo Park, Calif., uses a method

known as ultrafast electron diffraction

(UED) to reveal motions of electrons

and atomic nuclei within molecules

that take place in less than a tenth of

a trillionth of a second. The technique

complements ultrafast studies with

SLAC’s x-ray free-electron laser. Similar

to x-ray light, highly energetic electrons

can take snapshots of the interior of

materials as they pass through them.

Yet electrons interact differently with

materials and “see” different things.

Combining both methods enables a

arranged into a honeycomb pattern to

create a metasurface that can control

the paths and properties of passing light

waves. Applications include advanced

microscopes, displays, sensors, and

cameras that can be mass-produced

using the same techniques used to

manufacture computer chips.

“Currently, optical systems are

made one component at a time, and

the components are often manually

assembled,” says Andrei Faraon, assis-

tant professor of applied physics and

materials science at Caltech. “But this

new technology is very similar to the

one used to print semiconductor chips

onto silicon wafers, so you could con-

ceivably manufacture millions of micro-

scopes or cameras at a time.”

Seen under a scanning electron

microscope, the new metasurfaces

resemble a cut forest where only the

stumps remain. Each silicon stump, or

pillar, has an elliptical cross-section,

and by carefully varying the diameters

Modustri,

Grand Rapids, Mich.,

entered into a strategic alliance

with

Caterpillar Inc.

(Cat), Peo-

ria, Ill. The companies will work

together to enhance the abilities of

Cat’s customers to measure wear

on parts in new ways, potential-

ly saving hundreds of hours and

millions of dollars in maintenance

expenses.

modustri.com.

BRIEFS

Nordson Corp.,

Westlake, Ohio, acquired

MatriX Technologies GmbH,

Munich, a manufacturer of automated x-ray inspection equipment used

to ensure the quality of electronic printed circuit boards, critical electron-

ic devices, and fully assembled products in consumer, automotive, and

other industrial markets.

nordson.com.