ADVANCED MATERIALS & PROCESSES •

OCTOBER 2014

22

ple structures to be sampled on a wafer. In a probe station

chamber, test structures can be tens of microns in size

(such as for the high-speed pHEMT device measurement

application described later in this article) or up to tens of

millimeters in size for measuring Hall structures.

Measuring devices in the vacuum chamber of a probe

station offer advantages as well. The variability in meas-

urements caused by humidity, condensation, and other en-

vironmental factors can be eliminated. Electronic

properties of some materials, such as organic semiconduc-

tors, can be significantly affected by surface contamina-

tion, and when measured under ambient conditions,

electrochemical leakage currents can obscure sensitive

current measurements. However, once the device is evac-

uated in a probe station, measurement conditions can be

restored. Additional options are available in cryogenic

probe stations for materials and devices where surface con-

tamination must be avoided. For example, high-vacuum

options are used to reduce the base pressure in the cham-

ber; in the advanced stations, the sample stage can be

maintained near room temperature during cool down of

the radiation shields so that residual gases are cryopumped

away from the sample space.

Also, when used in conjunction with sophisticated mo-

bility spectrum analysis software tools, vertical magnetic

field probe stations can be valuable for studying multilayer

or multi-carrier semiconductor Hall samples (such as mul-

tiply doped materials and heterostructures) by segregating

the mobility spectrum for each carrier species. By identi-

fying individual carriers, users can verify doping effective-

ness, correct for unwanted impurities during growth, and

control quality during various manufacturing stages.

Case study: Cryogenic probing

identifies off-state breakdown

Off-state breakdowns in

pseudomorphic high-electron-

mobility transistor

(pHEMT) devices result from the com-

plex interplay of material properties and device geometry.

Because gate-drain breakdown limits the maximum power

handling capability of these devices, this effect has been a

topic of interest since the inception of pHEMT device ar-

chitectures. Several physical mechanisms for the break-

down have been proposed and each has distinct

temperature dependencies that can be used to discern the

dominant mechanism in a given device architecture. Vari-

able temperature, on-wafer, transport measurements were

performed on a commercially available GaAs pHEMT

used in RF applications.

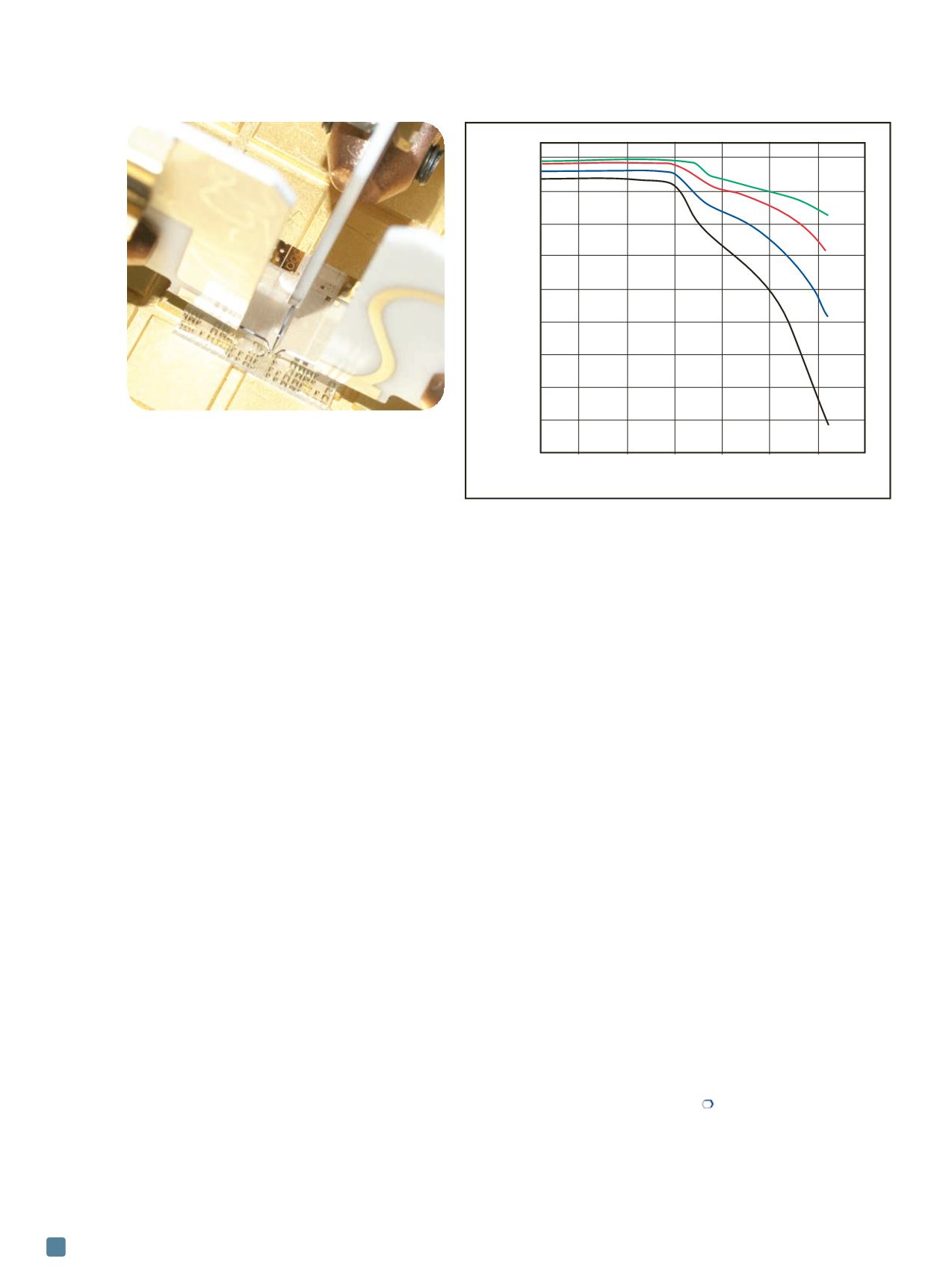

Three distinct gate leakage regimes are identified in the

temperature-dependent gate current for fixed source-gate

voltages in Fig. 3. Above 210 K, the nonmonotonic tem-

perature dependence of the gate current is indicative of a

thermionic field emission mechanism. Below 150 K, the

gate current is independent of temperature with a source-

gate voltage dependence, which suggests the barrier con-

duction is dominated by tunneling transport. Between 150

and 210 K, the observed temperature dependence of the

gate current indicates an intermediate breakdown mecha-

nism, perhaps defect-assisted tunneling.

Conclusion

Semiconductor research is becoming increasingly im-

portant to the development of higher-performing electron-

ics and computing technologies. Terahertz spectroscopy

bypasses the limitations of other characterization tech-

niques by enabling nondestructive measurement under

variable temperature and high magnetic field conditions. It

is in these environments that researchers can learn the

most about novel materials.

For more information:

Andy Phillips is marketing manager,

Lake Shore Cryotronics Inc., 575 McCorkle Blvd., Westerville,

OH 43082, 614.891.2243,

andy.phillips@lakeshore.com,

lakeshore.com.

Fig. 3

—

Three-terminal DC probing configuration for

transistor measurements.

Fig. 4

—

Temperature-dependent pHEMT gate current

during measurement of transfer curves (V

DS

= 3 V).

I Gate , A

V

GS

= -1.0 V

V

GS

= -1.5 V

V

GS

= -2.0 V

V

GS

= -2.5 V

50

100 150 200 250 300 350

Temperature, K

0.0

-20.On

-40.0n

-60.On

-80.On

-100.On

-120.On

-140.On

-160.On

-180.On