ADVANCED MATERIALS & PROCESSES •

OCTOBER 2014

19

ulus initially decreased nearly linearly and then exhibited a

rapid drop beyond 573 K (300°C) due to the creep of grain

boundary phases. Because the target application for these

thermoelectric materials is waste heat recovery, detection

of the onset temperature of grain boundary sliding can help

determine the safe operating temperature range, which in

this case is up to 300°C.

Another example of applying RUS in materials re-

search is shown in Fig. 5, where Young’s modulus is

again measured as a function of temperature

[12]

. In con-

trast to seeing a downward trend as shown in Fig. 4b, an

upward trend is observed in the Young’s modulus of a

different PbTe-based thermoelectric material. The turn-

ing point around 523 K (250°C) in the curve indicates a

change in bonding strength. Further analysis confirms

the change is likely due to an order-disorder phase

transformation: This transformation is controlled by the

diffusion of doping elements such that when the heat-

ing/cooling rate is high, a hysteresis occurs (Fig. 5a),

while no hysteresis is observed when the heating/cool-

ing rate is reduced (Fig. 5b).

Resonant ultrasound spectroscopy

industrial applications

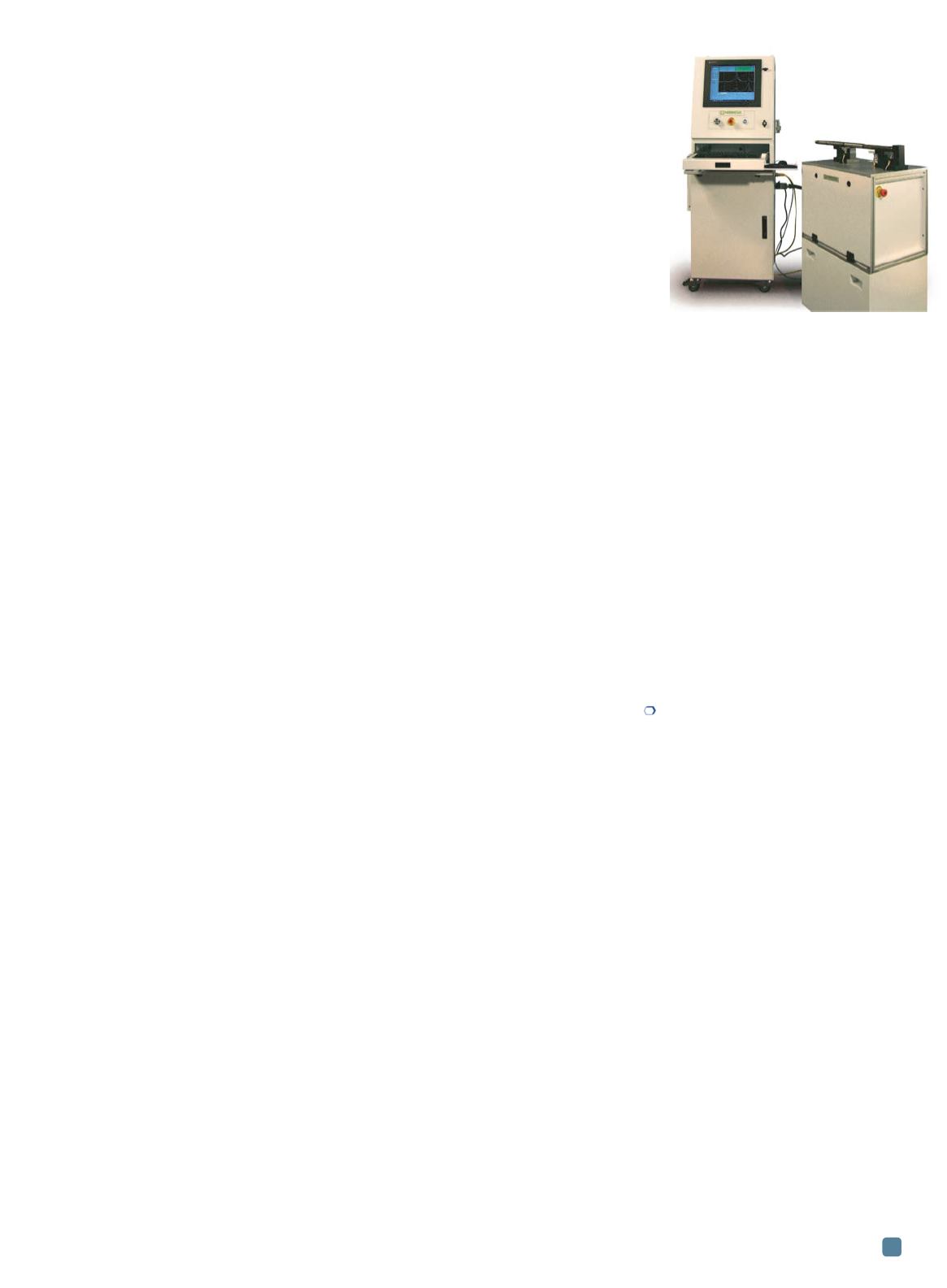

In contrast to research uses of RUS that mainly focus

on material property measurements, industrial applica-

tions primarily reside in nondestructive evaluation (NDE)

of precision components. The basic configuration of an in-

dustrial RUS unit is similar to its research counterpart, al-

though the sample stage and transducers may be modified

to accommodate larger and more complicated parts. Figure

6 shows an example of a commercial RUS unit with inte-

grated testing and online analysis capabilities.

A major difference between industrial and research ap-

plications involves data usage. Instead of calculating the

elastic constants, measured ultrasonic spectra (Fig. 2) are

directly used as input for analysis. Defects that result in

variations in vibrational modes (eigenfrequencies) will lead

to changes in RUS spectra. By comparing measured spec-

tra with standards, it can be determined whether a part

should be accepted or rejected, and potential defects in the

bad parts can be explored.

A general guideline for using RUS to evaluate the in-

tegrity of metallic and nonmetallic (i.e., ceramics and

composites) components is provided in ASTM standard

E2001-98

[13]

. According to this standard, a

fingerprint

—

usually a few characteristic resonant peaks—must first be

established. Then, sorting criteria for acceptance/rejec-

tion should be determined. In practice, establishment of

sorting criteria is often realized by examining a large

number of good and bad parts and analyzing the data in

a statistical manner. Typical criteria include the follow-

ing aspects in measured spectra:

peak shifts,

or changes in

peak positions;

peak splitting,

where a single peak splits

into two or more due to symmetry imperfection; and a

combination of peak shifts and splitting. Other consider-

ations include changes in peak amplitudes, peak broaden-

ing, and phase changes

[14]

.

Summary

Successful RUS applications

include identifying various

types of defects including

cracks (on the order of millime-

ters or submillimeters), cavi-

ties, geometrical imperfections,

compositional inhomogeneity,

and hardness variations

[13,14]

.

Compared to traditional NDE

methods, such as dye penetra-

tion, magnetic particle method, and

eddy current testing, RUS possesses

some unique advantages. One is the

ability to examine parts with both external and internal de-

fects, compared to dye penetration and magnetic particle

methods that can only be used to detect external defects.

Another is the ability of RUS to evaluate both conducting

and nonconducting components; in contrast, the eddy cur-

rent method does not work with nonconducting materi-

als. In addition, RUS measurements can be made very

quickly (on the order of minutes or less) if a good testing

procedure is developed.

Nevertheless, RUS has drawbacks. For example, it re-

quires special equipment and software, which are not yet

widely available. Further, establishing sorting criteria often

involves extensive efforts in terms of testing and data

analysis. Because it is an emerging technology, the learning

curve for adapting RUS to existing industrial facilities may

be steep. However, once these initial obstacles are cleared,

RUS will serve as a fast and reliable NDE technique in

many manufacturing settings.

For more information:

Fei Ren is an assistant professor, de-

partment of mechanical engineering, Temple University, 1801

N. Broad St., Philadelphia, PA 19122, 215.204.9593,

renfei@temple.edu.

References

1. D.B. Frasier and R.C. LeCraw,

Rev. Sci. Instrum.,

Vol 35,

p 1113, 1964.

2. H. Schreiber, et al.,

Science,

Vol 167, p 732, 1970.

3. A. Migliori, et al.,

Phys. Rev. B,

Vol 41, p 2098, 1990.

4. J. Maynard,

Phys. Today,

Vol 49, p 26, 1996.

5. Quatrosonics was renamed Quasar International in 2000,

and is now part of Illinois Tool Works’ Magnaflux Division,

see Ref. 6.

6. Quasar PCRI, Magnaflux, Albuquerque, NM.

7. Dynamic Resonance Systems Inc., Powell, WY.

8. A. Migliori, J.L. Sarrao, and W.M. Visscher,

Physica B,

Vol

183, p 1, 1993.

9. A. Migliori and J.L. Sarrao,

Resonant Ultrasound Spec-

troscopy,

Wiley-VCH, New York, 1997.

10. F. Ren, et al.,

Philos. Mag.,

Vol 89, p 1163, 2009.

11. F. Ren, et al.,

Mater. Res. Soc. Symp. Proc.

, Vol 1044, p 121,

2008.

12. F. Ren, et al.,

Acta Mater.

, Vol 58, p 31, 2010.

13. ASTM E 2001 – 98, Standard Guide for Resonant Ultra-

sound Spectroscopy for Defect Detection in Both Metallic and

Non-metallic Parts, ASTM, West Conshohocken, PA, 1999.

14. F. Willis, in

Proceedings of the Resonance Meeting,

Vol 1,

p 23, 2001.

Fig. 6

—

Commercial RUS unit.

Courtesy of Magnaflux.