ADVANCED MATERIALS & PROCESSES •

OCTOBER 2014

17

Resonant Ultrasound Spectroscopy

Offers Unique Advantages as a

Nondestructive Test Method

R

esonant ultrasound spectroscopy

(RUS) is an emerging ultrasonic meas-

urement technique. By measuring the

natural vibrational frequencies of test samples,

RUS can determine the full set of elastic con-

stants. For example, RUS can obtain Young’s

modulus, shear modulus, and Poisson’s ratio

for isotropic materials. By comparing the vi-

brational spectra of a test sample to those ob-

tained from a standard, it is possible to infer

the causes of the differences (if any) and de-

tect various part defects, such as size varia-

tions, cracks, and pores.

RUS first appeared in the second half of

the 20th century with its development fueled

by advances in computing power. In 1964,

Frasier and LeCraw performed one of the ear-

liest RUS measurements on spheres of

isotropic materials

[1]

. After this initial success,

much improvement was made in the geo-

physics community, where RUS was used by

Anderson and coworkers to measure the elas-

tic properties of spherical lunar samples in the

1970s

[2]

. After the late 1980s, RUS was adapted

by some physicists and materials scientists in-

cluding Migliori and coworkers, who began to

examine high-temperature superconducting

materials

[3]

. Current research uses of RUS in-

clude a wide range of topics in physics, geo-

physics, and materials science, where elastic

constants are being accurately measured on

samples as small as 70 µg

[4]

.

Industrial applications of RUS appeared

around the beginning of the new millennium,

used for quality control of manufactured parts.

Among the first commercial RUS units in the

U.S. were those made by Quatrosonics

[5]

in the

1990s based on technology developed at Los

Alamos National Laboratory. However, due to

the hardware and software complexity, com-

mercial RUS units are still only available from a

few sources

[6,7]

.

RUS is attractive because measurements are

fast and nondestructive, and can also be auto-

mated. But data interpretation could be chal-

lenging due to the complicated nature of the

theories. Thanks to advances in computer sci-

ence and technology, codes and software are

now available for data reduction and analysis,

as well as interpretation.

Resonant ultrasound spectroscopy

fundamentals

All RUS-related applications start with

measuring the vibrational response of test sam-

ples when subjected to mechanical stimulation.

For a piece of solid material, the natural me-

chanical vibrational frequencies (i.e., eigenfre-

quencies), which correspond to specific

vibrational modes such as bending and torsion,

are solely determined by the material’s mass

density, geometric parameters, and elastic con-

stants. Because mass density and geometric

factors are easy to obtain, if one could measure

the natural vibrational frequencies of a test

sample, its elastic constants could be back cal-

culated—an inverse mathematical problem. In

practice, due to the constraints of computing

power, some simple geometry (such as spheres,

cubes, and prismatic bars) is often used in ac-

tual measurements.

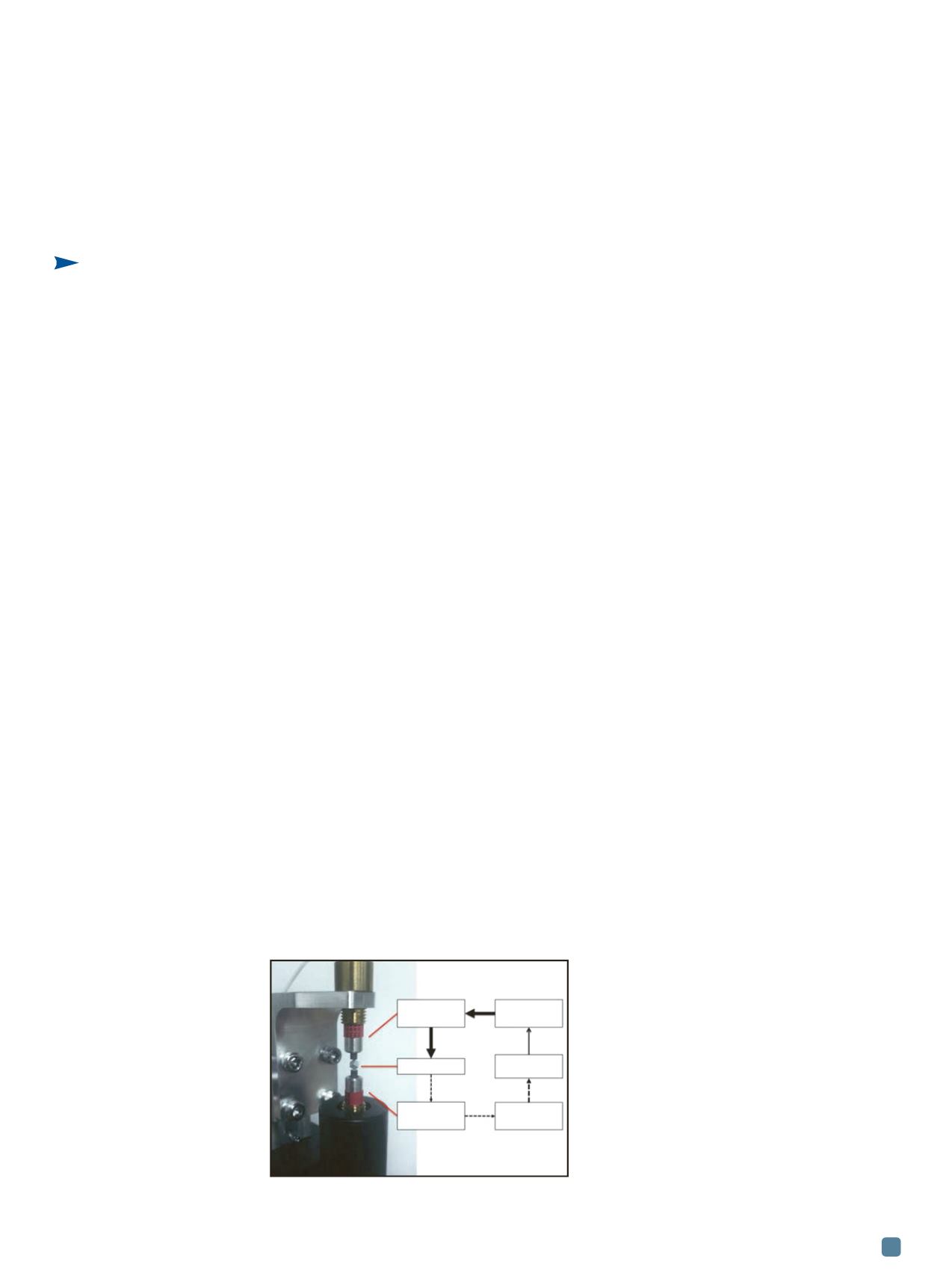

An example of measuring a cube sample

using a two-probe RUS is shown in Fig. 1. The

sample, approximately 2 mm wide on each

side, is sandwiched between two piezoelectric

transducers. One of the transducers (the

driver transducer) is used to apply mechanical

stimulation provided by a signal generator to

the test sample; the other transducer (the

pickup transducer)

listens

to the response

from the sample and feeds it back to the data

acquisition module. Input signals are usually

a series of mechanical waves with a wide band

of frequencies in the ultrasonic range (a few

hundred kHz to MHz). Only those waves with

frequencies matching the natural vibrational

frequencies of the test sample can be detected

by the pickup transducer. The resulting spec-

Haoqi Li

Fei Ren*

Temple University

Philadelphia

Resonant

ultrasound

spectroscopy

is making

headway as a

fast and

nondestructive

measurement

technique.

Thanks to

advances in

computer

technology,

codes and

software are

now available

for data

reduction,

analysis, and

interpretation.

*Member of

ASM International

Fig. 1

—

Typical resonant ultrasound spectroscopy

(RUS) measurement in a two-transducer setup.

Driver

transducer

Sample

Pickup

transducer

Signal

generator

Computer

Amplifier