news

industry

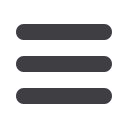

Shrinking plastic closes nanowire gap

Engineers at the University of Illinois at Ur-

bana-Champaign are using Shrinky Dinks—plastic

that shrinks under high heat—to close the gap be-

tween nano-wires in an array to make them useful

for high-performance electronics applications.

Nanowires are placed on the Shrinky Dinks plastic

just like any other substrate, and then shrunk to

bring the wires much closer together. This enables

creation of very dense arrays of nano-wires in a

simple, flexible, and controllable process. The new

method also brings the nanowires into alignment

as they increase in density. Wires even more than

30° off-kilter can be brought into perfect alignment

with their neighbors after shrinking.

For more information: SungWoo Nam, 217.300.0267,

swnam@illinois.edu,

illinois.edu.

Graphene ribbons: Size matters

Using graphene ribbons of unimaginably

small widths—just several atoms across—a

group of researchers at the University of Wis-

consin-Milwaukee (UWM) found a novel way

to “tune” the wonder material, causing the ex-

tremely efficient conductor of electricity to act

as a semiconductor. In principle, their method

for producing these narrow ribbons and manip-

ulating the ribbons’ electrical conductivity

could be used to produce nanodevices.

“Nano-ribbons are model systems for studying nanoscale effects in graphene, but obtain-

ing a ribbon width below 10 nm and characterizing its electronic state is quite challenging,”

says postdoctoral researcher, Yaoyi Li. By imaging the ribbons with scanning tunneling mi-

croscopy, researchers confirmed hownarrow the ribbonwidthmust be to alter graphene’s elec-

trical properties, making it more tunable.

“We found the transition happens at three nanometers and the changes are abrupt,”

says Lian Li.

For more information: Lian Li, 414.229.5108,

lianli@uwm.edu,

uwm.edu.

Mythical boron buckyball does exist

Researchers from Brown University, Providence, R.I., as well as Shanxi University and

Tsinghua University, China, have shown that a cluster of 40 boron atoms forms a hollowmo-

lecular cage similar to a carbon buckyball. It is said to be the first experimental evidence that

a boron cage structure—previously only a matter of speculation—does indeed exist.

Chemistry professor Lai-Sheng Wang and his research group showed earlier this year

that clusters of 36 boron atoms form one-atom-thick disks, which might be stitched to-

gether to form an analog to graphene, dubbed borospherene. Boron clusters with 40 atoms

are also abnormally stable compared to other boron clusters. Figuring out what that 40-

atom cluster actually looks like required a combination of experimental work and model-

ing using high-powered supercomputers.The borospherene molecule is not quite as

spherical as its carbon cousin. Rather than a series of five- and six-membered rings formed

by carbon, borospherene consists of 48 triangles, four seven-sided rings, and two six-mem-

bered rings. Several atoms stick out, making the surface of borospherene somewhat less

smooth than a buckyball.

For more information: Lai-Sheng Wang, 401.863.3389,

lai-sheng_wang@brown.edu,

brown.edu.

Researchers show that clusters of 40 boron atoms form a molecular cage similar to

the carbon buckyball. Courtesy of Wang lab/Brown University.

ADVANCED MATERIALS & PROCESSES •

OCTOBER 2014

16

N

ANOTECHNOLOGY

briefs

Scientists at

AMBER,

a materials

science center based at

Trinity

College Dublin,

Ireland,

discovered a new material that

could revolutionize information

technology, computer processes,

and data storage. The research

group led by Michael Coey created

a new alloy of manganese,

ruthenium, and gallium, known as

MRG. The alloy is a strange new

magnet—internally it is as

magnetic as the strongest magnets

available, but from the outside it

does not appear magnetic. The

material (technically known as a

zero-moment half metal)

will

initiate a completely new line of

materials research and could open

up numerous possibilities for

electronics and information

technology.

www.tcd.ie.

Applied Materials Inc.,

Santa

Clara, Calif., announced two new

systems to help solve critical

challenges in manufacturing high-

performance, power-efficient 3D

devices. The Applied Reflexion LK

Prime CMP system provides

superior wafer polishing

performance with nanometer-level

precision for FinFET and 3D NAND

applications. The Applied Producer

XP Precision CVD system solves

demanding, fundamental

deposition challenges presented by

vertical 3D NAND architectures.

These new CMP (chemical

mechanical planarization) and CVD

(chemical vapor deposition) tools

directly address precision,

materials, and defect issues,

enabling 3D designs to reach high-

volume manufacturing.

appliedmaterials.com.

Plastic is clamped so it only shrinks in one

direction. Courtesy of SungWoo Nam.

Yaoyi Li (foreground) and Mingxing Chen

display an image of a ribbon of graphene

1 nm wide. Atoms are visible as bumps.