news

industry

New process holds promise for Li-ion battery performance

The steadily growing Li-ion

battery market continues its quest

for increased battery capacity

while maintaining a long recharg-

ing process. Structuring materials

for electrodes at the nanometer

length scale is an effective way

to meet this demand; however,

such nanomaterials need to be

produced by high-throughput pro-

cessing to transfer these technolo-

gies to industry.

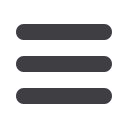

A new approach by researchers

at the National Institute for Mate-

rials Science, Japan, shows poten-

tial for producing nanosized,

composite silicon-based powders

for the negative electrodes within

high-density Li-ion batteries. Re-

searchers successfully produced nanocomposite SiO powders by plasma spray physical

vapor deposition using low-cost metallurgical grade powders at high throughput. Using

this method, they demonstrated a noticeable improvement in battery capacity cycle per-

formance.

www.nims.go.jp/eng.Joining forces to protect Chicago’s electric grid

ComEd, a unit of Exelon Corp., Chicago, will develop a deploy-

ment plan for American Superconductor’s (AMSC), Devens,

Mass., high-temperature superconductor technology to build a

system to strengthen Chicago’s electric grid. The resilient electric

grid (REG) effort is part of the U.S. Department of Homeland Se-

curity (DHS) Science and Technology Directorate’s work to secure

the nation’s electric power grids and improve resiliency against ex-

treme weather, acts of terrorism, or other catastrophic events.

The REG is a self-healing system that provides resiliency in

the event of any grid loss. Installation would be the first commer-

cial application of this advanced technology in the U.S. “We be-

lieve that this system has the potential to play a significant role in

protecting the infrastructure assets so vital to our electrical sys-

tems. Together with the leadership from DHS and ComEd, we

believe AMSC is now in a position to offer this system solution

to cities in America and around the world,” says AMSC president

and CEO Daniel P. McGahn.

comed.com,

amsc.com.

ADVANCED MATERIALS & PROCESSES •

OCTOBER 2014

14

E

NERGY

T

RENDS

briefs

The U.S. Department of Energy

selected a

University of Alabama

startup company for a $1.5 million

award to refine an alternative

material to extract uranium from

the ocean. The company is

developing an adsorbent,

biodegradable material made from

chitin, a compound found in

shrimp shells, other crustaceans,

and insects. Researchers

developed transparent sheets, or

mats, comprised of tiny chitin

fibers, modified for the task. When

suspended beneath the ocean’s

surface, the mats are designed to

withdraw uranium. “Once you put

it in the ocean, it will attract

uranium like a magnet, and

uranium will stick to it,” says one

researcher.

ua.edu.

Alphabet Energy,

Hayward, Calif.,

plans to sell a new type of material

that can turn heat into electricity.

Unlike previous thermoelectrics,

the new material is plentiful,

inexpensive, and nontoxic. The

company is using tetrahedrite—an

abundant, naturally occurring

mineral that is also more efficient

on average than existing

thermoelectric materials.

According to data released by

Alphabet Energy, tetrahedrite costs

about $4 per kg, whereas other

thermoelectric materials cost

between $24 and $146 per kg. The

company is focusing on standalone

generators but is also working with

automotive companies to see if

tetrahedrite can harness heat from

car exhaust.

alphabetenergy.com.

High-resolution transmission electron microscopy

images of the PS-PVD Si core and SiOx shell

composites processed (a) without and (b) with a

1.1 slm methane (CH

4

) gas addition.

The resilient electric

grid is a self-healing

technology that

quickly recovers in the

event that portions of

Chicago’s energy grid

are lost for any reason.

In a small lab at the

SLAC National Accelerator Laboratory,

a team of scientists from the

Stanford

Institute for Materials and Energy Sciences (SIMES),

Calif., is making and testing new types of lithium-

ion batteries. Their goal: Create a battery five times better than ones used today. SLAC lab director Yi Cui

believes one key to creating a better battery is making the cathode of sulfur, instead of lithium-cobalt oxide.

The team devised a yolk-shell design in which individual “nanonuggets” of sulfur are enclosed within a

semi-porous shell that allows lithium ions to pass through but blocks the electrolyte. Making the shell

somewhat larger than the nanoparticle allows the sulfur to swell and contract as it absorbs and releases

lithium during charge/discharge cycles without dissolving.

slac.stanford.edu.

Zhi Wei Seh assembles a prototype battery in

SLAC’s energy storage laboratory. Courtesy of SLAC.