tra are peaks at various frequencies as shown in Fig. 2.

The positions of the peaks correspond to the eigenfre-

quencies of the test sample.

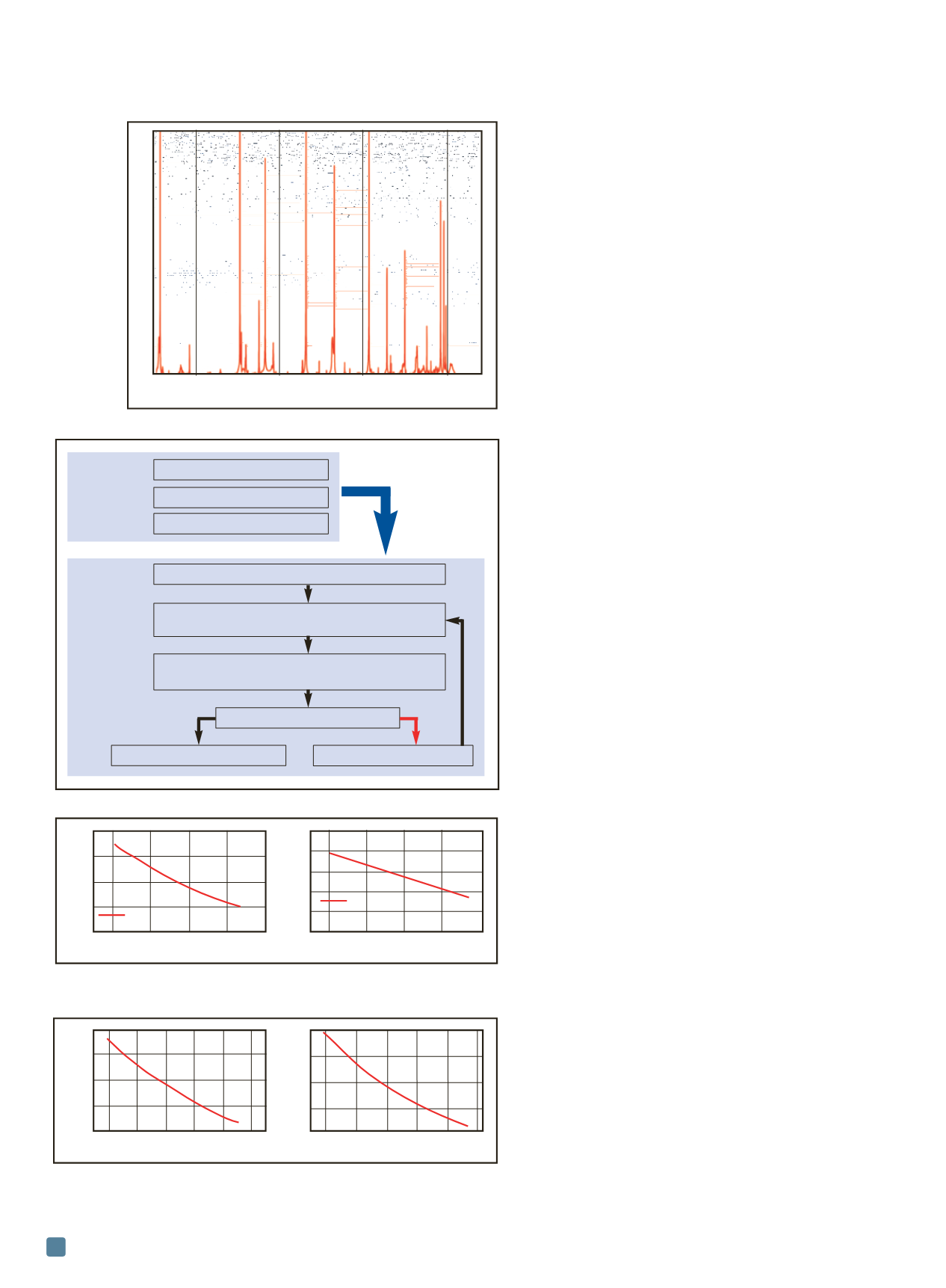

After collecting the resonant frequencies, determining

the elastic constants involves a fairly complicated proce-

dure. Because this is an inverse problem, one must first

provide an initial “guess” regarding the unknown elastic

constants from other means, such as existing knowledge

of similar materials or theoretical modeling. Using these

estimated elastic constants, along with sample geometry

and mass density, the eigenfrequencies of the test sample

can be estimated and compared to the measured data. If

these two sets of frequencies are identical—or the differ-

ence is small enough—then the predicted values can be re-

garded as the sample’s true elastic constants. Otherwise,

the predicted values must be modified and the above steps

repeated. This procedure usually requires a number of it-

erations and is affected by the quality of both the meas-

ured data and initial estimates.

A key step in this data analysis is to find an appropri-

ate algorithm to modify the elastic constants based on dif-

ferences between measured and calculated frequencies.

This is often realized through computer codes and soft-

ware. One common process is the Levenberg-Marquardt

algorithm

[8]

, which is a nonlinear least-squares scheme that

uses Taylor’s expansion to linearize the difference between

measured and calculated frequencies. This data analysis

procedure is illustrated in Fig. 3. RUS theories are ex-

plained further in a textbook by Migliori and Sarrao

[9]

.

Resonant ultrasound spectroscopy

research applications

As previously mentioned, RUS is used to measure the

elastic constants of solid materials in various research areas

including metals, alloys, ceramics, glasses, concretes, and

rocks. Compared to many static testing methods, such as

tensile and bending tests, RUS is nondestructive and can

work with small samples. Compared to other ultrasonic

techniques such as the pulse echo method, RUS features

less preparation and faster sample installation.

Because elastic constants are influenced by other

physical and chemical properties, RUS can be used to ex-

plore many related phenomena, including structural

phase changes, superconducting transitions, magnetic

transitions, and damage accumulation due to micro-

cracking. For example, RUS is used to measure the influ-

ence of porosity on the elastic constants of alumina at

different sintering stages. Young’s modulus as a function

of volume fraction porosity is shown in Fig. 4a

[10]

. This

information can facilitate a deeper understanding of

porosity evolution during sintering and its effect on me-

chanical properties—key aspects in the design and fabri-

cation of engineering ceramics.

Further, RUS measurement can be made under some

extreme conditions such as high and low temperatures.

Figure 4b shows the measurement of Young’s modulus of

a PbTe-based thermoelectric material between room tem-

perature and 673 K (400°C)

[11]

. In this case, Young’s mod-

ADVANCED MATERIALS & PROCESSES •

OCTOBER 2014

18

100

200

300

400

Frequency, kHz

Intensity, a.u.

Fig. 2

—

Sample spectrum obtained from RUS measurement.

Mass density

Geometric parameters

Resonant frequencies

Estimate elastic constants.

Calculate resonant frequencies from mass density,

geometry, and estimated elastic constants.

Determine difference between calculated

frequencies and measured resonant frequencies.

Yes

Is the difference minimized? No

Solution found!

Update elastic constants.

Data

collection

Data

analysis

Fig. 3

—

Schematic of data collection and analysis steps involved in RUS.

Fig. 4

—

RUS is used to determine (a) porosity effect on Young’s modulus

of alumina (after

[10]

), and (b) temperature effect on Young’s modulus of

PbTe-based thermoelectric materials (after

[11]

).

Fig. 5

—

Temperature dependent Young’s modulus as measured by RUS

reveals a diffusion controlled order-disorder phase change: (a) heating/

cooling rate = 5 K/min, (b) heating/cooling rate = 2 K/min

[12]

.

0.05 0.15 0.25 0.35 0.45

Porosity

300 400 500 600 700

Temperature, K

300 400 500 600 700 800

Temperature, K

300 400 500 600 700 800

Temperature, K

Linear trend

60

55

50

45

40

35

52

48

44

40

36

52

48

44

40

36

Young’s modulus, GPa

Young’s modulus, GPa

Young’s modulus, GPa

Young’s modulus, GPa

400

300

200

100

0

Exponential trend

(a) (b)

(a) (b)