ADVANCED MATERIALS & PROCESSES •

JULY 2014

17

formity during a brazing cycle is +/- 5°F (3°C) of set point.

Aluminum brazing has a very narrow window of accept-

able brazing temperatures. The governing rule for alu-

minum brazing is that the filler metal must liquidize before

the base metal reaches its solidus temperature. This tem-

perature difference may be as small as 10°-18°F (5°-10°C).

Figure 5 shows the small process window available for alu-

minum brazing. For example, a base metal 6061 alloy will

have a solidus temperature of 1099°F (593°C) and a liquidus

temperature of 1206°F (652°C). The brazing temperature

range would be 1049°-1085°F (565°-585°C) depending on

the filler metal used.

Using a heating step at a soak temperature just below

the solidus point of the filler metal ensures that all the parts

and joints to be brazed reach the correct temperature at

approximately the same time. At this time, the ramp to

brazing temperature starts, filler metal begins to melt, and

capillary wetting of the braze joints occurs.

The time duration of braze temperature must be kept

to a minimum as melted filler metal is vaporizing in the

deep vacuum while trying to wet the braze joints. Too

much loss of filler metal to vaporization will result in poor

joint wetting and subsequent loss of joint strength and seal-

ing ability. After the brazing temperature soak duration is

complete, an immediate vacuum cooling cycle follows,

which solidifies the filler metal in the braze joints and stops

material vaporization.

The type of precise temperature control and uniformity

needed for VAB is achieved through the use of several

heating control zones around the parts while at the same

time maintaining the surface temperatures of the heating

elements as near to the part temperature as possible. A

large delta in temperature between the heating elements

and the parts would result in overheating of the parts’ sur-

face, possibly above the solidus temperature for the mate-

rial as the filler metal begins to melt.

Braze joint fundamentals

Figures 6 and 7 show typical braze joints used in alu-

minum component construction. In general, the difference

between the favorable and unfavorable types of joints is the

amount of overlapping that results in good braze joints. A

stronger braze joint has a large surface area wetted by the

filler material. Too much overlapping is detrimental to the

joint because the filler material will not cover the entire

surface when it flows into the joint.

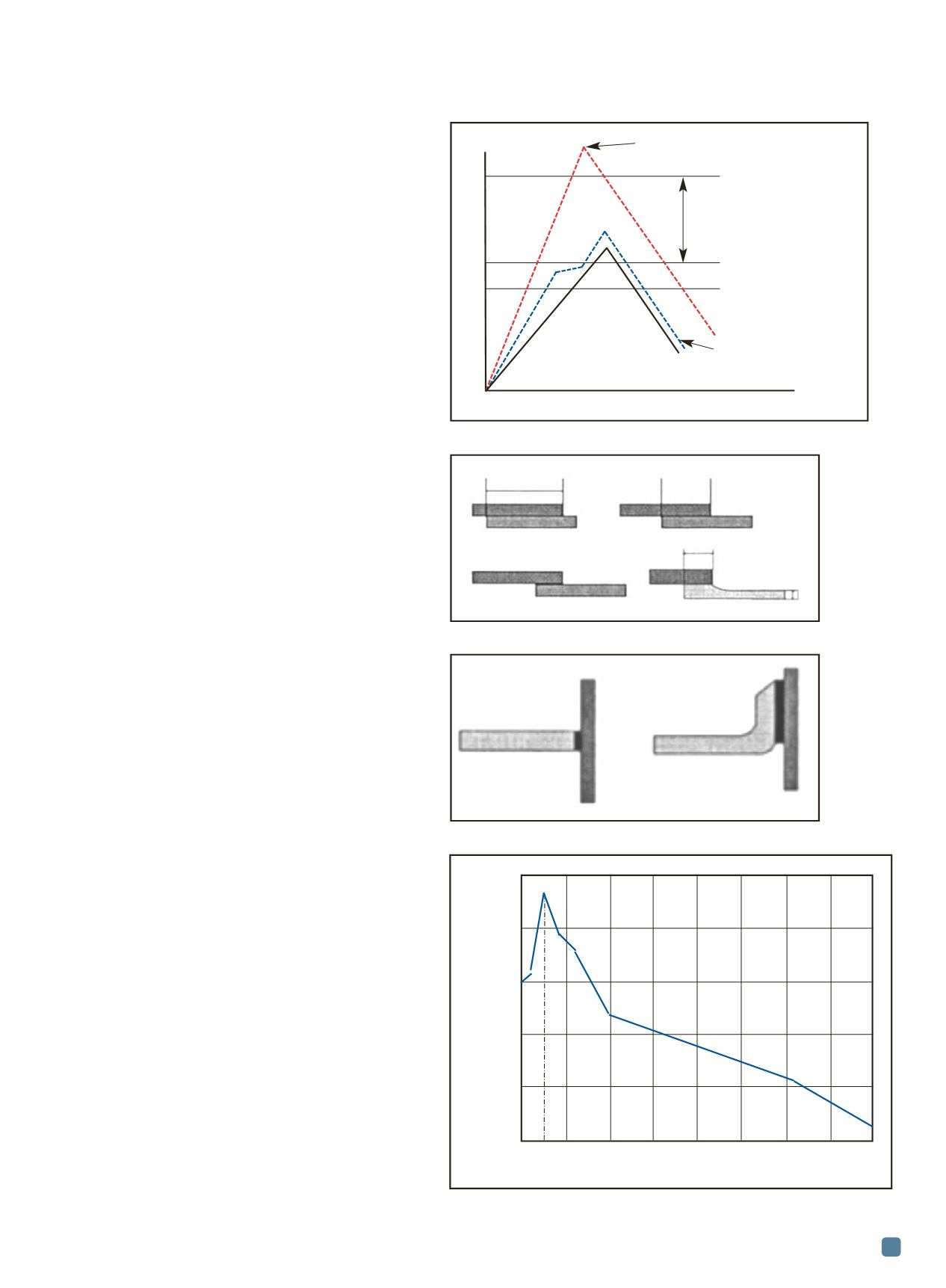

Braze joint strength is dependent on two primary me-

chanical characteristics: Joint wetted surface area and the size

of the gap intowhich the fillermetal flows. In Figs. 6 and 7, im-

proved joint surface area characteristics are shown. Figure 8

illustrates the importance of a proper joint gap.

Gaps between 0.003-0.008 in. (0.08-0.2mm) work best for

vacuum furnace brazing. Joint gaps are controlled by theman-

ufacturing tolerances of the parts to be brazed and by proper

clamping (pre-loading) of the part assemblies to be brazed.

Fixturing and cleaning parts

Part assemblies must be fixtured properly for brazing

Fig. 5 —

Temperature vs. brazing cycle steps.

Fig. 6 —

Lap joints

[2]

.

Fig. 7 —

T joints

[2]

.

Fig. 8 —

Braze joint strength vs. joint gap

[3]

.

Temperature

Time

Poor temperature control

Heat damage occurs

Process

window

Brazing alloy flows

Magnesium vaporization

Pattern that must develop

Unfavorable

Favorable

>6 t

3-6 t

t

t

4 t

Unfavorable

Favorable

0.003 0.006 0.009 0.12 0.15 0.18 0.21 0.24

Joint thickness, in.

Tensile strength, psi

140,000

120,000

100,000

80,000

60,000

40,000