powder (C) was atomized in air. Particle morphology and

size distribution are important considerations in develop-

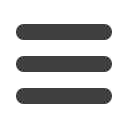

ing EBM process parameters. Figure 1a shows two distri-

butions for powder A—one separating the satellite

particles from the distribution measurement, and one in-

cluding them in the overall particle diameter. Powder B has

a skewed distribution with small particles, while powder

C shows a bimodal distribution with an average size of

roughly 55 µm. Particles that are too large are not de-

posited by the raking system, while those that are too small

may be charged and scattered by the beam and may also

require special handling and storage considerations. The

relative packing density, as well as the contact area between

particles, can have a significant influence on flowability,

thermal conductivity, and melt pool liquid flow. Apparent

density and volumetric flow rate of the three high-purity

copper powder types, shown in Fig. 1b, were analyzed ac-

cording to ASTM standards B703-10 and B855-06, respec-

tively

[14,15]

. An Arnold meter consistently measured equal

volumes of powder. Flow time (in seconds) of the sample

was then measured using a calibrated Hall flowmeter.

Subsequent microscopic analysis explains some of the

differences in flow times and apparent densities for the dif-

ferent powders. Powder A particles, shown in Fig. 1c, are

irregularly shaped and exhibit a higher flow time than

powder B and C particles, which are nearly spherical. For

particles of relatively equal size, improved flow tends to

come at the cost of reduced packing. For all powder types,

another cause of poor flow characteristics involves small

satellite particles attached to the surface of larger ones.

Microstructural and elemental powder analysis

All powder samples were mounted, ground, polished

(0.03 μm alumina), and etched using a solution of 100 mL

water, 8 mL sulfuric acid, 4 mL sodium chloride, and 2 g

potassium perchlorate. For imaging, a Reichart MF4 A/M

optical metallograph with digital image converter was

used. Polished and etched samples were also observed in a

Hitachi H-8500 field emission SEM. Residual Vickers mi-

croindentation hardness values were measured in a Struers

Doramin A-300 digital test station.

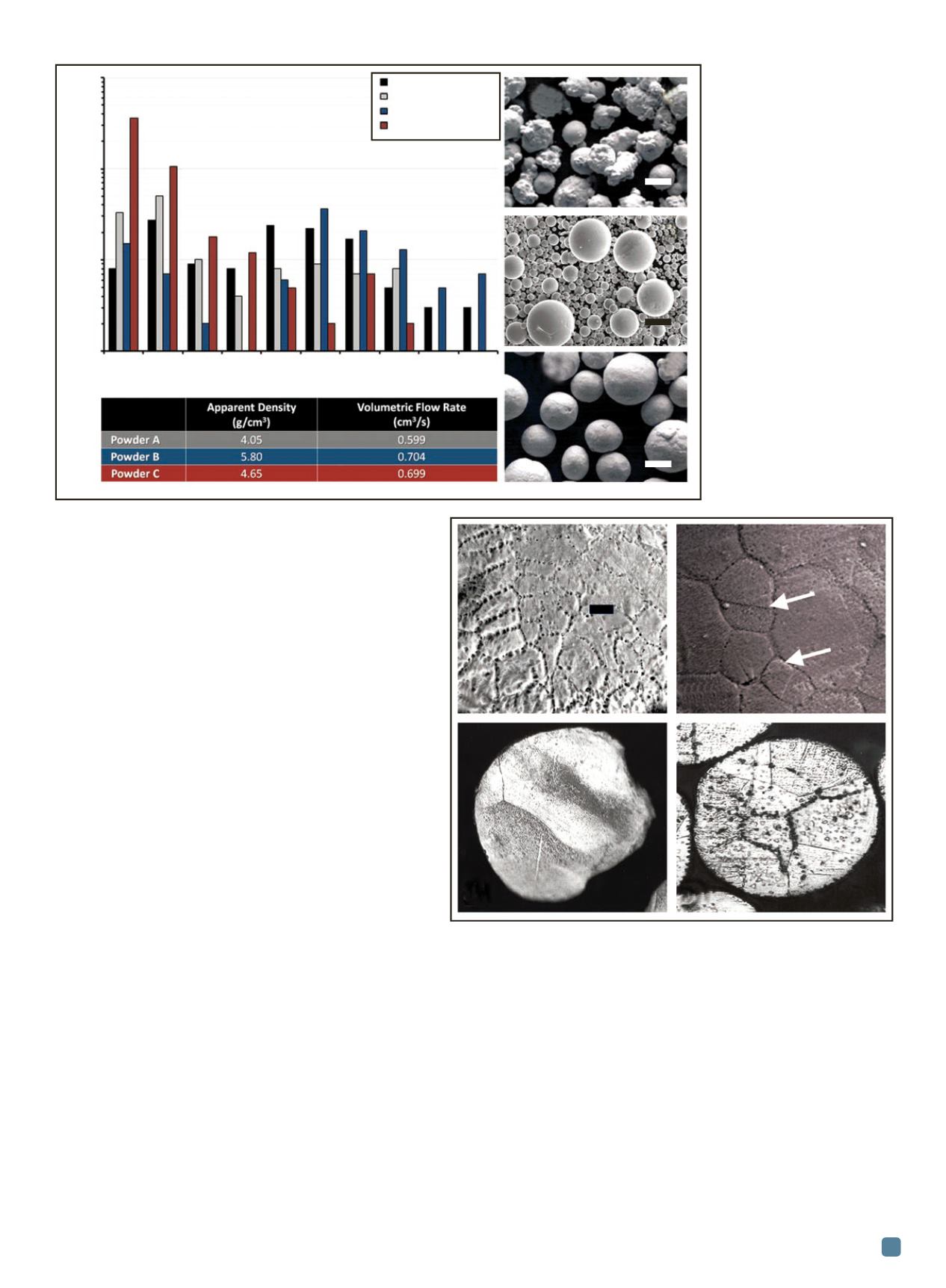

Oxygen content in the powder plays a significant role

in the EBM process. The three powders were analyzed for

oxides and it was found that powders A and C had the

greatest concentration due to the manufacturing processes

used. Figure 2a shows an SEM image of a cross-section for

a powder C particle with small equiaxed grains with no-

ADVANCED MATERIALS & PROCESSES •

JULY 2014

21

Fig. 1

—

Measurements of

particle size distribution for

each powder type (1a).

Table defines average

apparent density and average

volumetric flow time (1b).

Micrographs show shapes of

three different powder

types—powder A (1c),

powder B (1d), and powder

C (1e).

Fig. 2

—

Magnified SEM image of powder C section showing high

concentration of oxides at the grain boundaries (a), and powder B section

showing some oxides at the grain boundaries indicated by arrows (b).

Optical microscopy views of embedded, polished, and etched Cu particles of

powder B, new (c) and used after several EBM build cycles (d), showing a

nearly equiaxed grain structure with increased oxygen in the grain boundaries.

(a)

(b)

(c)

(d)

(e)

1000

100

10

1

Particle count

1-10 11-20 21-30 31-40 41-50 51-60 61-70 71-80 81-90 91-100

Particle size, µm

Particle size distribution

40 µm

40 µm

40 µm

Powder A – Single

Powder A – Bulk

Powder B

Powder C

5 µm

(a) (b)

(c)

(d)