ADVANCED MATERIALS & PROCESSES •

JULY 2014

18

in order to maintain joint gaps, joint alignment, flow pas-

sage alignment, and overall assembly tolerances. Fixturing

materials must be chosen carefully due to different coeffi-

cients of expansion for varying materials. Fixture designs

are also extremely part dependent, thought out in great de-

tail, and are proprietary in some cases because they are an

integral part of the manufacturing process.

Along with proper joint design and fixturing, braz-

ing requires part assemblies to be cleaned properly prior

to assembly then properly handled in order to avoid

contamination prior to brazing. All grease, oil, and par-

ticulates must be cleaned off the parent and filler metal

surfaces, and assemblers must be careful not to transfer

oils from their skin to these surfaces when stacking

parts together. Typical cleaning methods include vapor

degreasing, hydrocarbon wash, aqueous washing, acid

etching, and vacuum de-oiling.

Furnace characteristics

As noted previously, one key process parameter of VAB

is a deep vacuum level and adequate pumping throughput

to keep up with the significant outgassing that takes place

during the heating cycle due to magnesium vaporization.

Typical VAB furnaces include large diffusion pumps and

backing pumps to accomplish these requirements. Figure

9 shows typical pumping arrangements for these furnaces.

The pumping capacity required for a given aluminum

brazing furnace depends on the load, specifically the load

surface area being brazed. The larger the load surface area,

the larger the required pumping capacity. Due to the fact

that most of the magnesium vaporization occurs in the

10

-4

to 10

-5

torr range, diffusion pump(s) must handle the

gas load during mag burst with adequate backing pumps.

To facilitate vacuum pumping in the furnace, the

cooling jacket around the vacuum vessel runs at higher

than ambient temperatures. This warm wall design helps

prevent water vapor condensation inside the vessel when

the door is open for loading/unloading. Water vapor is

the enemy of aluminum brazing—it slows pumping speed

and breaks down, releasing oxygen into the furnace. The

warm wall design lessens the bonding strength of the

magnesium oxide that forms during brazing and ulti-

mately condenses on the chamber’s inner wall, making it

easier to mechanically clean.

VAB furnaces must maintain a low leak-up rate to

prevent the outside atmosphere from entering the fur-

nace during brazing. Vacuum quality contains a very low

PPM of oxygen throughout the brazing cycle. Good de-

sign practices for vacuum chambers that have a low leak-

up rate typically include minimal use of pipe thread

joints, using a 63 micro-finish or better on sealing sur-

faces for O-rings, and using the correct O-ring material

for the sealing area’s temperature.

Heating elements

Other important process parameters include precise

temperature control and temperature uniformity. Placing

the sensing junctions of thermocouples near the heating

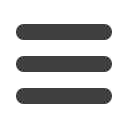

Fig. 9 —

Large diffusion pump on a vacuum aluminum brazing furnace.

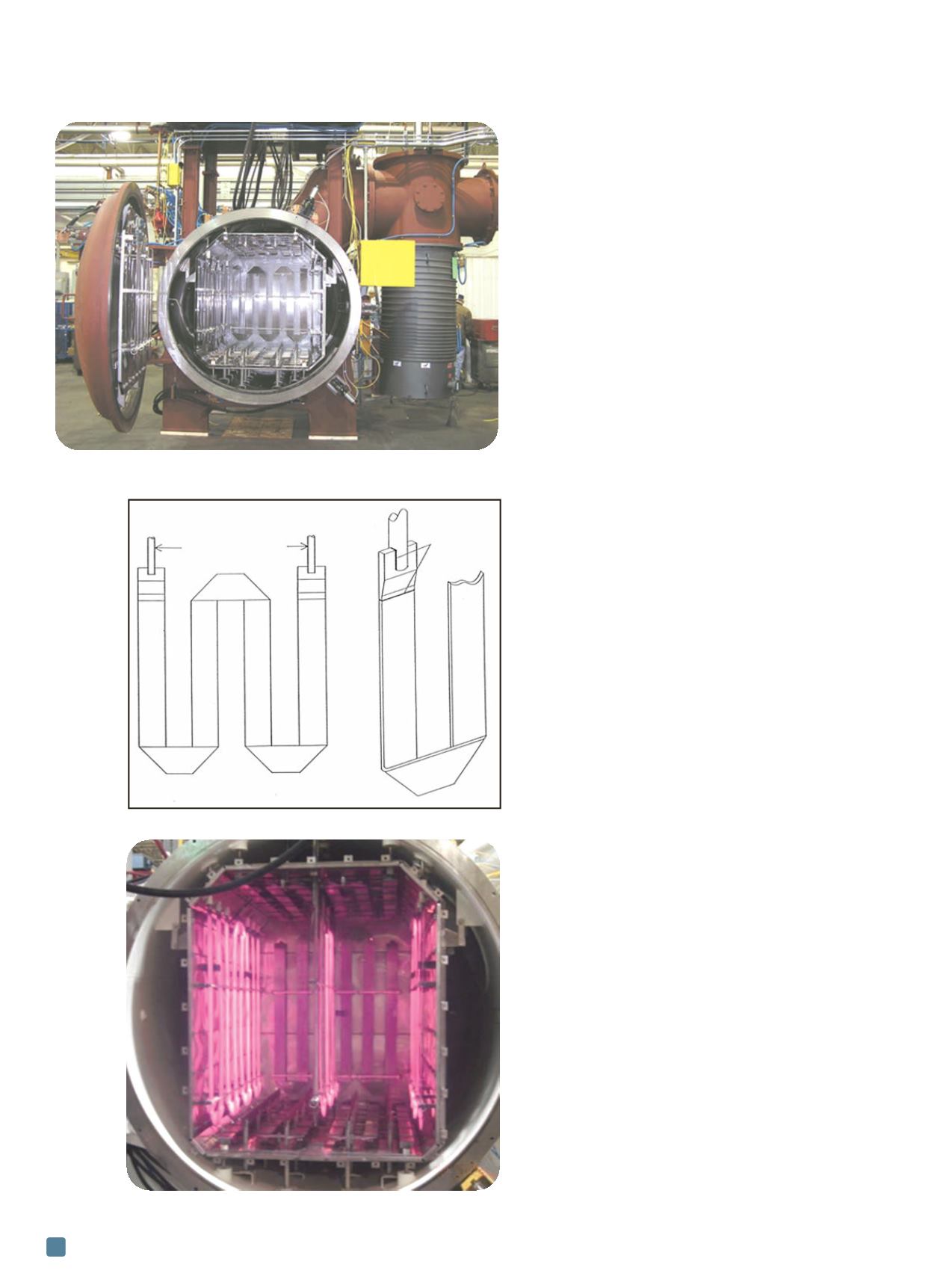

Fig. 10 —

Wide band heating element.

Fig. 11 —

New vacuum aluminum brazing furnace.

Power terminals

Welds