ADVANCED MATERIALS & PROCESSES •

JULY 2014

23

ponent than in Fig. 3b and the part

temperature was considerably

higher, producing a component

with a more conventional Cu

equiaxed grain structure contain-

ing coherent annealing twins. This

structure does not show any direc-

tionally solidified microstructure.

Table 1 shows initial testing re-

sults of the physical properties.

Bulk thermal conductivity

(W/m*k) measurements were

recorded at ambient conditions

using the ThermTest TPS 2500S

thermal constants analyzer

(ISO/DIS 22007-2.2). Electrical

conductivity (% IACS), also carried

out in ambient conditions, was

measured with a Verimet Eddy

current conductivity meter. Tensile

testing was carried out on ASTM

E8 subsize specimens fabricated in

the

XYZ

and

XZY

orientations per

ASTM F2921.

Prototype fabrication

and field testing

The final step in this feasibility

study was to demonstrate the ability to fabricate a complex

geometry that incorporates internal cooling channels. The

block shown in Fig. 4 was fabricated with three different

channel sizes running straight through the part in three or-

thogonal directions that curve through the part with 90°

elbows. This design also demonstrates the ability to clean

sintered powder from internal cooling channels.

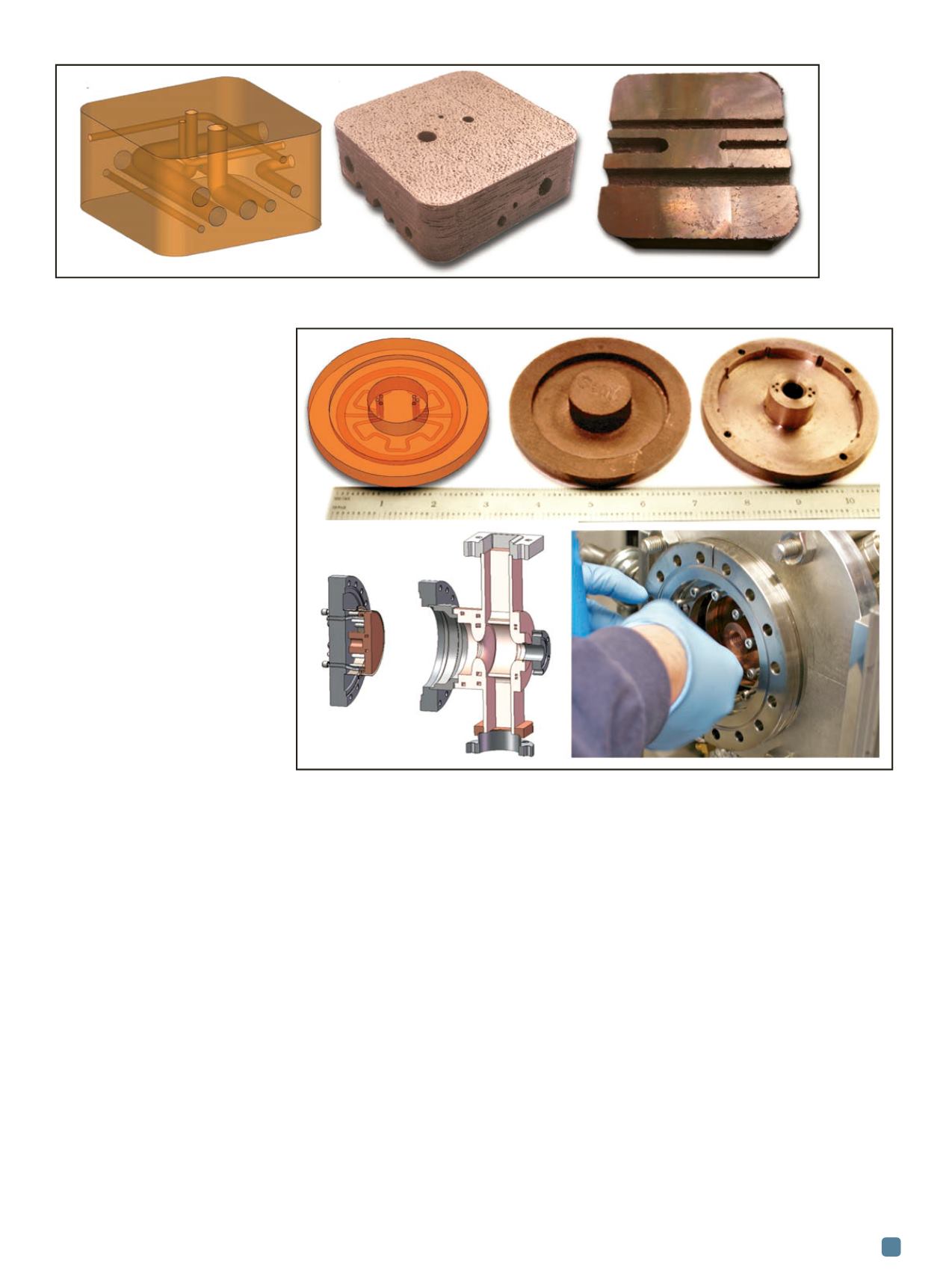

Cathode high power RF testing

In order to verify RF performance of the EBM copper,

a copper cathode suitable for testing in the UCLA Pegasus

1.6 cell photoinjector also was fabricated using the process

parameter sets developed during initial experiments. An

example is shown in Fig. 5. Figure 5 also shows the cathode

in the as-EBM condition, after final machining, and being

installed in the Pegasus photoinjector (Fig. 5e). No other

heat treatment was carried out on the EBM cathode prior

to final machining.

The EBM copper cathode performed as well as other

cathodes conventionally machined from wrought oxygen-

free (OFE) copper material during high power RF testing.

Stable operation with 70 MV/m peak electric fields on the

cathode was achieved after two hours of RF conditioning. A

photoelectron beam with energy of 3.3 MeV and charge of

60 pC was measured, along with a cathode quantum effi-

ciency of ~2x10

-5

. These numbers are consistent (given the

operating gradient) with conventional OFE copper cathodes

measured in the past at the Pegasus Laboratory.

Conclusions

Although the high thermal conductivity of copper

presents challenges for direct AM processes, fully dense

copper components with complex geometries were

demonstrated. Of particular interest is the ability to fabri-

cate internal cooling channels and mesh structures to op-

timize thermal management. In addition to EBM

processing parameters, oxidation of the copper powder

was found to hinder the ability to make completely suc-

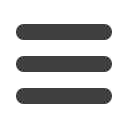

Fig. 4

—

3D CAD model of the cooling channel test block shows internal cooling channel geometry (a); photographs of the

sectioned EBM-fabricated test blocks show cooling channels of 1.5, 4, and 7 mm in diameter (b and c).

Fig. 5

—

CAD rendering shows internal cooling channels of proposed EBM fabricated cathode offered

as a standard drop-in replacement by RadiaBeam (a); photograph of the cathode blank in the as-EBM

condition (b), and after final machining (c); CAD rendering of the RadiaBeam prototype freeform

cathode and freeform photoinjector (d); and installation in the UCLA Pegasus 1.6 cell Photoinjector (e).

(a) (b) (c)

(a) (b) (c)

(d) (e)