ADVANCED MATERIALS & PROCESSES •

JULY 2014

22

table oxide (Cu

2

O) in the grain boundaries and a corre-

sponding SEM image for 99.99% Cu powder B (Fig. 2b)

with a lower density of grain boundary oxides (arrows).

While the atomization and rapid solidification of the pow-

der manufacturing process itself incorporates various

oxide concentrations, residual oxygen and water vapor in

the EBM system is also absorbed in the unconsolidated

powder during processing. This feature is shown in Figs.

2c and 2d, which compare optical metallographic cross-

section views for the initial (precursor) powder B and used

powder particles, showing recognizably increased oxides

at the grain boundaries.

Evident from these figures is that the powder parame-

ters (especially the oxide or oxygen content), combined

with the EBM build parameters, must be carefully consid-

ered in order to fabricate products with desirable proper-

ties, particularly high electrical conductivity.

EBM processing of copper samples

Powder A was selected for further study. Although this

powder exhibited relatively poor raking characteristics due

to its irregular shape, its significantly lower cost made it an

attractive candidate for EBM parameter development.

EBM parameters were assigned to each cylinder based on

a previous feasibility study

[5]

designed to provide a starting

point for subsequent parameter

optimization. The EBM process

was operated in automatic mode,

in which parameters such as beam

current and speed are calculated

for each layer and adjust with

changes in part geometry to main-

tain a stable process. The desired

surface temperature is specified

and a “speed function” is selected.

Both substrate starting tem-

perature and desired surface tem-

perature are critical for the build,

as over-melting or over-sintering

makes powder recovery difficult

or impossible. These tempera-

tures also affect surface quality,

porosity, and microstructure. The

speed function is a parameter

that adjusts beam rate during

hatching, with higher values re-

sulting in higher beam speeds.

Other adjusted parameters in-

clude hatch spacing and contours

functions. An experiment was de-

signed where 24 cylinders in six

builds were fabricated with 24

different sets of process parame-

ters. The goal was to find a set of

process parameters to produce

fully dense copper cylinders with

an acceptable surface finish and

desired microstructure.

Early experiments resulted in cylinders with severe de-

lamination, hypothesized to be caused by a significant

thermal gradient within each layer. The high thermal con-

ductivity of the copper powder (particularly after sinter-

ing/melting) was suspected to be the cause. To balance

heat transfer throughout the build area, three stainless steel

plates (210 × 210 × 10 mm) were installed under the cop-

per start plate. After analyzing all specimens, a parameter

set was developed to consistently produce acceptable parts.

From this theme, samples were prepared for examination

of metallurgical, mechanical, thermal, and electrical prop-

erties. Finally, prototypes of the RF photoinjector were fab-

ricated for field testing.

Sample evaluation

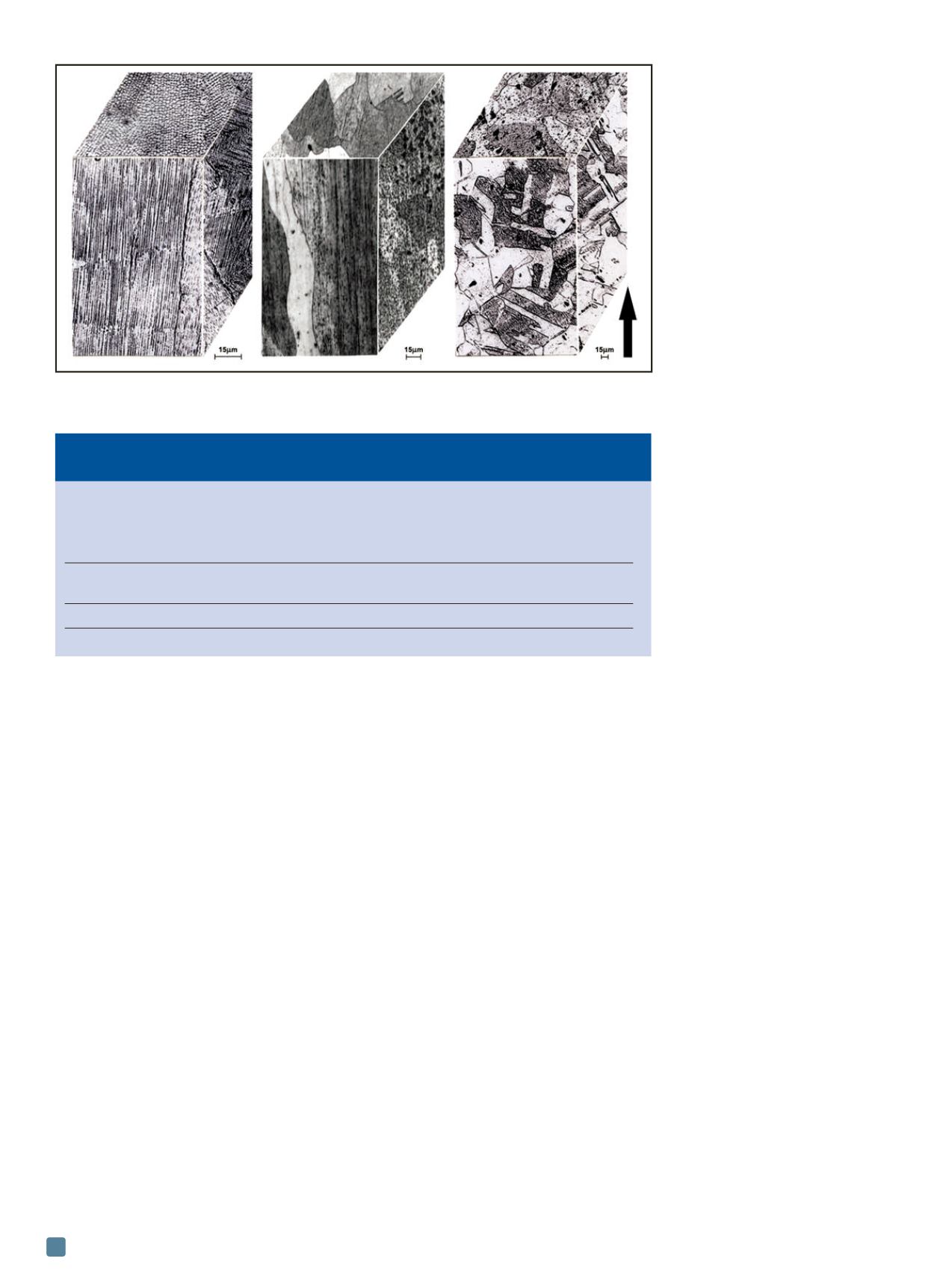

Figure 3 shows corresponding and comparative 3D op-

tical metallographic image composites illustrating oxide

influenced, directionally solidified microstructures or mi-

crostructural architectures. In Fig. 3a, using a mixture of

the high-oxide containing powder C and powder A, EBM

processing produces columnar oxide architectures ori-

ented in the build direction (arrow). In contrast, Fig. 3b

shows columnar grain structures intermixed with colum-

nar oxides when the high-purity powder B was employed.

In Fig. 3c, powder B was again used to build a smaller com-

Fig. 3

—

3D construction shows EBM-built Cu components from a mixture of 99.80% Cu powder C

and a prior, high oxide powder A (a); 99.99% Cu powder B (b); and 99.99% Cu powder B built at

elevated temperature (c). Arrow denotes build direction.

TABLE 1 — SUMMARY OF MEASURED EBM FABRICATED COPPER

MATERIAL PROPERTIES

Wrought

Wrought

EBM

Ti6Al4V

EBM

C10100

Ti6Al4V

*

(ASTM F1472)

Copper

Copper

Density

>99.9% — 8.84 g/cm

3

8.90 g/cm

3

Electrical conductivity

—

— 97% IACS 102% IACS

@ 20˚C

Thermal conductivity

—

— 390 W/m*K 391 W/m*K

Yield strength (Rp 0.2)

950 MPa 860 MPa

76 MPa

69 MPa

Summary of measured EBM-fabricated copper material properties compared to wrought copper and the Arcam-

developed titanium alloy.

*

Arcam Ti6Al4V Material Data Sheet,

(www.arcam.com/CommonResources/Files/www.arcam.com/ Documents/EBM%20Materials/Arcam-Ti6Al4V-Titanium-Alloy.pdf)(a) (b) (c)