news

industry

Technique sheds light on martensitic transformations

Researchers at SLAC National Accelerator Laboratory,

Menlo Park, Calif., made the first direct measurements of a

small and extremely rapid atomic rearrangement, associated

with a class called martensitic transformations that dramati-

cally change the properties of many important materials, such

as doubling the hardness of steel and causing shape-memory

alloys to revert to a previous shape. Using high-pressure shock

waves and ultrashort x-ray pulses at the Linac Coherent Light

Source (LCLS), researchers observed details of how this trans-

formation changed the internal atomic structure of a model

system, perfect nanocrystals of cadmium sulfide. In the

process, they saw for the first time that the nanocrystals pass

through a theoretically-predicted intermediate state when un-

dergoing this change.

“To design and engineer new materials with desired prop-

erties, we would like to understand the detailed microscopic

pathways they follow as they transform,” says Aaron Linden-

berg, assistant professor at SLAC and Stanford. “The martensitic transformation is espe-

cially important because it occurs in so many important materials. Our technique should

ultimately help us see what’s happening in other atomic transformations as well.”

For more

information: Aaron Lindenberg, 650.725.2640,

aaronl@stanford.edu,

lcls.slac.stanford.edu.

Microcrucible crystal growth mechanism observed

Researchers from University of Bristol, University of

Birmingham, both in the UK, and the National Institute

for Materials Science, Japan, successfully grew nanowires

of a phase of the superconductor yttrium barium copper

oxide that have a constant cross-sectional area. Their

syntheses proceeds via the so-called “microcrucible

mechanism” of crystal growth, which was first proposed

to account for the growth of certain macroscopic metal

oxide whiskers in 1994, but had never been witnessed.

The observation was made using a high-resolution

transmission electron microscope with video capture and

an in-situ furnace. Researchers directly viewed molten

nanoparticles of barium carbonate migrating through a

porous yttriumand copper-richmatrix, catalyzing nanowire

outgrowth from nanosized microcrucibles on reaching the surface.

www.bristol.ac.uk.

Nanowire transistors enable next-generation electronics

A new approach to integrated circuits—combining atoms of semiconductor materials

into nanowires and structures on top of silicon surfaces—shows promise for a new gener-

ation of fast and sturdy electronic and photonic devices. Using this approach, engineers at

the University of California Davis demonstrated 3D nanowire transistors that open fur-

ther opportunities for integrating other semiconductors, such as gallium nitride, on silicon

substrates. “Silicon can’t do everything,” says Saif Islam, professor of electrical and com-

puter engineering. Circuits built on conventionally etched silicon have reached their lower

size limit, which restricts operation speed and integration density. Additionally, conven-

tional silicon circuits cannot function at temperatures above 250°C (~480°F), or handle

high power or voltages, or optical applications. Researchers created silicon wafers with

“nanopillars” of materials such as gallium arsenide, gallium nitride, or indium phosphide

on them, and grew tiny nanowire “bridges” between the nanopillars.

For more informa-

tion: Saif Islam, 530.754.6732,

sislam@ucdavis.edu,

ucdavis.edu.

ADVANCED MATERIALS & PROCESSES •

JULY 2014

14

N

ANOTECHNOLOGY

briefs

A team led by researchers from the

University of California Los

Angeles

developed a process to

control molecular growth within

the “building block” components of

inorganic materials. The method

uses nanoparticles to organize

components during a critical phase

of the manufacturing process and

could lead to innovative new

materials, such as self-lubricating

bearings for engines. It could also

make mass production of such

materials more feasible. For

example, the method could be

used for aluminum-bismuth alloys.

Aluminum and bismuth cannot be

completely mixed, but with the

nanoparticle-controlled process,

researchers created a uniform and

high performance aluminum-

bismuth alloy.

ucla.edu.

A Swedish-German research team

successfully tested a new method

of producing ultra-strong cellulose

fibers at

Deutsches Elektronen-

Synchrotron’s (DESY)

research

light source PETRA III in Germany.

The novel procedure spins

extremely tough filaments from

tiny cellulose fibrils by aligning

them in parallel during the

production process: Nanometer-

sized cellulose fibrils are fed

together with water through a

small channel. Two additional

water jets coming in perpendicular

from left and right accelerate fibril

flow. Following acceleration, all

nanofibrils align themselves more

or less parallel with the flow. Salt is

then added to the outer streams,

which makes the fibrils attach to

each other, thereby locking the

filament structure. Once the

filaments dry, they shrink to form a

strong fiber.

www.desy.de.

Artist’s impression of the

production of ultra-strong

cellulose fibers. Courtesy of

DESY/Eberhard Reimann.

The transformation of

cadmium sulfide

nanocrystals from a

hexagonal arrangement

(left) to a cubic one (right).

A slightly compressed

intermediate state is

portrayed in the middle.

Courtesy of Greg Stew-

art/SLAC.

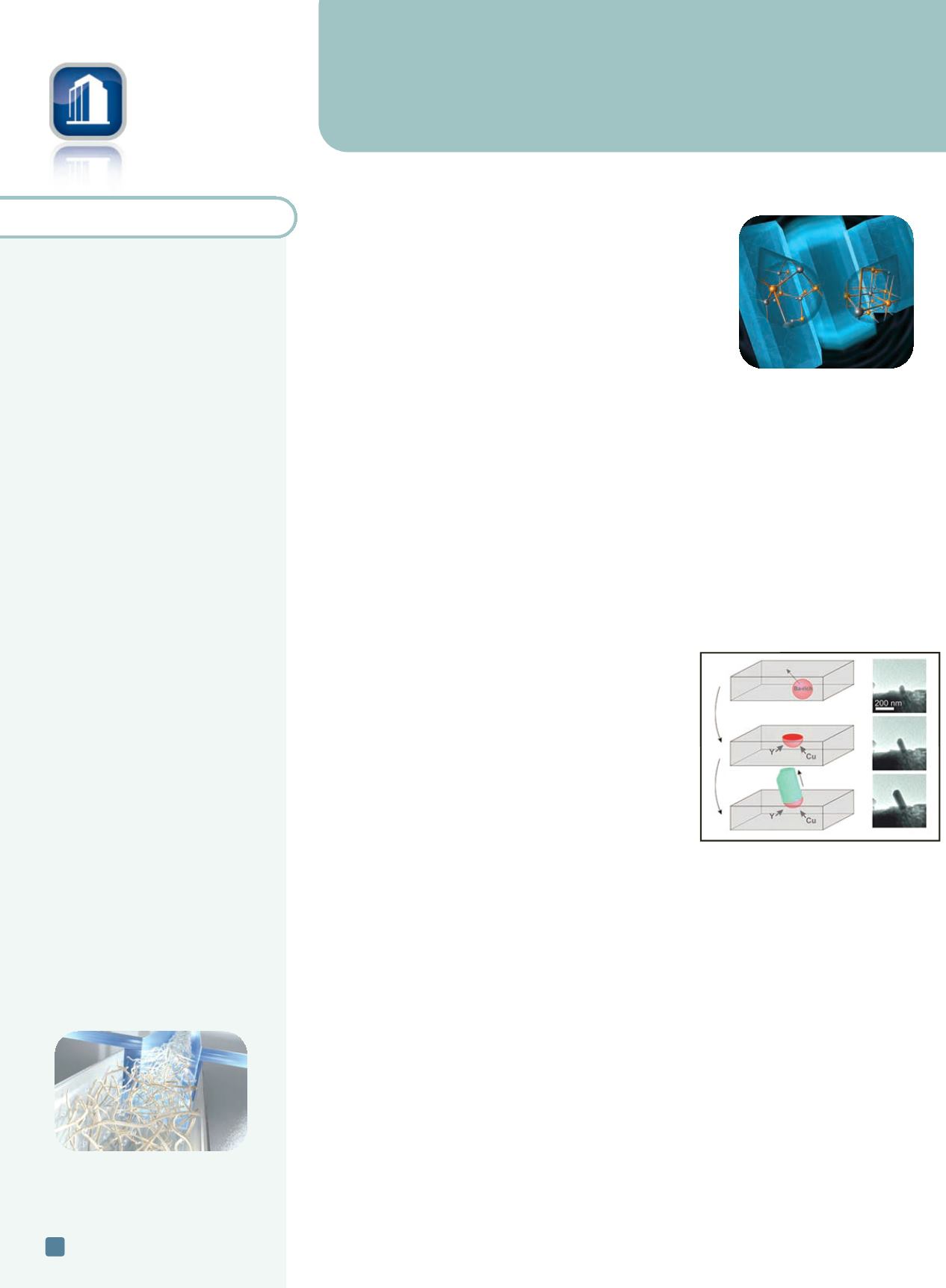

Schematic of molten barium-

rich nanoparticles moving to the

surface of an yttrium- and

copper-rich matrix.