news

industry

briefs

Researchers at

University of

California Santa Barbara

created

a compound semiconductor of

nearly perfect quality with

embedded nanostructures

containing ordered lines of atoms

that can manipulate light energy in

the mid-infrared range. More

efficient solar cells, better

biological imaging, and the ability

to transmit massive amounts of

data at higher speeds are potential

applications. Erbium, which can

absorb light in the visible as well

as infrared wavelength, is key to

the technology. Erbium was paired

with antimony and the resulting

compound was embedded as

semimetallic nanostructures within

the semiconducting matrix of

gallium antimonide.

engineering.ucsb.edu.

An artist’s concept

of nanometer-size

metallic wires and

metallic particles

embedded in

semiconductors.

Courtesy of Peter

Allen.

Nanyang Technological

University (NTU),

Singapore,

launched a new $30 million 3D

printing facility to study medical

devices and tissue printing, among

other applications. The NTU

Additive Manufacturing Centre

(NAMC) also signed a $5 million

joint laboratory agreement with

SLM Solutions,

Germany, a 3D

printer manufacturer. Named

SLM

Solutions@NAMC,

the lab aims to

develop next-generation 3D

printers that can print very large

parts using new types of materials.

It will also develop platforms that

can print multiple materials in a

single build.

www.ntu.edu.sg.

3D-printed jewelry displayed at

the NTU Additive Manufacturing

Centre debut. Courtesy of NTU.

Newmethod enables industrial scale graphene production

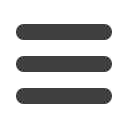

Researchers at Massachusetts Institute

of Technology (MIT), Cambridge, and the

University of Michigan, Ann Arbor, dis-

covered a way to produce graphene in a

process that lends itself to scaling up, by

making graphene directly on materials

such as large sheets of glass. Currently,

most methods first grow the material on a

film of metal, such as nickel or copper, ex-

plains MIT mechanical engineering pro-

fessor A. John Hart. “To make it useful,

you have to get it off the metal and onto a

substrate, such as a silicon wafer or a poly-

mer sheet, or something larger like a sheet of glass,” he says. “But the process of transfer-

ring it has become much more frustrating than the process of growing the graphene itself,

and can damage and contaminate the material.”

The new work, Hart says, still uses a metal film as the template—but instead of mak-

ing graphene only on top of the metal film, the process makes it on both sides. The sub-

strate in this case is silicon dioxide, with a film of nickel on top. Using chemical vapor

deposition (CVD) to deposit a graphene layer on top of the nickel film yields graphene on

both sides. The nickel film can then be peeled away, leaving just the graphene on top of the

nonmetallic substrate. This eliminates the need for a separate process to attach the

graphene to the intended substrate

. For more information: A. John Hart, 617.324.7022,

ajhart@mit.edu,

mechanosynthesis.mit.edu.

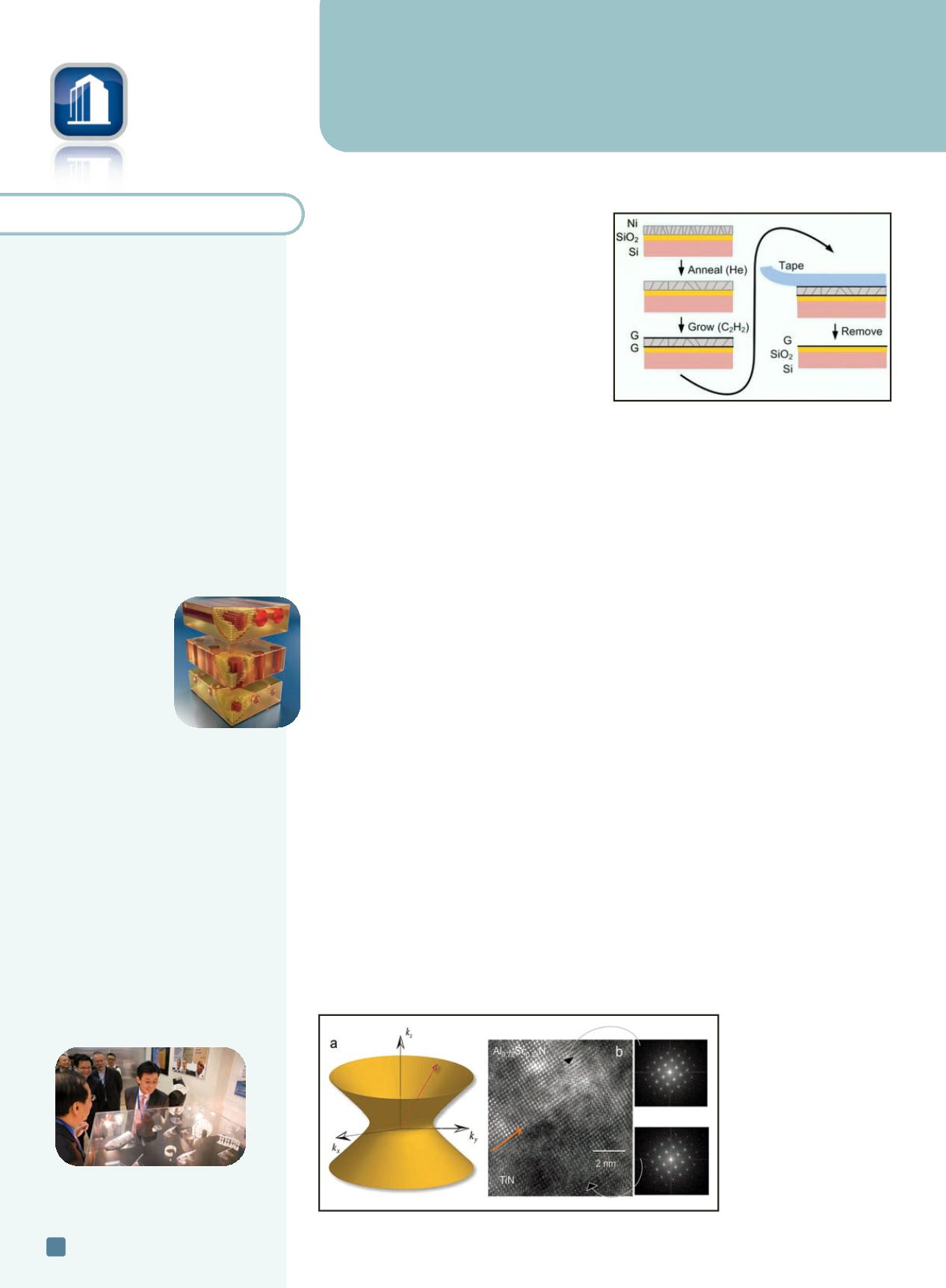

Hyperbolic metamaterials one step closer to reality

Researchers at Purdue University, West Lafayette, Ind., took another step toward practi-

cal applications for

hyperbolic metamaterials,

ultrathin crystalline films that could bring op-

tical advances including powerful microscopes, quantum computers, and high-performance

solar cells. New developments are similar to advances that ushered in silicon chip technol-

ogy, says Alexandra Boltasseva, associate professor of electrical and computer engineering.

Metamaterials have engineered surfaces that contain features, patterns, or elements,

such as tiny antennas or alternating layers of nitrides that enable unprecedented control of

light. Under development for about 15 years, metamaterials owe their unusual potential to

precision design on the nanometer scale. Optical metamaterials harness clouds of elec-

trons called surface plasmons to manipulate and control light. However, some of the plas-

monic components under development rely on using metals such as gold and silver, which

are incompatible with the complementary metal-oxide-semiconductor (CMOS) manufac-

turing process used to construct integrated circuits and do not transmit light efficiently.

Now, researchers created superlattice crystals from layers of titanium nitride and alu-

minum scandium nitride. The superlattices were created with epitaxy, and the layers were

grown inside a vacuum chamber using magnetron sputtering.

purdue.edu.

ADVANCED MATERIALS & PROCESSES •

JULY 2014

10

E

MERGING

T

ECHNOLOGY

Illustration of a new process for making

graphene directly on a nonmetal substrate.

Courtesy of the researchers.

A metamaterial’s hyperbolic

dispersion of light, left. At

center is a transmission

electron microscope image

showing the interface of

titanium nitride and

aluminum scandium nitride

in a superlattice. Two

images created using fast

Fourier transform to see

individual layers in the

material, right. Courtesy of

Purdue University.