Ultrasonic waves make nimble hands for microscopic tasks

Researchers from the Universities of Bath, Bristol,

and Dundee, all in the UK, discovered that ultrasonic

waves can be used to grab several microparticles at a

time, essentially creating a pair of invisible “ultrasonic

hands” that can move tiny objects, such as cells, under

a microscope. Using plastic spheres the size of biologi-

cal cells, objects could be moved along independent

paths and then carefully brought together. These capa-

bilities provide new tools to study cells that could help

biologists and medical personnel perform a variety of

delicate tasks such as sorting or assembling cells into

patterns for tissue engineering, stem cell work, and regenerative medicine.

“Sophisticated microparticle manipulation is possible using a relatively simple desktop

apparatus that can be used with a standard microscope system. We believe this has the po-

tential to radically improve results in bioscience labs where pinpoint positioning of cells is

a useful research tool,” says Charles Courtney of the University of Bath’s mechanical engi-

neering department.

www.bristol.ac.uk.

Multiscale modeling project targets aerospace costs

The EU CRASHING project, funded by the Clean Sky Joint Technol-

ogy Initiative (JTI-Clean Sky) within the EU’s 7th Framework Program,

aims to develop new methods of testing aerospace materials through

multiscale computer simulation to save time, money, and lives. The two-year project will

address costs by building on recent progress in multiscale modeling. CRASHING focuses

on composite materials used in current aircraft design, as well as innovative materials with

potential future applications.

Computer models will provide accurate simulations of what happens when an aircraft

crash lands, is hit by ice, or is exposed to other extreme impacts. Hopefully CRASHING

will lead to a significant reduction in the number of physical tests required for aircraft cer-

tification and reduce development time for new structural components. The project is

being led and coordinated by the IMDEA Materials Institute in Spain, which is responsi-

ble for development and validation of multiscale models at different levels. The other con-

sortium partner, Carlos III University of Madrid, is in charge of experimental

characterization of materials under impact.

materials.imdea.org.

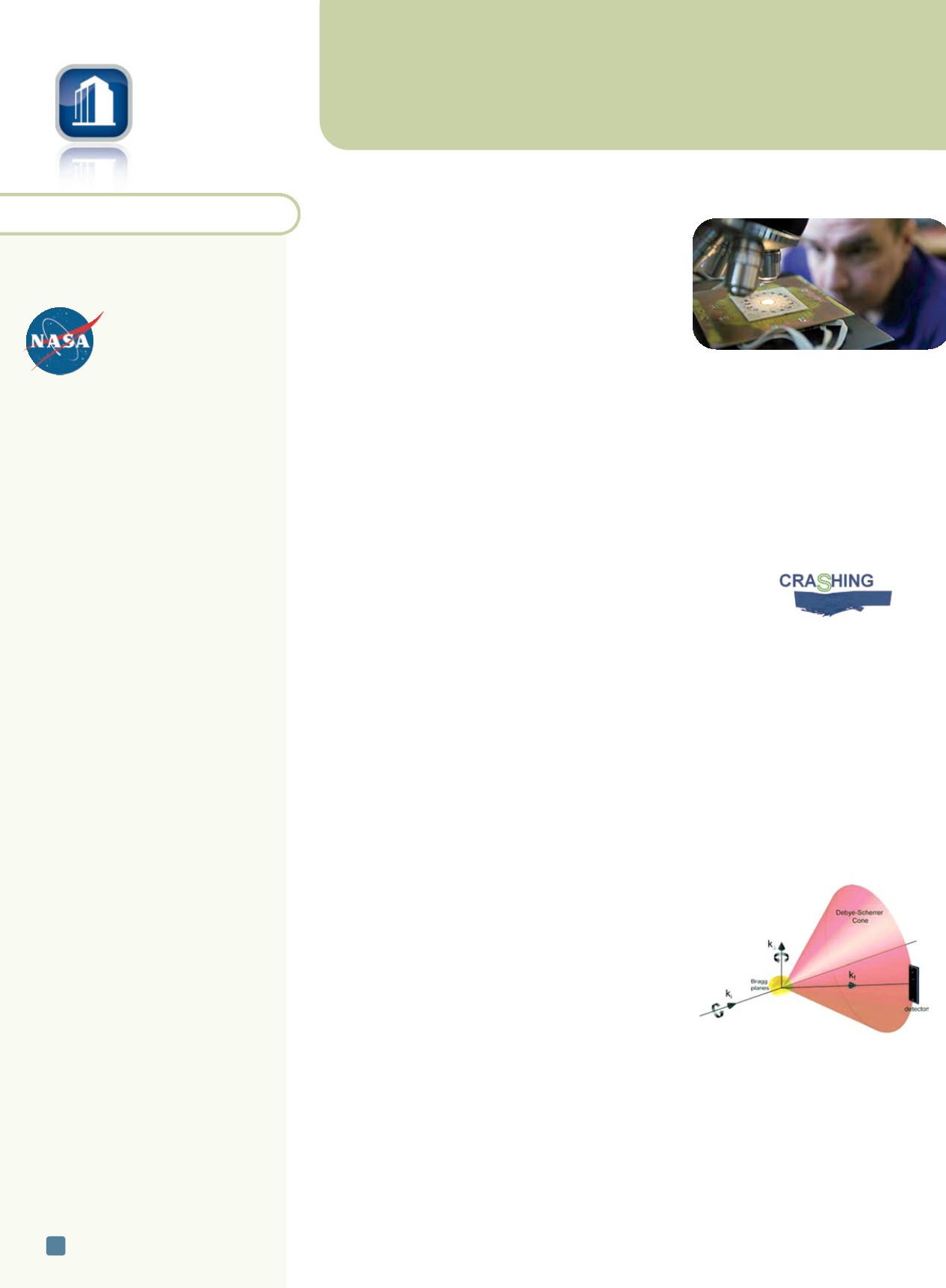

Rotational x-ray tracking opens up new class of materials

Over the past 20 years, there has been increasing interest and development in

measuring slow dynamics in disordered systems at the nanoscale. Some

techniques developed during recent years to study the dynamic proper-

ties of these materials include x-ray photon correlation spectroscopy

(XPCS) and speckle visibility spectroscopy (SVS). However, both

techniques are limited in that they require specialized x-ray

facilities and nanoscale resolution.

Scientists at the University of Illinois at Urbana-

Champaign, Argonne National Lab, Centre for Free-Electron Laser Sci-

ence, Germany, and University College London, UK, developed a new

technique called rotational x-ray tracking (RXT). The technique was used

to study small crystalline particles that become immobilized when they

form a colloidal gel under certain conditions. Instead of characterizing the gel as an immo-

bile colloidal dispersion, scientists showed how particles in the gel actually undergo angu-

lar motion. The precise nature of the rotational motion uniquely measures the nanoscale

elastic properties of the gel network. These findings open up an entirely new class of dy-

namic systems and materials, according to researchers.

iucr.org.

briefs

The

Innovative Technology

Partnerships Office at NASA

Goddard Space Flight Center,

Greenbelt, Md., will

collaborate with

Rolls-

Royce,

Indianapolis, to

develop braze joint

performance prediction

methods for critical structures

subject to complex loading

conditions. Rolls-Royce will

establish a braze failure

assessment diagram (FAD) that

can be used to define acceptable

stress combinations and margins

of safety for braze joints and braze

repair structures. NASA will receive

verification of its FAD methodology

for failure prediction of structural

brazed joints on actual industrial

applications.

nasa.gov, rolls-royce.com.

Submissions are welcome for the

Buehler Microstructure of

Materials Calendar 2015,

with

publication open to anyone who

has achieved a level of excellence

in materials preparation.

Photomicrographs can include

microstructural details or hardness

indents of any metallic,

nonmetallic, geological, or bio-

related materials. Images must be

obtained through a light optical

microscope or hardness tester and

cannot be digitally colored or

enhanced. Selected entries will

receive an honorarium of $200.

Submission deadline is July 31. For

more information: 847.295.6500,

calendar@buehler.com.

WuXi PharmaTech Inc.,

Shanghai,

expanded its materials

characterization testing facility in

St. Paul, Minn. The new 20,000-

sq-ft laboratory offers expanded

capacity for existing services, such

as particle identification and

extractable/leachable testing, and

adds a new service—dynamic

light scattering for nanoparticle

characterization. These services

are required by the FDA for filings

of medical devices or biologics.

wuxiapptec.com.

ADVANCED MATERIALS & PROCESSES •

JULY 2014

8

T

ESTING

C

HARACTERIZATION

news

industry

Researchers create ultrasonic

hands that can grip

microparticles. Courtesy of

University of Bath.

Bragg scattering

geometry for the

experiment.

Courtesy of

M.Liang, et al.