news

industry

Toward solving the world energy crisis

Northwestern University, Evanston, Ill., scientists discovered that a surprising mate-

rial, selenide, is the best at converting waste heat to useful electricity. This outstanding

property could potentially provide enormous energy savings. Researchers found that the

crystal form of the chemical compound tin selenide conducts heat so poorly through its lat-

tice structure that it is the most efficient thermoelectric material known. Unlike most ther-

moelectric materials, tin selenide has a simple structure, which provides the key to its

exceptional properties. The efficiency of waste heat conversion in thermoelectrics is re-

flected by its figure of merit, ZT. Tin selenide exhibits a ZT of 2.6, the highest reported to

date at around 650°C. The material’s extremely low thermal conductivity boosts the ZT to

this high level, while retaining electrical conductivity.

northwestern.edu.

Impurity size could help or hinder superconductor performance

North Carolina State University, Raleigh, re-

searchers found that impurities can either hurt per-

formance—or possibly provide benefits—in a key

superconductive material expected to find use in a host

of applications, including future particle colliders. Im-

purity size determines whether it helps or hinders the

material’s performance. “Bismuth strontium calcium

copper oxide (Bi2212) is the only high-temperature su-

perconductor that can be made as a round wire, and is

expected to have applications in magnets for a wide

range of uses,” says Ph.D. student Golsa Naderi.

To use Bi2212 for potential applications, it needs

to be formed into a multifilamentary wire, which con-

tains 500-1000 Bi2212 filaments embedded in silver,

and then heat-treated to nearly 900°C. However, this processing results in impurities in

the material. These impurities largely consist of porosity and bismuth strontium copper

oxide (Bi2201). Researchers found that nanoscale impurities, from 1.2 to 2.5 nm wide, ap-

pear to improve Bi2212’s performance as a superconductor.

ncsu.edu.

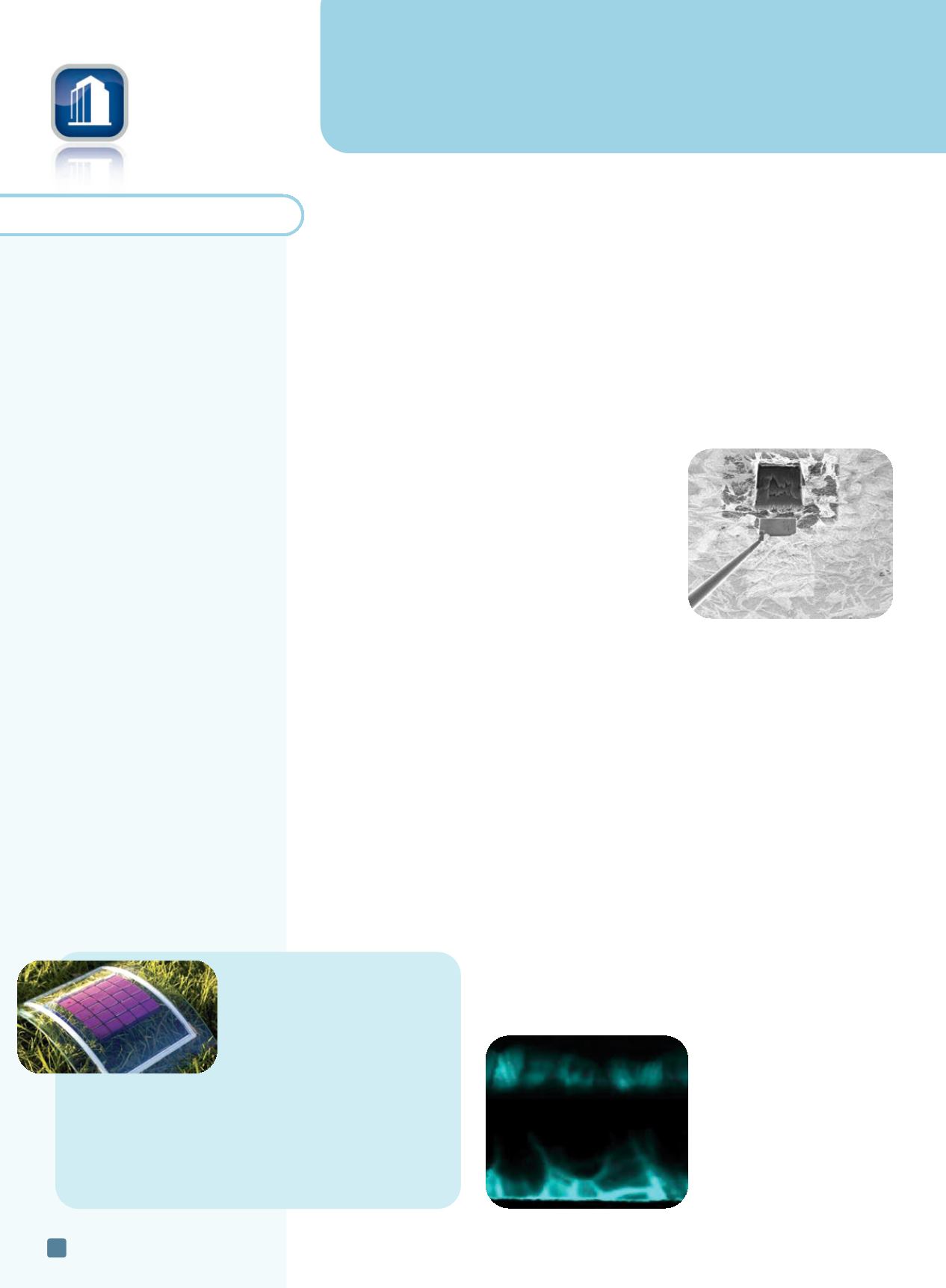

Thin-film solar cell mystery solved

Treating cadmium-telluride (CdTe) solar cell materials with cadmium-chloride improves

their efficiency, but researchers have not fully understood why until now. A research team

fromOak Ridge National Laboratory, Tenn., the University of Toledo, Ohio, and the National

Renewable Energy Laboratory, Golden, Colo., used electron microscopy and computational

simulations to explore the physical origins of the unexplained treatment process.

Using state-of-the-art electron microscopy techniques to study the thin films’ structure and

chemical composition after treatment, researchers found that

chlorine atoms replaced tellurium atoms within the grain bound-

aries. This atomic substitution creates local electric fields at the

grain boundaries that boost the material’s photovoltaic perform-

ance instead of damaging it.

ornl.gov, utoledo.edu,

nrel.gov.Cross-sectional electron

beam-induced current maps

show the difference in cadmium

telluride solar cells before

(pictured above) and after

(below) cadmium chloride

treatment. The increased

brightness after treatment

indicates higher current

collection at grain boundaries.

Courtesy of ORNL.

ADVANCED MATERIALS & PROCESSES •

JULY 2014

12

E

NERGY

T

RENDS

briefs

The U.S. Department of Energy

will support the application of

advanced materials and

manufacturing techniques to

develop next-generation

hydropower technologies with a

$4.4 million grant. As part of the

Clean Energy Manufacturing

Initiative,

the funding will help

researchers develop low cost,

integrated hydropower turbine-

generator sets that can produce

cost-competitive electricity at low-

head sites. The funding will also

help pioneer new designs that

apply advanced materials and

innovative manufacturing

techniques to next-generation,

low-head hydropower systems.

energy.gov.Jyllian Kemsley,

senior editor at

Chemical & Engineering News,

by

the

American Chemical Society,

Washington, points out in a recent

article that radiation can cause a

range of problems from

temperature misreadings in

electronic devices to nuclear

power plant explosions. These

problems could be solved by

finding the right materials to deal

with high-radiation environments.

In the case of nuclear power

plants, steel might be better than

zirconium for housing fuel pellets.

For other applications, however,

scientists found that although

radiation punches holes in carbon

nanotubes, when bundled together,

radiation can make them 100

times more rigid.

acs.org.

Impurity size can either hurt

performance—or possibly provide

benefits—in the superconductive

material Bi2212. Courtesy of Golsa

Naderi.

MatHero, a new project coordinated by

Karlsruhe Institute of Technology

(KIT),

Germany, aims to make organic

photovoltaics competitive with their in-

organic counterparts by enhancing effi-

ciency, reducing production costs, and

increasing their lifetime. MatHero—new

materials for highly efficient and reliable

organic solar cells—covers the com-

plete value chain of organic solar cell

fabrication, from polymer design and

synthesis to module fabrication and

characterization to stability assessment. The project goal is an environ-

mentally compatible printed organic solar module initially for use in

off-grid applications.

kit.edu.

Plastic solar cells are

lightweight, mechanically

flexible, and offer many

advantages over

inorganic solar cells.