ers, condensers, and evaporators used in automotive, aero-

space, nuclear, and energy industries.

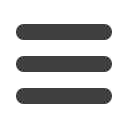

Vacuum aluminum brazing furnaces

Typical VAB furnaces are either single-chamber (batch

type) or multiple-chamber (semi-continuous). Batch type

furnaces are usually loaded horizontally, but can be de-

signed for vertical loading. Semi-continuous furnaces are

horizontally loaded and are typically automated using load

carriers and external conveyor systems.

Batch furnaces tend to be simpler in design (one load-

ing/unloading door), less expensive, and easier to maintain

(Fig. 2) than semi-continuous furnaces. Semi-continuous

furnaces have higher production rates because of the

multi-chamber design and operate more efficiently by not

having to cool heating zones or heat cooling zones.

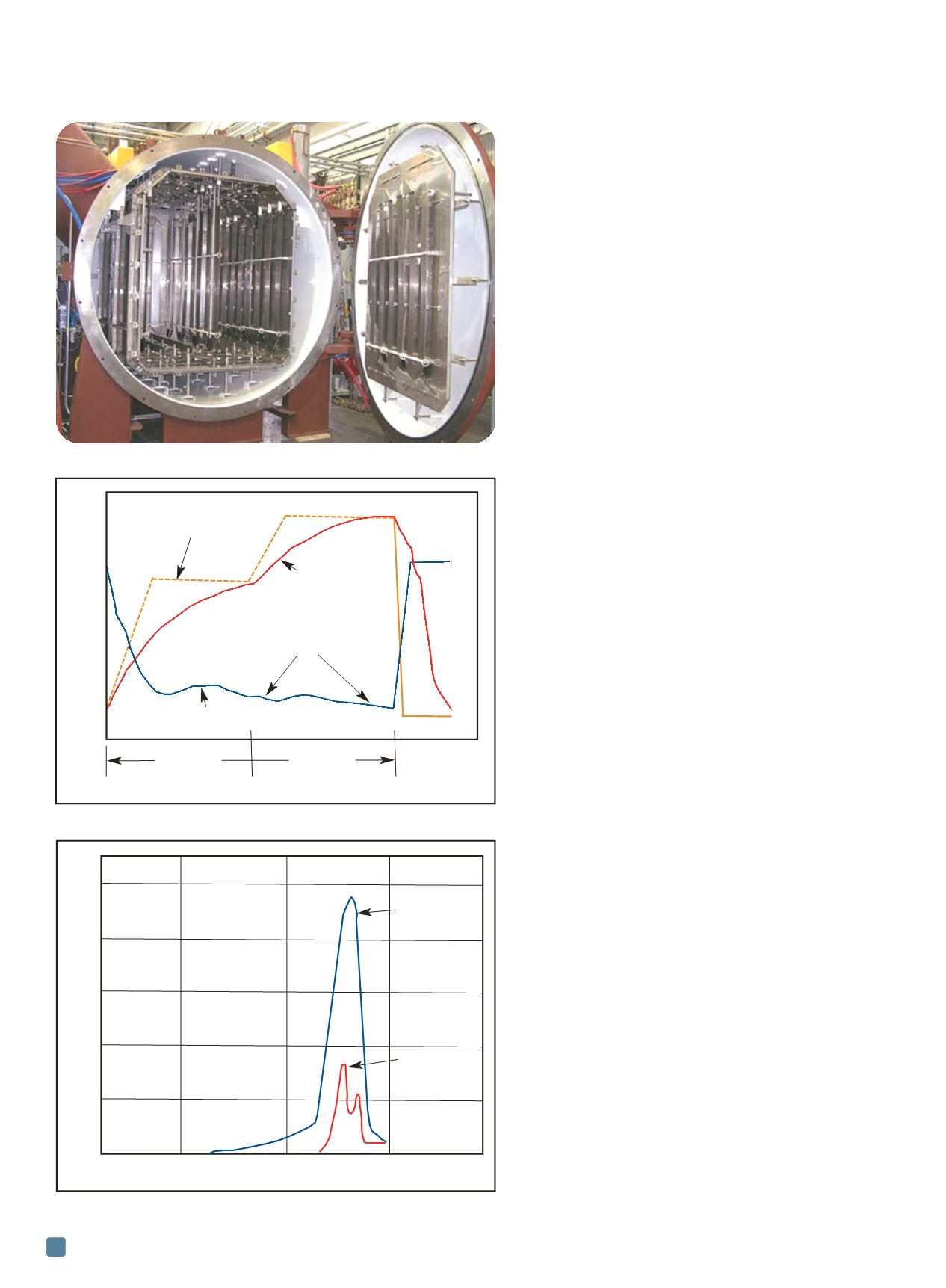

The VAB process is typically a relatively short cycle due

to the fast pumping and heating characteristics of the fur-

nace, excellent temperature uniformity at soak tempera-

tures, and high thermal conductivity of the aluminum parts

being brazed. Figure 3 shows a typical VAB cycle.

Vacuum pumping capacity must be adequately sized in

order to minimize pump downtime of a new load to a deep

vacuum level, so as to initiate the heating cycle and have

adequate throughput to keep up with outgassing taking

place during the heating cycle. This outgassing takes place

due to magnesium vaporization. Deep vacuum level is an

important process parameter because it ensures a relatively

pure environment for brazing (less PPM of oxygen).

Magnesium plays key role

A key component of VAB is magnesium use as an ad-

ditive to the filler metal and/or base metal of the parts to

be brazed. It is necessary in this fluxless brazing environ-

ment because:

• Magnesium vaporizes at roughly 1058°F (570°C) and

acts as a “getter” for oxygen and water vapor, thus

improving the brazing vacuum purity

• Magnesium reduces alumina oxide on aluminum’s

surface, promoting uniform accelerated wetting of

joint surfaces

The following reactions occur during the vacuum braz-

ing process:

Mg + H

2

O —> MgO + H

2

Mg + O

2

—> 2 MgO

3 Mg + Al

2

O

3

—>

3

MgO + 2 Al

Mg + N

2

—> Mg

3

N

2

Magnesium vaporization in a vacuum environment can

be seen in Fig. 4. Also known as a “mag burst,” magnesium

vaporization produces heavy outgassing for a short period.

Figure 4 shows that slower heating rates reduce the magne-

sium vaporization rate. Due to this gas load, vacuum

pumps must be adequately sized to maintain a good work-

ing vacuum (10

-4

to 10

-5

torr range).

Precise temperature control and uniformity are also

important process parameters. Accepted temperature uni-

ADVANCED MATERIALS & PROCESSES •

JULY 2014

16

Fig. 2 —

Batch vacuum aluminum brazing furnace.

Fig. 3 —

Typical vacuum aluminum brazing cycle.

Fig. 4 —

Magnesium vaporization in vacuum vs. temperature.

Time

1/2 cycle

1/2 cycle

Vacuum

temperature

Program

Part temperature

10

-5

torr range

≥ 1.10

-4

torr

500

550

600

Temperature, °C

Heating rate

10°C/min

2°C/min

1.0

0.8

0.6

0.4

0.2

Mg loss rate