Laser finish details

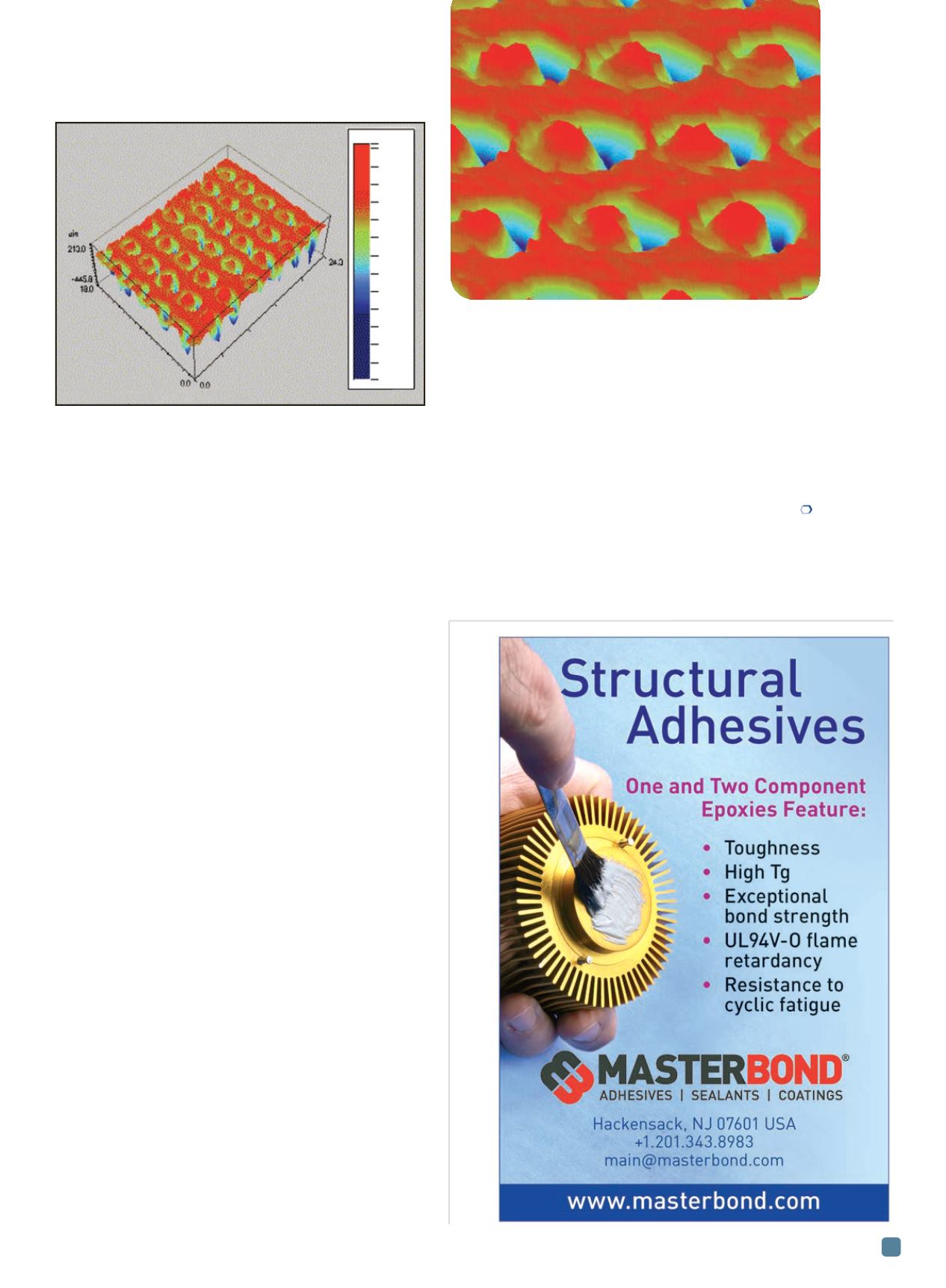

State-of-the-art laser texturing, such as that developed

in Japan and now being produced as LaserMatte by Greer

Steel in North America, creates a uniform matte finish on

the work rolls by consistently imparting microcraters in the

surface of the steel. These microcraters produce a relatively

large, negative skew (Rsk) material at typical Ra levels of 25

to 50 μin. (Figs. 5 and 6), compared with the positive skew

pattern evident in the other matte finishes. 3D imaging is

used to perfect surface finishes, which provides a micro-

scopic lubrication distribution system on the metal surface

that continually feeds lubricant into the die during forming.

A 2.8-kW CO

2

laser precisely creates microcraters by

using a microscopic beam of light energy that is inter-

rupted by an aluminum chopper wheel. Highly precise

teeth chop the beam into pulses. Each segment of light

strikes the surface of the roll as it turns on a lathe, creating

localized melting on the alloy surface. A blast of assist gas

displaces the molten metal, forming a surface feature sim-

ilar to a volcanic crater. Uniformity and consistency are

achieved by repeating this process 40,000 times per sec-

ond in a helical pattern as the laser moves slowly along a

track parallel to the turning roll. Millions of small craters

are precisely placed on the roll surface, with their pitch and

size controlled by a multi-axis regulator.

Laser texturing creates a highly uniform, precise metal

surface topography that cannot be produced by conven-

tional methods. The predictable and repeatable surface

brings numerous benefits to metal formers that extend far

beyond improved lubricant-holding capabilities. Benefits

of using laser-textured materials include:

• Reduced friction and galling, resulting in improved

part quality

• Longer tool and die life

• Improved process yield

• Avoidance of costly tool and die coatings

• Increased productivity due to reduced press

downtime

• Improved metal flow in the die, as strains that cause

breakage are prevented, thus allowing the metal to

achieve its forming potential

• Lower energy costs achieved through greater process

and production efficiencies

Surface finishes affect metal formability, lubrication re-

tention, surface contact area, paint adherence, appearance,

and surface bonding area in metal forming. They also af-

fect functionality and wear rates between mating surfaces

in end-use applications. Achieving an optimummatte sur-

face is a challenge, but laser texturing technology is pro-

viding metal formers with a reliable, cost-effective process

that results in both immediate and long-term benefits.

For more information:

Todd Daenzer is chief operations and

quality officer at Greer Steel Co., 624 Boulevard St., Dover,

OH 44622, 330/343-8811,

www.greersteel.com.

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

27

Fig. 5 –

Laser textured surface in 3D.

Fig. 6 –

Laser surface at high magnification in 3D.

uin

213.03

100.00

-50.00

-200.00

-445.78