ADVANCED MATERIALS & PROCESSES •

MARCH 2014

26

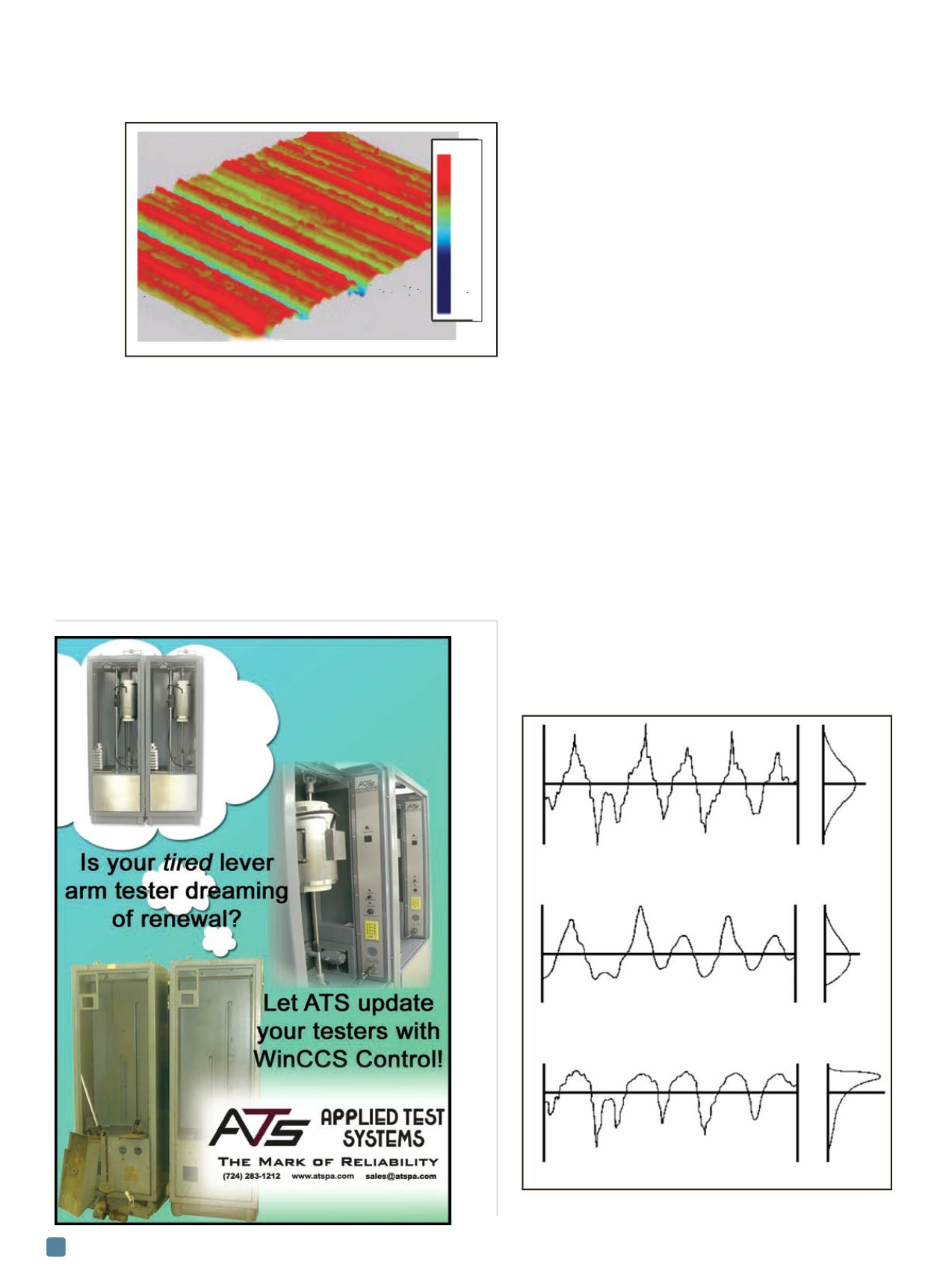

a tool electrode and work roll, which results in tiny, ran-

dom sharp craters in the surface. In the 3D images, red in-

dicates height and blue indicates depth.

As the 3D images show, the blasted surface exhibits

greater variability than the EDT steel surface, though both

show pronounced peaks on the material’s surface. These

pinpoint peaks are prone to breaking and/or deforming

during forming and drawing and can lead to galling, pre-

mature tool wear, and die lube contamination. The EDT

surface is generally the more consistent type of these two

traditional matte finishes.

Grinding wheels or abrasive media can be used to

achieve a ground finish to enhance retention of die lube.

While this method increases surface roughness, surface

properties are unidirectional and exhibit notable differ-

ences in the longitudinal and transverse directions, mak-

ing it unacceptable for most drawing applications. Figure

3 shows the general appearance of steel rolled with

ground rolls.

When analyzing peak formations on material sur-

faces, the “skewness” of the surface should be measured

to compare the relationship of peaks and valleys on the

steel surface. If a surface is skewed toward the positive

side, there is more peak than valley and vice versa. Fig-

ure 4 shows a profilometer trace of both of these sur-

faces, as well as a neutral surface with equal peak/valley

distribution.

An LBT generated surface inherently exhibits a neg-

ative skew, while those produced with traditional finish

methods tend to exhibit a positive skew. This difference

in surface topography is shown in Fig. 5. Figure 6 shows

an enhanced, higher magnification view of the LBT sur-

face, further demonstrating both the lack of pinpoint

peaks (undesirable in the forming and/or drawing

process) and the large surface bearing area provided by

this type of finish.

In addition to the negative skew imparted to materi-

als processed with LBT rolls, the technology achieves a

deterministic finish verses the stochastic or “random in

nature” surface that is imparted by traditional matte fin-

ishes, enabling greater consistency and predictability

during forming.

Fig. 3 –

Ground roll surface finish in 3D.

Fig. 4 –

Surface texture skew is extremely important.

uin

199

50

-100

-250

-400

-520

Neutral profile R

s

k~0

Positive skew profile R

s

k>0

Negative skew profile R

s

k<0