Faster, Automatic Identification of

Particle Contamination

I

ndustries such as automotive, electronics, and med-

ical devices are particularly sensitive to the perform-

ance of precision-manufactured parts. When parts

fail, sometimes due to particulate contamination that

occurs in the manufacturing process, incomplete coat-

ings or engine damage can occur.

The ability to identify particle contaminants and

their origins can be an advantage in manufacturing op-

erations. In automobile production, for example, con-

taminants range from metal shavings to abrasive

residues to small fibers. As engine tolerances tighten,

particles that impact performance have gotten smaller.

Residue can remain throughout the manufacturing

process, causing issues when engines are finally tested.

Traditional methods of monitoring surface clean-

liness such as gravimetric analysis can calculate con-

taminant total bulk weight, but do not produce

individual particle data. As a result, components may

pass gravimetric testing, yet fail to function due to in-

dividual “killer” particles that can cause issues. Some

manufacturers see dangerous abrasive contaminants,

such as aluminum oxide, that are just 2 μm, which are

not detected via traditional gravimetric testing yet

cause engines failure.

Traditional methods

Many options for monitoring particles on automo-

tive component surfaces are available. It is important

to thoroughly understand the features and benefits of

each approach.

Bulk/gravimetric testing —

Bulk/gravimetric meas-

urements have long been used to quantify foreign ma-

terial presence by measuring filter weight before and

after part flushing. The part or assembly is typically

flushed and residue is collected on a pre-weighed fil-

ter. The loaded filter is dried and weighed, indicating

the total mass of collected debris. This method only

provides a gross or an undifferentiated measure of the

amount of material present. The weight or volume of

filtered materials sheds no light on particle size, shape,

or composition, which is necessary to improve design

or control processes.

Particle counters —

Particle flow-counters disperse

particles in fluid. Particles are then passed through a

flow cell where they are detected by an optical or laser

sensor. Such devices can accurately count thousands of

particles per second, and often provide a graph of par-

ticle size distributions. However, most counters assume

particles are perfectly round. As a result, particle

counter manufacturers report out an equivalent diam-

eter using various algorithms, making comparisons be-

tween particle size reports from different

manufacturers difficult and/or inconclusive. Particle

counters also may experience false positives, which

typically result from air entrapment or water in the oil.

While these units are useful for monitoring trends of

established particle populations, they are less valuable

for understanding unknown or changing particle pop-

ulations (clear signs of changes in surface contamina-

tion on a part or component).

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

28

TECHNICAL SPOTLIGHT

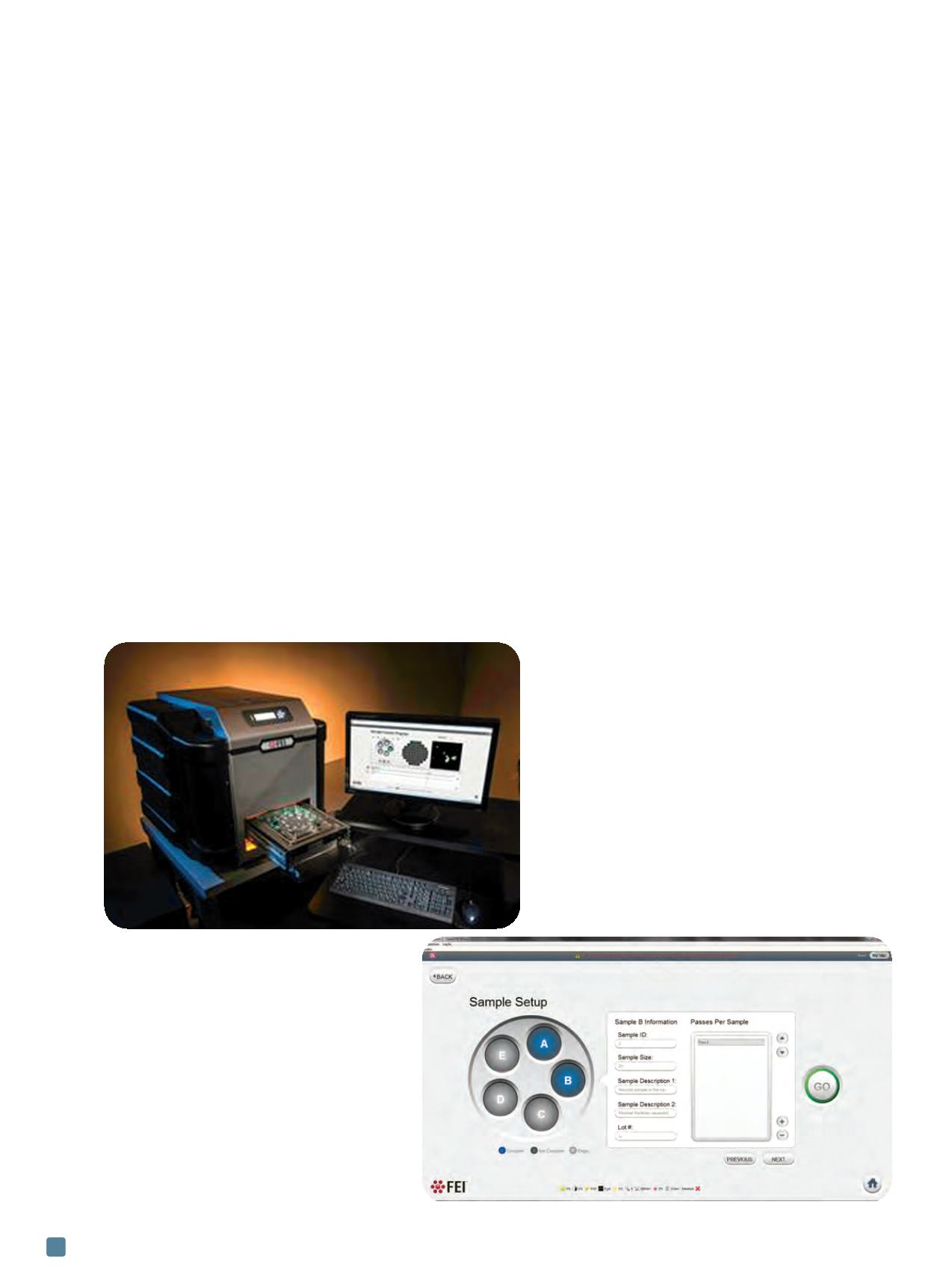

CleanCHK system

with automated sample setup.

Screenshot of sample setup

screen on CleanCHK.