ADVANCED MATERIALS & PROCESSES •

MARCH 2014

23

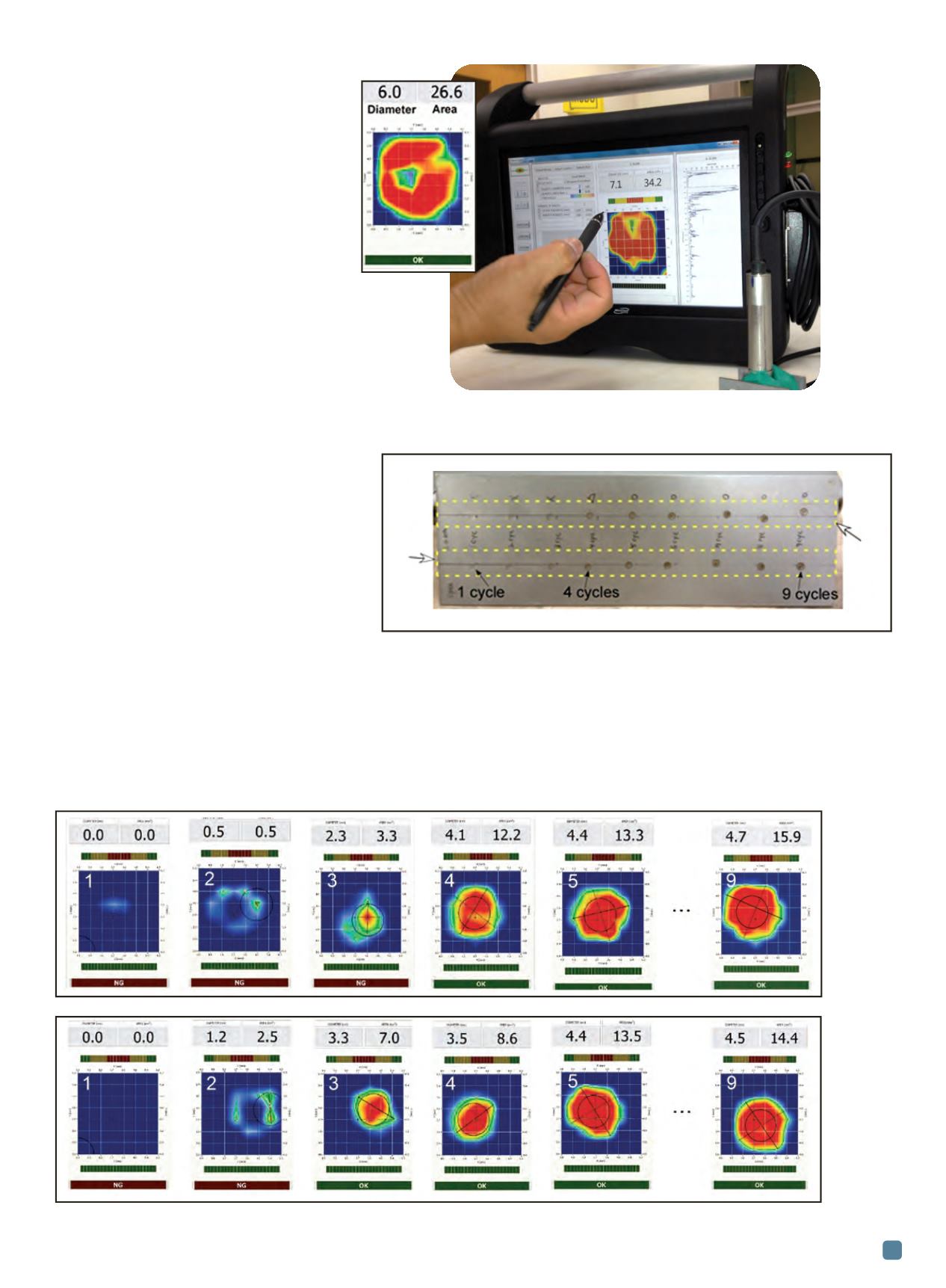

time with feedback. This new NDI system

not only reduces the need for destructive

testing of spot welds in manufacturing, but

also assesses the structural integrity of prod-

ucts with great cost-savings and efficiency.

In order to generate 2D C-scan weld images, the

phased array electronic circuit first activates the MPA

probe with commands from the data processing software.

Ultrasonic signals detected by the MPA probe are then fed

into the imaging algorithm for the fused and non-fused

joining areas being inspected. A color-coded ultrasonic C-

scan image and additional data such as nugget diameter

and fused area are displayed on the screen.

The system processes ultrasonic signals as

they are detected by individual subgroups of the

probe array using two electronic gates, one for

the front surface reflection and the other for in-

terface reflection. An ultrasonic image is plotted

as raw ultrasonic data is processed in real-time

with the dual gate imaging algorithm. Operator

feedback occurs in a fraction of a second and

probe adjustment is relatively fast and easy com-

pared to other systems that require probe repo-

sitioning if results are unsatisfactory.

Test results

A set of resistance spot welds with two-sheet stackups

and thicknesses at the lower limit of 0.7 mm were prepared.

Two rows of nine spot welds each were placed on the test

sample shown in Fig. 3. For this sample, a constant current of

6 kA was applied for all welds, while the number of cycles

was varied from 1-9 at an increment of one cycle for each

weld. Spot welds on the sample stack were tested using the

SpotSight inspection system and results are shown in Fig. 3.

The number in the upper left corner of each image in

Fig. 4 indicates howmany electric current cycles were used

to form weld nuggets. For both upper and lower rows, an

acceptable spot size weld was measured after five cycles.

Fig. 2 —

EWI SpotSight ultrasonic nondestructive inspection

system and C-scan image of a resistance spot weld nugget

with porosity in the center section (inset).

Lower

Upper

row

row

Fig. 3 —

Test sample with two rows of resistance spot welds.

Fig. 4 —

Ultrasonic

images of

spot weld

nuggets

for the

test

sample

plate

shown in

Fig. 3.

Welds in

the upper

row (a),

welds in

the lower

row (b).

(a)

(b)