ADVANCED MATERIALS & PROCESSES •

MARCH 2014

29

Optical microscopes —

Individual particles are

observed and their size is estimated. This

manual particle sizing is simple to perform,

but is tedious and time-consuming. In recent

years, optical microscopes evolved to include

cameras and motorized stages. By interfacing both

to a computer, automating the particle detection/siz-

ing process is possible. It is practical to routinely meas-

ure distributions consisting of thousands of particles

and sort them by size and shape. However, the chemi-

cal composition of the particles remains unknown.

Alternative method

Determining the elemental composition of these

microscopic particles helps define the contaminant’s

origin and provides concrete information that allows

manufacturers to conduct quality control analyses to

improve production processes. When a product

needs to be verified as suitably free of a specific kind

or class of particulate contaminant, such as a toxic or

abrasive material, other methods can waste time an-

alyzing benign materials in the sam-

ple. Integrated microscopy allows for

rapid search of large areas in a sample, target-

ing problem particles while disregarding empty space.

Scanning electron microscopy combined with

energy-dispersive x-ray spectroscopy (SEM/EDX)

provides efficient, accurate microanalysis that iden-

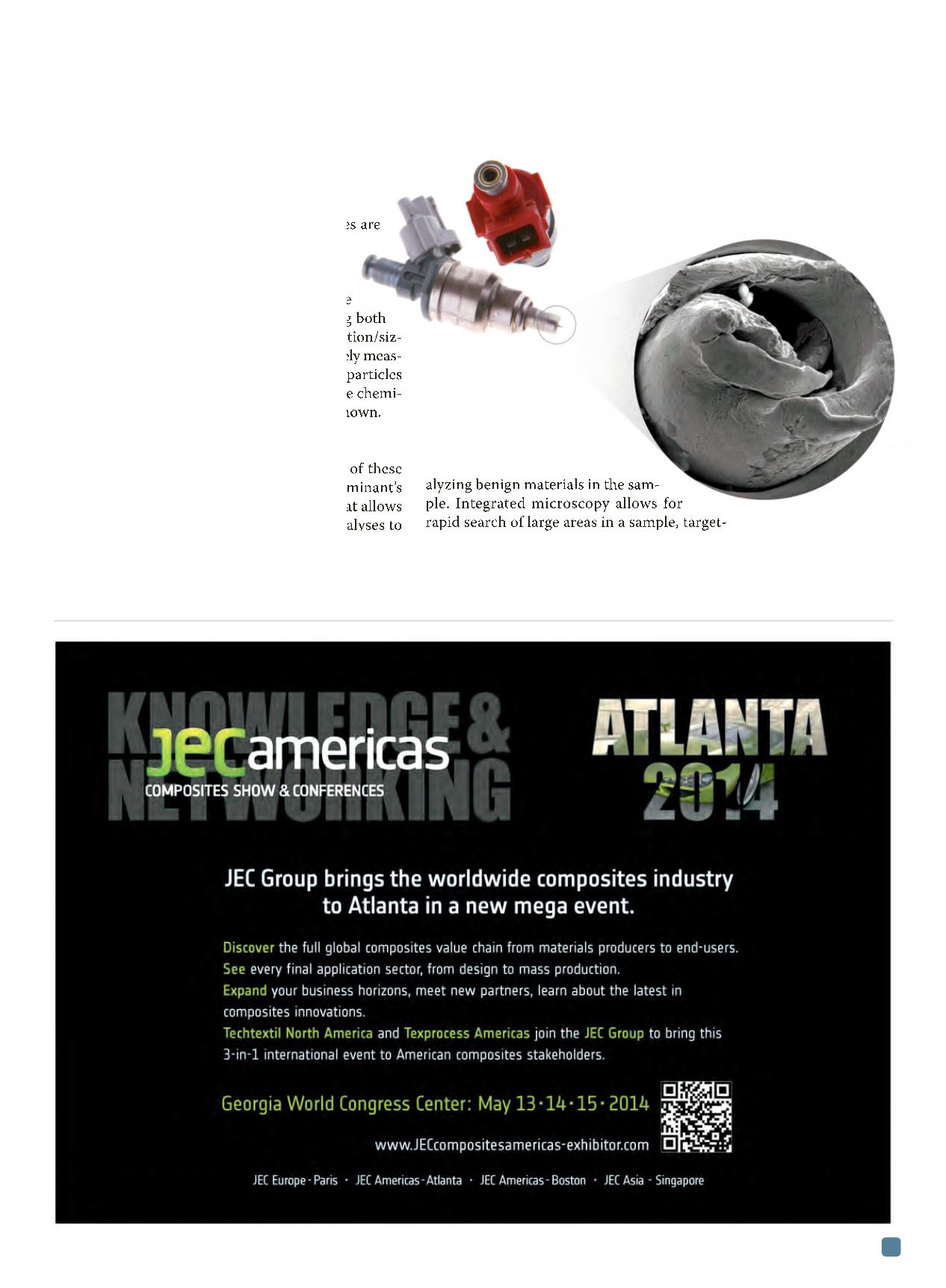

SEM image of a particle

lodged inside a fuel injector.