ADVANCED MATERIALS & PROCESSES •

MARCH 2014

30

tifies size, shape, and chemical compo-

sition of particles. Traditionally,

SEM/EDX required personnel to man-

age the instrument or interpret data.

One alternative, the CleanCHK Ana-

lyzer from FEI, Hillsboro, Ore., requires

little or no expertise to more effectively

monitor particle cleanliness by identify-

ing the source of even the smallest par-

ticle. The device monitors surface

cleanliness by automatically detecting

and counting particles, and analyzes

their size, shape, and composition

within minutes.

Designed for use on the production

line floor, the system can identify parti-

cles as small as 0.5 µm so that the source

of contaminants can be determined and

problems can be fixed right away. The

instrument allows automated sample

setup, analysis, and instrument calibra-

tion and provides accurate information

on particle size, shape, and chemistry.

Classifications can be selected and auto-

matically obtained based on the meas-

ured parameters.

100

m

m

100

m

m

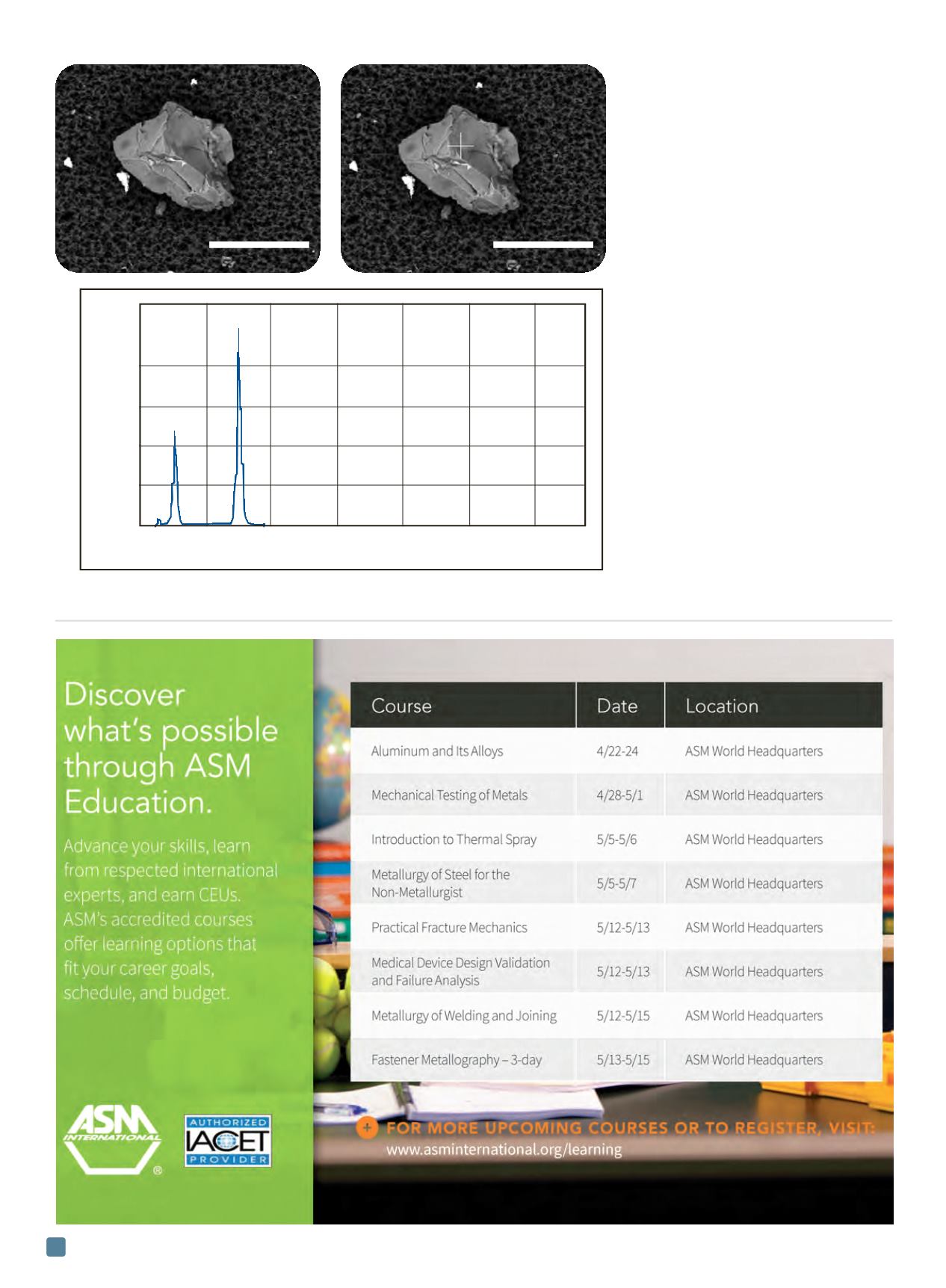

SEM image of aluminum oxide particle with corresponding EDS.

1 2 3 4 5 6

keV

2320

1740

1160

580

0

Al

O