ADVANCED MATERIALS & PROCESSES •

MARCH 2014

33

the latest developments in ordnance and armor

plate, he came into contact with the Bessemer steel-

making process. Bessemer had a pilot plant where

he was very busy in this period showing off his

process to interested parties. However, Holley real-

ized that the patent situation needed to be resolved

before the process could become commercialized in

the U.S. He accomplished this task and built the first

Bessemer steel plant in Troy, N.Y., in 1865.

In the meantime, the first successful steel made

by this process in the U.S. was cast at the little plant

in Wyandotte, Mich., at the Kelly Pneumatic Process

Company. An ASM historical marker pays tribute to

this event. Ingots from this heat were shipped to the

North Chicago Rolling Mill Company where they

were successfully rolled into the first steel rails made

in America.

Patent release paves way for steel industry

The release of the patent deadlock cleared the

way for the domestic steel industry and Holley was

the chief promoter and designer. He either con-

structed or consulted on nearly all 15 Bessemer

plants built by 1875. These included the very early

plant of the Pennsylvania Steel Company near Har-

risburg, with J. Edgar Thomson and Thomas Scott of

the Pennsylvania Railroad Company as principals;

the Cambria Steel Company where Kelly received

support fromMorrell to develop the process; the first

plant in Pittsburgh built for Andrew Carnegie and

named for his benefactor (J. Edgar Thomson, presi-

dent of the Pennsylvania Railroad); plants at North

Chicago and Joliet, Ill.; a plant for the Vulcan Works

at St. Louis, Mo.; and plants for Bethlehem Steel and

Scranton Steel in eastern Pa.

These early steel plants were small enterprises by

later comparisons. Bessemer converters had reached

only five tons by the early 1870s. Also, their supply

of molten metal typically came from remelting cast

iron in separate furnaces. At this stage in America’s

industrialization, mills simply were not equipped to

handle large quantities of molten metal.

For his contribution to the development of the

Kelly-Bessemer process, Alexander Holley has been

called the “Father of American Steelmaking.” He was

elected president of the American Institute of Mining

and Metallurgical Engineers as well as the American

Society of Mechanical Engineers, and named vice

president of the American Society of Civil Engineers.

After his death from peritonitis at age 49 in 1882,

these engineering societies commissioned a statue of

Holley that remains standing in Manhattan’s Wash-

ington Square Park. Engineers from all of the major

technical societies attended the dedication, includ-

ing members from France and Germany.

Future forward for U.S. steel

The U.S. was now positioned to experience an

even brighter future for iron and steel. During the last

30 years of the 19th century, production would in-

crease nearly tenfold for iron—from 1.7 million tons

in 1870 to 14 million tons in 1900—and for steel,

from 68,750 tons in 1870 to 10 million tons in 1900.

Throughout the 1890s, the U.S. produced one-third

of all the world’s steel, and half of that went into rail-

road rails.

Bessemer steel gradually became the material of

choice for rails and beams because it was stronger,

harder, and far more wear resistant for rails than

wrought iron. In the final analysis, however, it was

the much lower costs for manufacturing Bessemer

steel compared to wrought iron that tipped the scales

in its favor. In the 1890s, with competition high

among the mills, the price of steel for rails hit a low

of $11 per ton. Low-cost steel was the force behind

America’s modern industrial growth, and the major

force behind this growth was an immigrant Scotsman

named Andrew Carnegie.

For more

information:

Charles R. Simcoe

can be reached at

crsimcoe@yahoo.com.

For more metallurgical

history,

visit

www.metals- history.blogspot.com.

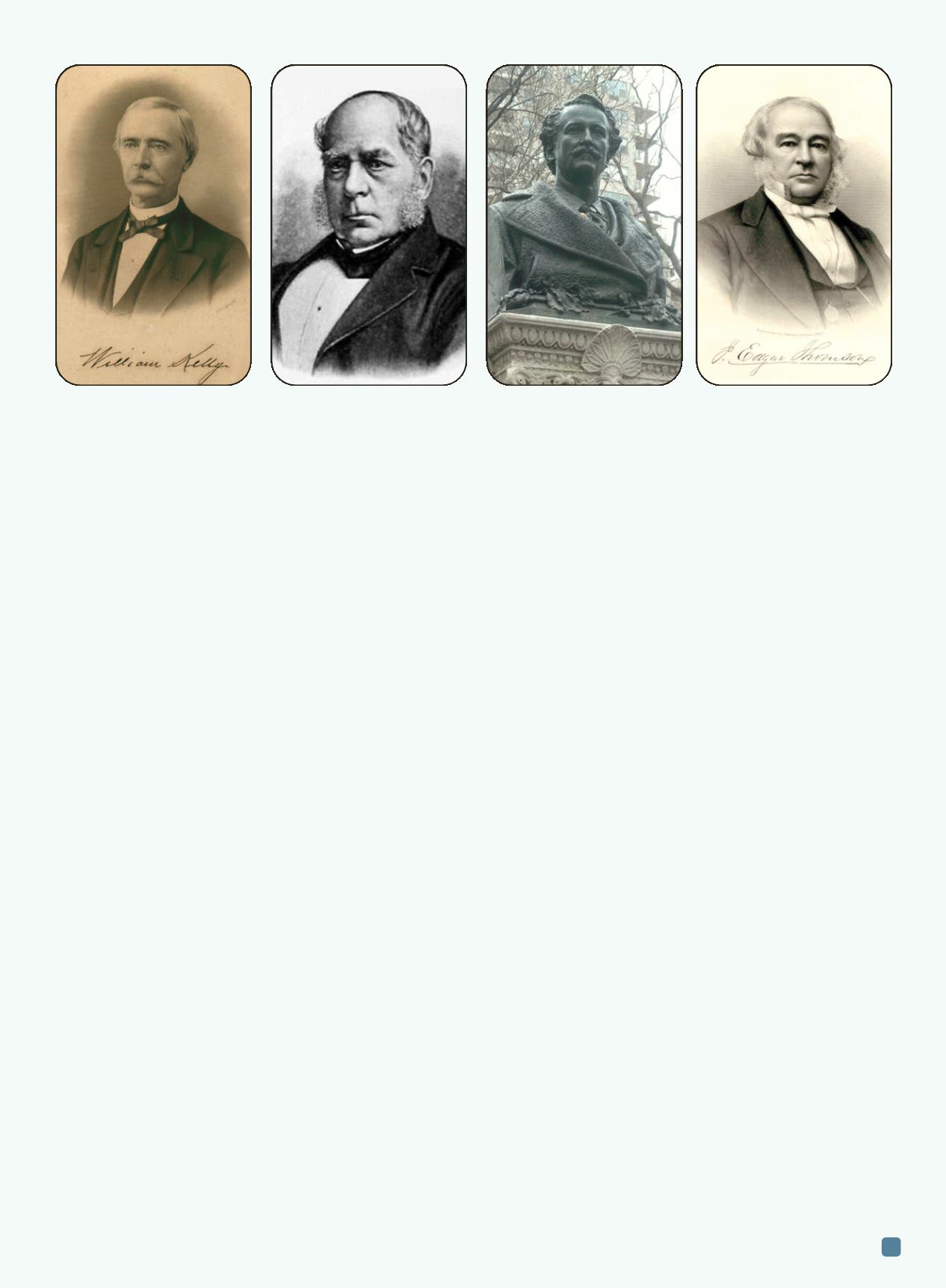

William Kelly was an American

metallurgist and inventor of a

process for refining pig iron, a

precursor of the Bessemer

converter.

Henry Bessemer—of Bessemer

process fame—was originally

working on a way to replace the

cast iron in cannons with steel.

The bust of Alexander Lyman

Holley stands in Manhattan’s

Washington Square Park.

J. Edgar Thomson, president of

the Pennsylvania Railroad.