ADVANCED MATERIALS & PROCESSES •

MARCH 2014

32

I

n the latter half of the 19th century, the indus-

trial world of wrought iron experienced a revolu-

tion: A process for making steel directly from

blast furnace cast iron was being developed at two

different locations. One was at a small iron mill in

Kentucky owned by two brothers—William and

John Kelly. As usual, the men soon encountered a

fuel shortage after clearing all the timber near the

plant for charcoal. With this in mind, William Kelly

noticed that the cold air was not chilling the metal,

but was reacting with it chemically to generate heat

where the air blast impinged on the molten metal

in the finery. Kelly immediately recognized the

value of this reaction as a means of converting pig

iron to wrought iron. Although this revelation oc-

curred in 1847, he was delayed in building a con-

verter until 1851.

The second location was in England where an

engineer and inventor named Henry Bessemer—

who had invented the artillery shell—was work-

ing on a way to replace the cast iron in cannons

with steel. Bessemer’s finances were much bet-

ter than Kelly’s, allowing him to pursue his ideas

immediately.

Kelly moved his experimental operations to the

Cambria Iron Company in Johnstown, Pa., the

company where Daniel Morrell and John Fritz were

laboring to develop their three-high mill to roll

wrought iron into rails. Kelly received his patent in

1857, just as a U.S. financial panic was taking hold,

and went bankrupt along with thousands of other

businessmen. He sold the controlling interest in his

patent in 1861, and two years later a company was

formed to produce steel by his process. This en-

tity—the Kelly Pneumatic Process Company—was

located in a pilot plant in Wyandotte, Mich., out-

side of Detroit. At this point, the operation devel-

oped the same quality problem that plagued

Bessemer in England.

During Bessemer’s experimental work, he had

fortuitously used Swedish ore, which was low in

impurities. Later, when his licensees were unable

to control the carbon content and make steel that

was not brittle, respected steelmaker Robert

Mushet showed that manganese was a necessary

ingredient to overcome the “hot shortness” caused

by sulfur. He also determined that carbon content

could only be controlled by blowing until it was

completely removed, and then adding back the re-

quired amount. By this time, German iron and

steelmakers had already developed a master alloy

called “spiegeleisen” for adding carbon and man-

ganese. Thus, Mushet was a major contributor to

the success of the so called Bessemer process.

However, the patent situation was now in gridlock

with Bessemer and Kelly each holding a vital posi-

tion in the process.

Bessemer process makes headway

During this period, America was in the throes

of the terrible war between the industrial north and

the agricultural, slaveholding south. Government

agents as well as private individuals from both

areas were combing Europe looking for armaments

and other developments that would aid their cause.

One such individual was a charismatic engineer

and technical writer by the name of Alexander

Lyman Holley.

Holley was born in Connecticut in 1832. He

graduated from Brown University in 1853 in the

first engineering class and started working on rail-

road locomotives. On a trip to Europe to observe

Metallurgy Lane,

authored by

ASM life member

Charles R. Simcoe

,

is a yearlong series

dedicated to the early

history of the U.S. metals

and materials industries

along with key

milestones and

developments.

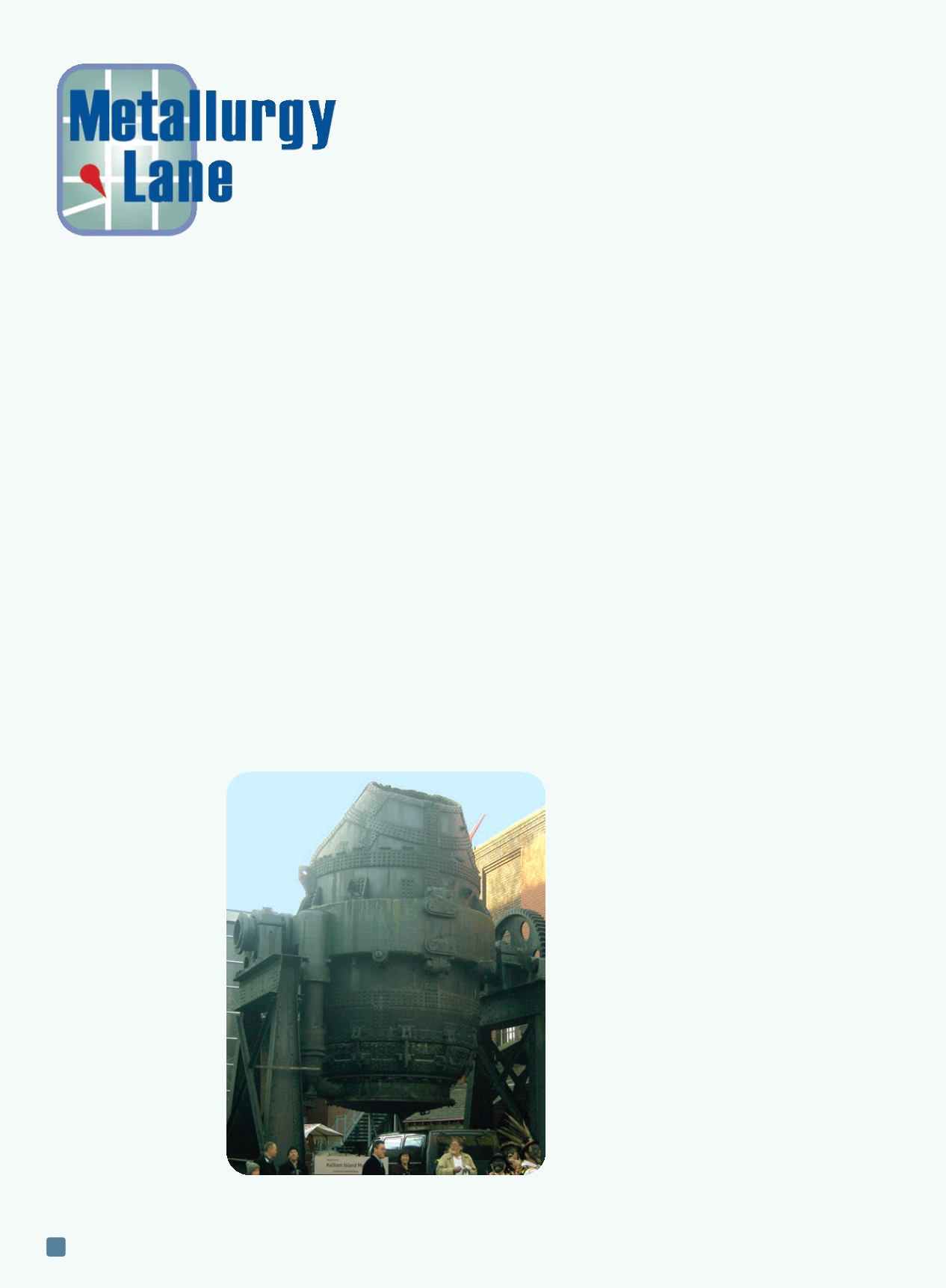

Bessemer converter at Kelham Island Museum,

Sheffield, England. Courtesy of Gunnar Larsson.

The Age of Steel: Part I

The second half of the 19th century set the stage for major U.S. industrial growth,

and the Bessemer steelmaking process played a significant role.