Laser Beam Texturing

for Automotive Metal Forming Applications

I

n the majority of metal drawing and forming

operations, a surface texture is applied to the

metal to aid forming. This surface texturing,

which is typically imparted as a matte finish,

primarily improves the metal’s drawability by

creating depressions in the surface and increas-

ing the lubrication carrying capacity. Addition-

ally, these types of textured finishes can

promote paint adhesion or enhance the appear-

ance of components.

In North America, most textured or matte

finishes are developed through either me-

chanical means (shot-blasting, grit-blasting,

grinding) or electro-discharge texturing

(EDT) of mill rolls that then impart the devel-

oped finish onto the metal surface during the

final rolling operation. Asia and Europe addi-

tionally use laser beam texturing (LBT) or

electron beam texturing (EBT) systems to in-

duce a matte finish on mill rolls. The finish

that these systems provide offers advantages

over more traditional methods. LBT materials

and how they differ from those produced

using traditional surface texturing techniques

will be discussed in this article.

Importance of matte/surface finishes

Lubrication is a critical factor in forming

and drawing flat rolled steels. Oil (the typical

lubricant) is applied to the surface to reduce

friction during forming and drawing. The sur-

face topography of steel impacts the lubri-

cant’s effectiveness during forming. The

matte or textured surface finish should be

consistent in surface characteristics across the

width as well as along the length to be effec-

tive. It should allow for even and consistent

contact pressure over the entire part, enhanc-

ing metal flow during forming and preventing

localized strains that could lead to failure.

Maintaining consistent lubrication greatly

reduces potential problems during forming and

drawing. Issues include:

• Die damage: Excessive die wear and/or

galling occurs due to localized strains,

increasing die maintenance costs.

• Product loss: Galling and damage to parts

can reduce yields and increase inspection

costs.

• Production delays: Extra time is needed to

service prematurely worn dies and to

make up for scrapped parts.

Advantages of

laser-beam-textured finishes

In order to adequately compare surface

characteristics of various types of finishes, it is

necessary to look beyond traditional profilome-

ter traces. While this information indicates sur-

face roughness and other parameters, each test

is a single trace across the surface. 3D imaging,

available through light interference technology,

allows for more refined analysis over a much

larger surface area, providing a more accurate

picture of the material’s topography. This tech-

nology plays a key role in quantifying the no-

table differences in the various types of matte

finishes detailed in this article.

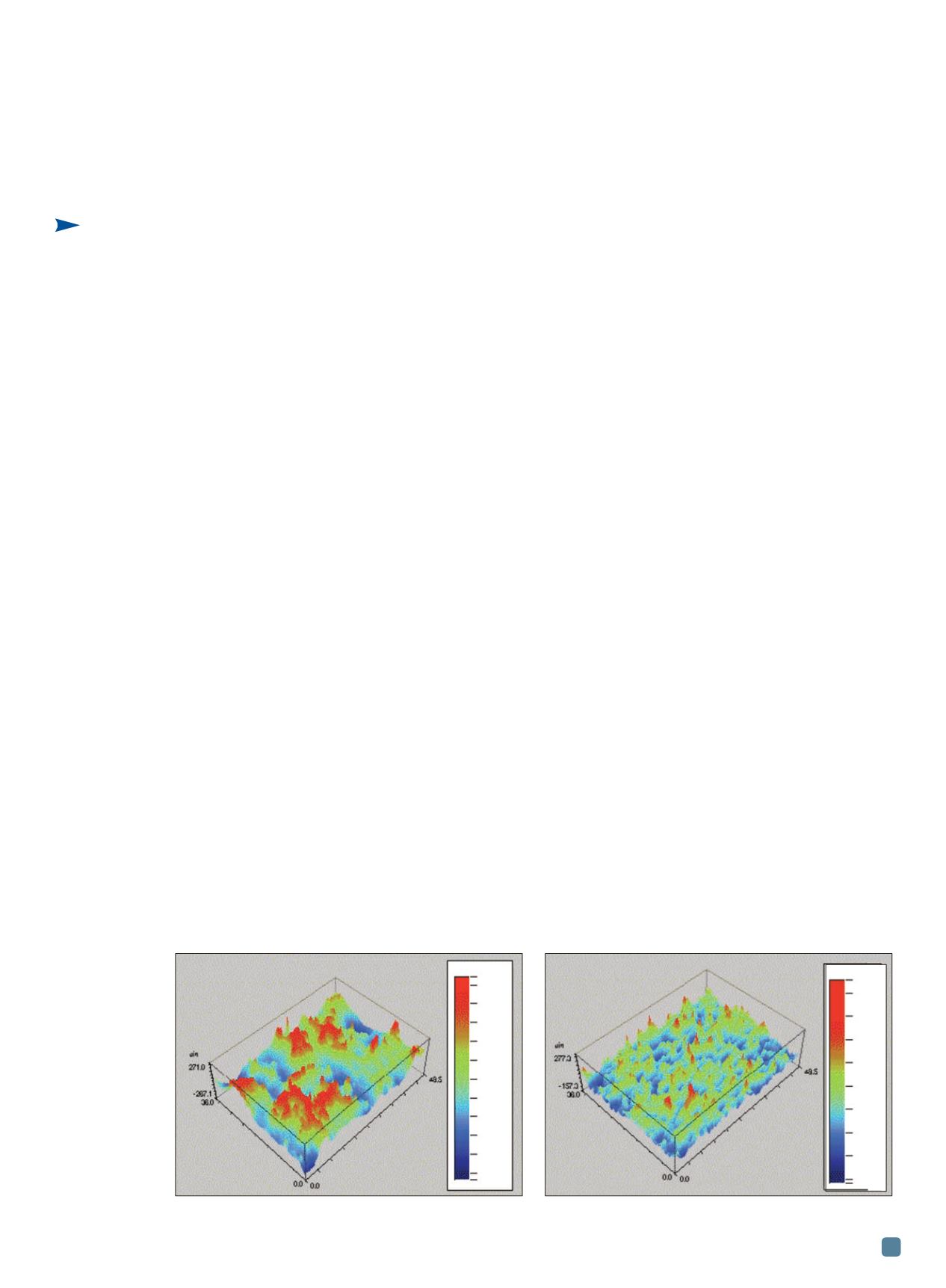

One common method, shot/grit-blasting,

propels abrasive media at the roll surface at

high speeds, which upsets the surface and pro-

duces a roughened texture or matte finish. This

method produces a somewhat nonuniform and

variable finish. Figure 1 shows the 3D surface

of steel produced from blasted finish mill rolls

as compared to the steel surface in Fig. 2, pro-

duced by EDT-processed mill rolls. EDT in-

volves applying a pulsed electric field between

Todd Daenzer

Greer Steel Co.

Dover, Ohio

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

25

An alternative

to traditional

surface

texturing

processes is

laser beam

texturing,

which offers

various

advantages

over other

commonly

used methods.

Fig. 1 –

Blasted surface finish in 3D.

Fig. 2 –

Electro-discharge textured surface in 3D.

uin

270.97

150.00

50.00

-50.00

-150.00

-267.11

uin

277.36

200.00

100.00

0.00

-157.31