Nondestructive Inspection of Resistance Spot Welds Using

Matrix Phased Array Ultrasonic Technology

A

dvanced high-strength steels (AHSS)

were introduced to the automotive in-

dustry to reduce vehicle weight and are

gaining momentum due to initiatives that call

for increased body rigidity (driving perform-

ance) and improved crash ratings and fuel effi-

ciency. One major challenge these steels

present involves the integrity of spot welds.

There are roughly 4000-7000 resistance spot

welds on every U.S.-made automobile and the

reliability of the body structure and passenger

safety both rely on sound welds.

The stress state at the weld, fracture tough-

ness of the weldment, and presence of pores,

cracks, and embrittled regions in AHSS are driv-

ing factors resulting in different failure modes

compared to conventional steels—particularly

interfacial type failures

[1]

. Traditional resistance

spot weld (RSW) destructive test methods such

as pry-bar or chisel check and peel tests are

costly and inaccurate when applied to welds

made from AHSS. The automotive industry

therefore seeks nondestructive tests to ensure

safe implementation of AHSS steels.

Some advanced nondestructive inspection

(NDI) techniques that may provide solutions

are already used in the aerospace and power

generation industries. Unfortunately, transfer-

ring these techniques to the automotive indus-

try is limited due to fundamental differences

[2]

.

The goal is to reduce the time to validate and

increase correlation methodology confidence

with less engineering and laboratory time. To

reduce the repeatability gap, improved robust-

ness of NDI techniques and little or no depend-

ence on operator skill is needed

[2]

.

MPA probe meets the challenge

Computational modeling and simulations

helped scientists develop a reliable, high-fre-

quency matrix phased array (MPA) probe with

an appropriate delay line and an optimal prop-

agation distance for the ultrasonic beam to be

focused on a spot weld. A commercially avail-

able CIVA modeling package was used to per-

form this modeling and simulation.

It was necessary to define parameters such

as material thickness and spot weld diameter.

Research revealed that the majority of spot

weld applications are for materials in the thick-

ness range of 0.7-2 mm having a nominal weld

diameter of 5-7 mm. Initial beammodeling cal-

culations helped determine general parameters

for a probe capable of inspecting spot welds in

the targeted range. Consideration was given to

current MPA instrumentation capabilities, al-

though many MPA instruments on the market

today limit the number of elements to a maxi-

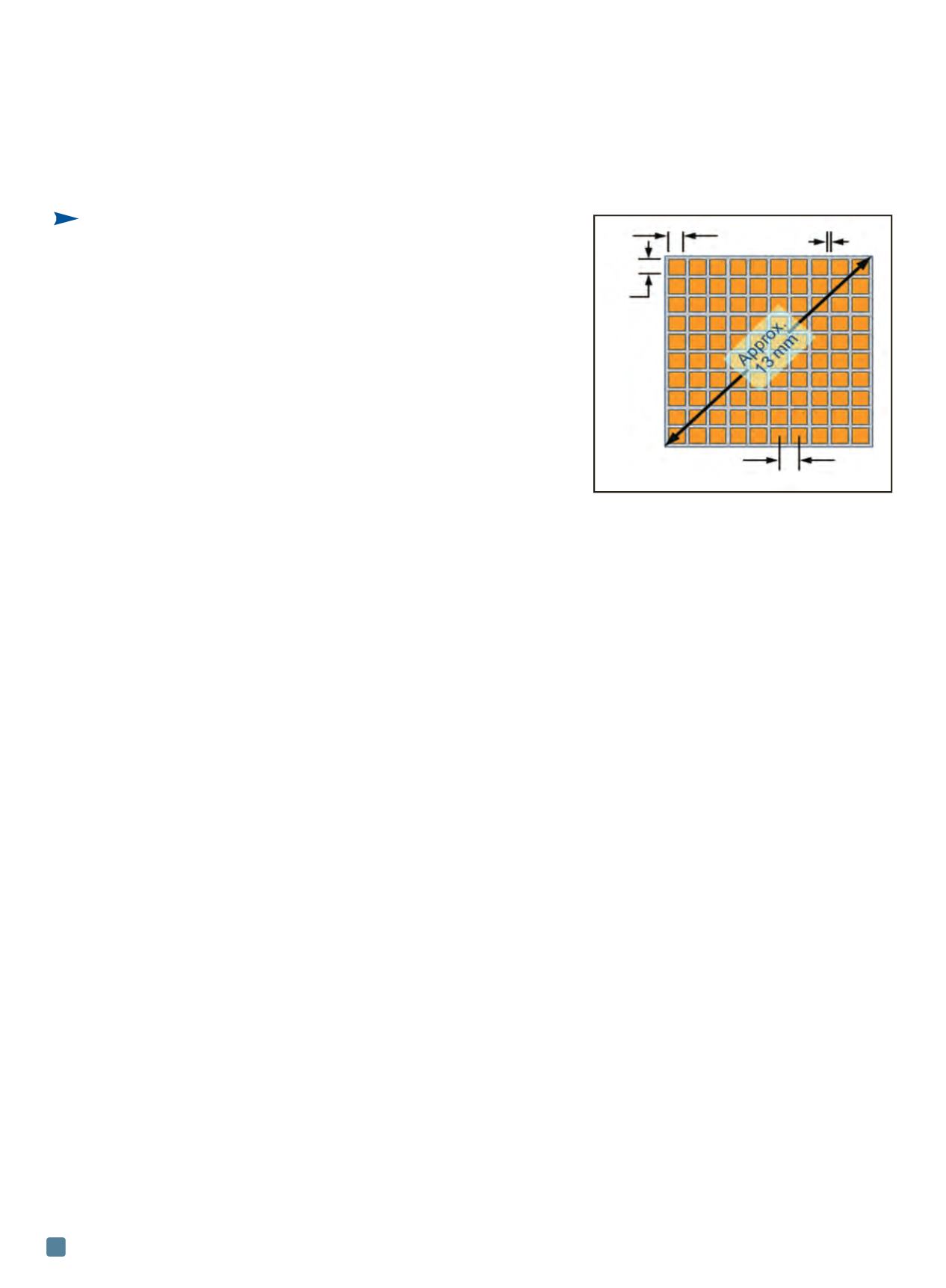

mum of 128. Figure 1 shows a schematic of a

100-element 2DMPA probe element with some

probe parameters evaluated using the beam

modeling tools. The same probe parameters

apply to 3D probes with additions of curvature

shape and radius.

To achieve good focus at a depth of 0.7-2

mm, the probe needs to have a physical delay

distance between the element and part surface.

The delay line tip was filled with water because

it conforms to surface deformations caused by

the welding electrodes. Modeling and simulation

results show that a water path length of 18 mm

produces a narrow beam with minimum side

lobes through the interface of water and metal.

A handheld probe was designed and fabri-

cated with an 18-mm-long water delay line cav-

ity at the end. Subsequent modeling

investigation for a 64-element probe with an

8×8 matrix configuration operating at a 12

MHz frequency proves the same water delay

line could be used. In this case, the probe ele-

ment was shaped to have a convex curvature

with a 50-mm radius.

From simulation to reality: Portable NDI

The EWI SpotSight inspection system

shown in Fig. 2 harnesses the power of MPA-

based ultrasonic imaging technology to accu-

rately evaluate the effectiveness of component

joints by showing weld nugget images in real-

Jeong K. Na

EWI

Columbus, Ohio

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

22

Automobile

performance

and passenger

safety both

rely on sound

welds. A new,

high-frequency

ultrasonic MPA

probe performs

nondestructive

inspection of

these welds,

saving time

and cost.

0.8 mm

0.1 mm

0.8

mm

0.9 mm pitch

Fig. 1 —

Schematic of a 2D matrix phased array

(MPA) probe element.