Inclusion removal

In addition to assessing the amount of inclusions in Mg

alloys, it is necessary to adapt suitable procedures and

techniques to remove them. Table 2 summarizes some sim-

ple techniques to remove inclusions from Mg alloys.

Historically, Mg melts were protected during melting

and casting using fluxes such as MgCl

2

, KCl, and CaF

2

[1]

.

While adequate at protecting Mg melts from oxidation,

fluxes can be entrapped in the melt during transfer and

casting and become inclusions. Since the 1970s, the Mg in-

dustry has largely used sulfur hexafluoride (SF

6

) to protect

Mg melts

[15]

. SF

6

modifies the magnesium oxide film that

forms naturally on the surface of the melt, thereby sup-

pressing vaporization. This compound is also attractive as

a cover gas because it is odorless, colorless, nontoxic, non-

flammable, and noncorrosive. However, SF

6

is becoming

increasingly expensive and is also an extremely powerful

greenhouse gas, with a 100-year global warming potential

(GWP), estimated at 23,900 times that of CO

2

[18]

. Nonreac-

tive gases, such as nitrogen and argon, prevent burning.

However, use of such gases is impractical outside of the

laboratory because they do not suppress Mg vaporization,

which can result in melt loss.

Even with adequate protection, high melt turbulence

increases the probability of entraining gases or oxide films

during mold filling, introducing more inclusions into the

casting. Incorporating filters into the casting process helps

reduce melt turbulence by regulating metal flow. Filters for

Mg alloys have typically been composed of ceramic (Al

2

O

3

,

SiO

2

, ZrO

2

, MgO, or a combination of these oxides) in a

foam-like structure with several open cells or as a steel

mesh. However, ceramic filters have controversial effi-

ciency because they may also react with the Mg melt.

Tardif, et al.

[16]

examined the use of knitted steel mesh fil-

ters to remove melt inclusions in permanent molds. Two-

and four-ply filter configurations entrap mostly MgO and

some Al-Mn-Fe intermetallic particles. Griffiths and Lai

[9]

observed that ceramic filters in combination with a well

designed gating system could reduce double oxide film de-

fects. Filtration is a simple and effective method for remov-

ing inclusions in Mg melts, but more research is needed to

optimize performance and understand the best methods

to incorporate filters with the gating system.

Filtration can be combined with inert gas bubbling to

further improve inclusion removal. Inert gas bubbling uses

Ar or CO

2

to float melt inclusions to the melt surface

where they can be skimmed away. The efficiency of gas

bubbling to remove inclusions depends on bubbling time,

gas flow rate, bubble size, and melt temperature

[19]

. Typical

usage of Ar gas bubbling for 6 kg of AZ91D involves a flow

rate of 1.8 l/min at a melt temperature of 740°C for a bub-

bling time of 30 minutes

[19]

. The limited availability of

quantitative results on gas bubbling efficiency has sparked

the need to determine optimal processing variables (e.g.,

Ar flow rate, residence time, bubble diameter, melt tem-

perature) to enable efficient melt refining. A steel mesh fil-

ter with Ar bubbling treatment was as effective as

degassing to improve mechanical properties and did not

release harmful hydrocarbons when added to the melt

[20]

.

Melt degassing typically uses reactive chlorine (Cl

2

)

gas or hexachloroethane (C

2

Cl

6

) to reduce hydrogen gas

content within melts. Both methods promote formation

of MgCl

2

, which can remove inclusions but may become

an inclusion itself if it becomes entrapped in the melt.

Adding C

2

Cl

6

could reduce grain size in castings, but

causes environmental problems due to chlorinated hy-

drocarbon emissions

[17]

.

Effects of inclusions on Mg casting properties

The influence of inclusions on mechanical properties

(strength and elongation), machinability, corrosion resist-

ance, and fluidity is demonstrated in Fig. 4. The presence

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

18

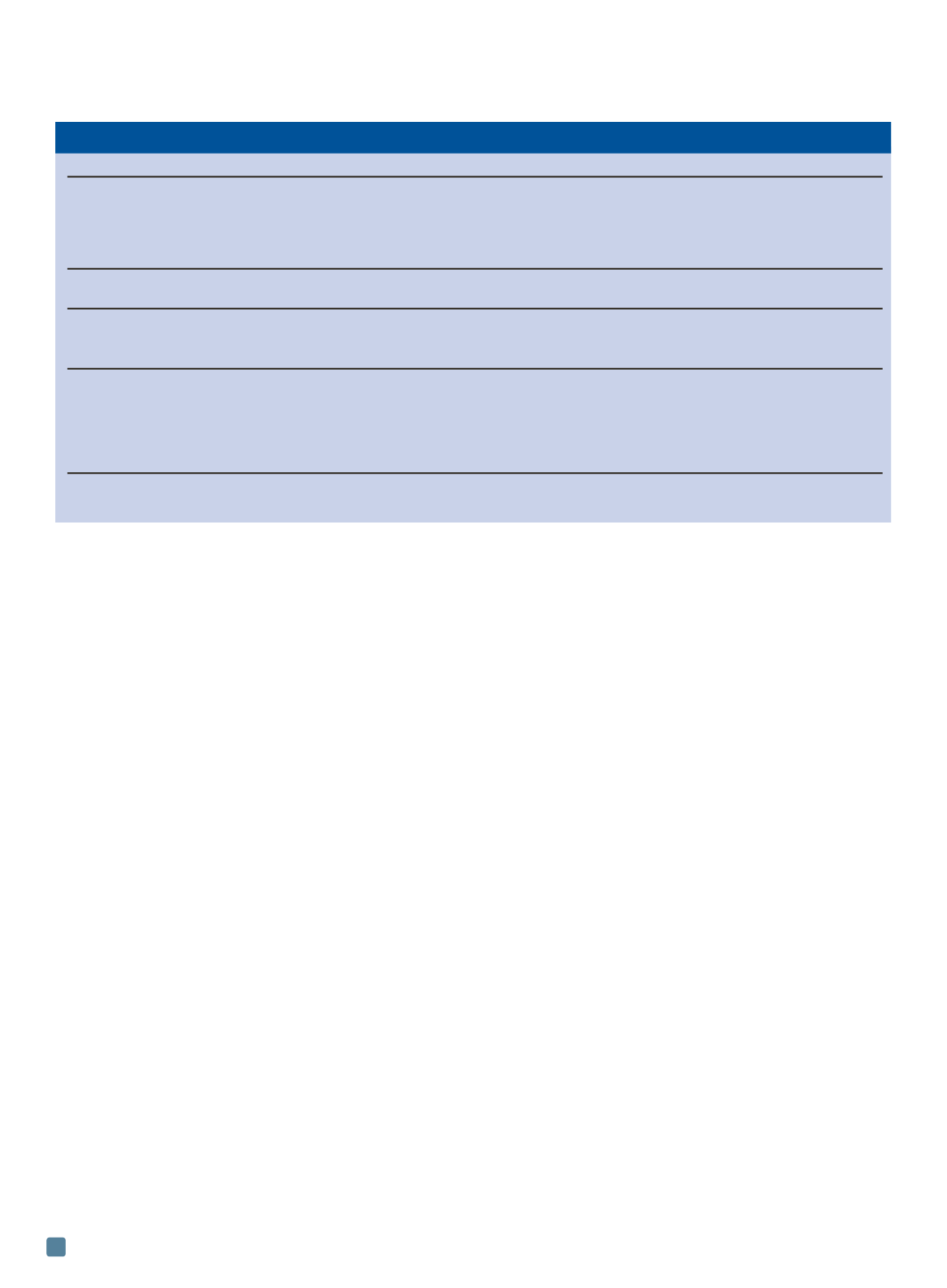

TABLE 2 — SUMMARY OF METHODS TO REMOVE INCLUSIONS IN Mg ALLOYS

Process

Description

Advantages

Disadvantages

Flux refining

MgCl

2

, KCl, NaCl and

Simple and cost effective

Flux may become entrapped

CaF

2

based

[1]

in melt

Flux absorbs oxides to produce

Flux compositions must be

a sludge that settles to the

tailored to alloy being melted

bottom of the crucible

Protective

SF

6

forms a dense film of

Very effective even at

Potent greenhouse gas

atmosphere (SF

6

)

MgO and MgF

2

[15]

0.1-0.2 vol.%

Filtration

Ceramic foam and steel

Can entrap MgO bifilms

[9]

,

Must be incorporated into

mesh types

particles and some Al-Mn-Fe

mold/casting design

Placed in mold cavity

intermetallics

[16]

Inert gas

Ar or CO

2

gas is used to float

Can be combined with

Large inclusions cannot

bubbling

inclusions to the melt surface

filtration

be removed

for skimming

Low purity gases or moisture

Can introduce porosity

Efficiency depends on bubbling can introduce more inclusions

Optimization of parameters

time, gas flowrate, bubble

size and melt temperature

required

Degassing

Cl

2

gas or C

2

Cl

6

Very effective

Releases toxic chlorinated

Formation of MgCl

2

(flux)

hydrocarbons

[17]