news

industry

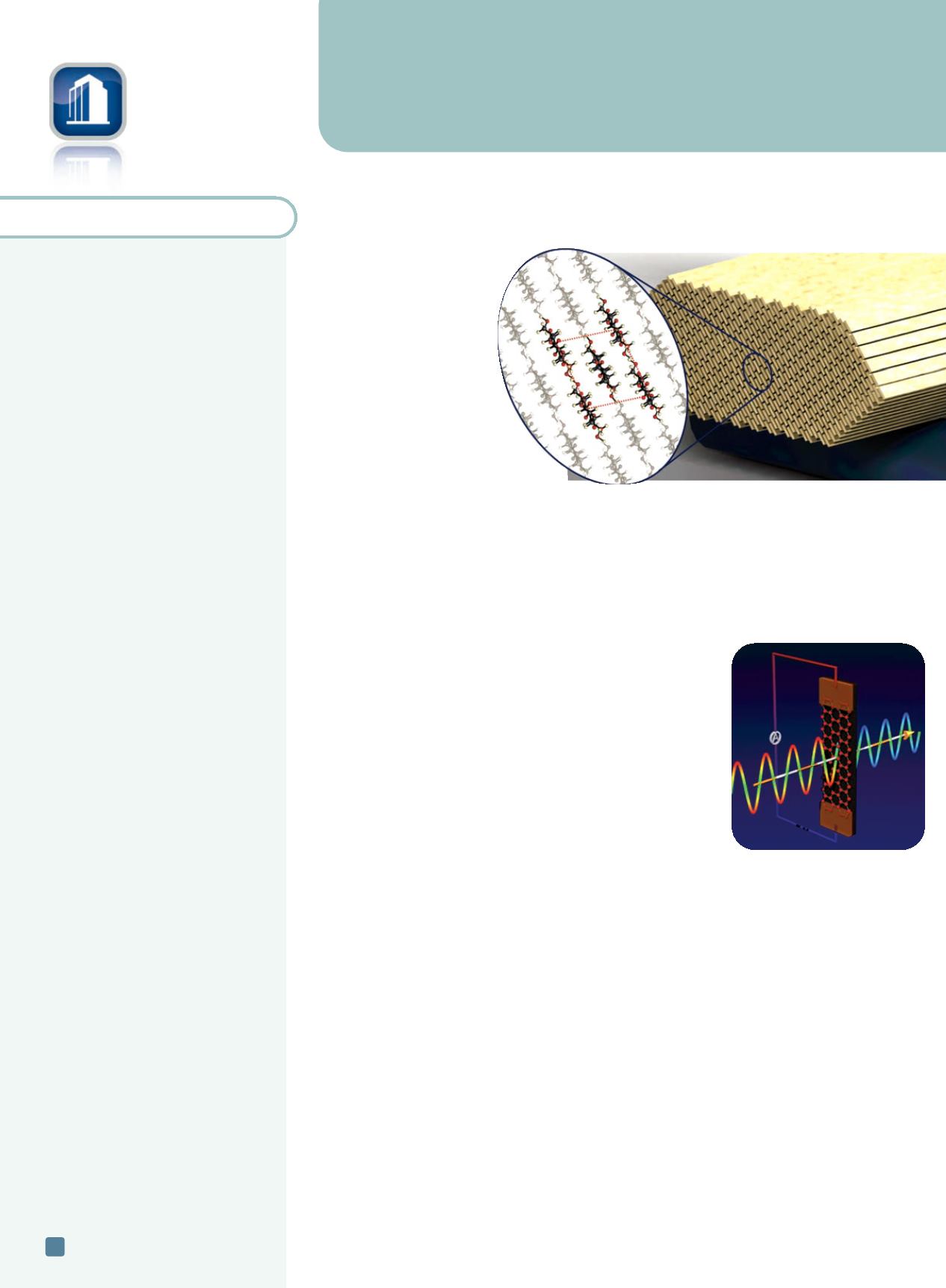

Cellulose nanocrystals potential wonder material

The same tiny cellulose crystals that give trees and plants

their high strength, light

weight, and resilience were

shown to have the stiffness

of steel, according to re-

search at Purdue Univer-

sity, West Lafayette, Ind.

Calculations using precise

models based on the

atomic structure of cellu-

lose show the crystals have

a stiffness of 206 gigapascals,

which is comparable to steel,

according to Pablo Zavattieri, as-

sistant professor of civil engineering.

“This is a material that is showing really

amazing properties,” he explains. “It is abundant, re-

newable, and produced as waste in the paper indus-

try.” The nanocrystals are about 3 nm wide by 500 nm long, making them too small to

study with light microscopes and difficult to measure with laboratory instruments. They

represent a potential green alternative to carbon nanotubes for reinforcing materials such

as polymers and concrete.

For more information: Pablo Zavattieri,

zavattie@purdue.edu,

https://engineering.purdue.edu.

New de-icer is light and inexpensive

Ribbons of ultrathin graphene combined with

polyurethane paint meant for cars are just right for de-icing

sensitive military radar domes, according to scientists at Rice

University, Houston. The researchers, in collaboration with

Lockheed Martin, developed the compound to protect ma-

rine and airborne radars with a robust coating that is also

transparent to radio frequencies. Because graphene is so thin,

it allows radio frequencies to pass through bulky radar domes

(radomes) unhindered. Radomes are used on military ships to

keep ice and freezing rain from forming directly on antennas.

Spray-on de-icing material that incorporates graphene

nanoribbons would be lighter, less expensive, and more ef-

fective than current methods, according to researchers.

www.rice.edu,

www.lockheedmartin.com.

Grant helps nanoparticle manufacturing

Making large quantities of reliable, inexpensive nanopar-

ticles for batteries, solar cells, catalysts, and other energy ap-

plications has proven challenging due to manufacturing

limits. A Cornell University, Ithaca, N.Y., research team is working to improve such

processes with a $1.5 million National Science Foundation (NSF) grant to support scala-

ble nanomanufacturing and device integration. Richard Robinson, assistant professor of

materials science and engineering, and Tobias Hanrath, associate professor of chemical

and biomolecular engineering, received a four-year Nanoscale Interdisciplinary Research

Team grant through the NSF’s Scalable Nanomanufacturing Program. Their goal is to im-

prove large-scale, solution-phase synthesis of high-quality nanoparticles—in particular

metal sulfides—and demonstrate their integration into devices including battery electrodes

and solar photovoltaics.

www.cornell.edu.

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

14

N

ANOTECHNOLOGY

briefs

A new microscope invented at

Michigan State University,

East

Lansing, allows scientists to zoom

in on the movements of atoms and

molecules. An associate professor

of physics and astronomy brought

“molecular movies” down to the

nanoscale level, where the

properties of materials begin to

change. The work has applications

in nanoelectronic technologies and

clean-energy industries. The team

is said to be one of the few in the

world actively developing electron-

based imaging technology on the

femtosecond timescale.

www.msu.edu.

Researchers at

Florida State

University,

Tallahassee, received

more than $1.4 million from the

National Science Foundation to

develop a system that will produce

large amounts of a state-of-the-art

material made from carbon

nanotubes that researchers believe

could transform everything from

the way airplanes are built to how

prosthetic limbs fit the human

body. The material, buckypaper, is

a featherweight sheet made of

carbon nanotubes that is being

tested in the electronics, energy,

medicine, space, and

transportation industries.

www.fsu.edu.

The frictional characteristics of

nanotextured surfaces cannot be

fully described by the framework of

Amontons’ laws of friction,

according to new research from

the

University of Bristol,

UK.

Using a nanosized atomic force

microscope tip to scan across a

nanodomed surface, researchers

revealed sustained stick-slip

frictional instabilities under the

velocity and load regimes they

studied. A linear dependence

between the amplitude of these

frictional oscillations and the

applied load was found, leading to

the definition of the slope as the

stick-slip amplitude coefficient.

www.bris.ac.uk.

A new compound created

by Rice University and

Lockheed Martin provides

a thin, robust ice-melting

coating for marine,

airborne, and other uses.

The active element

consists of carbon

nanotubes “unzipped” into

ribbons. Courtesy of the

Tour Group.

Illustration depicts structural details of

cellulose nanocrystals. Courtesy of

Purdue University/Pablo Zavattieri.