news

industry

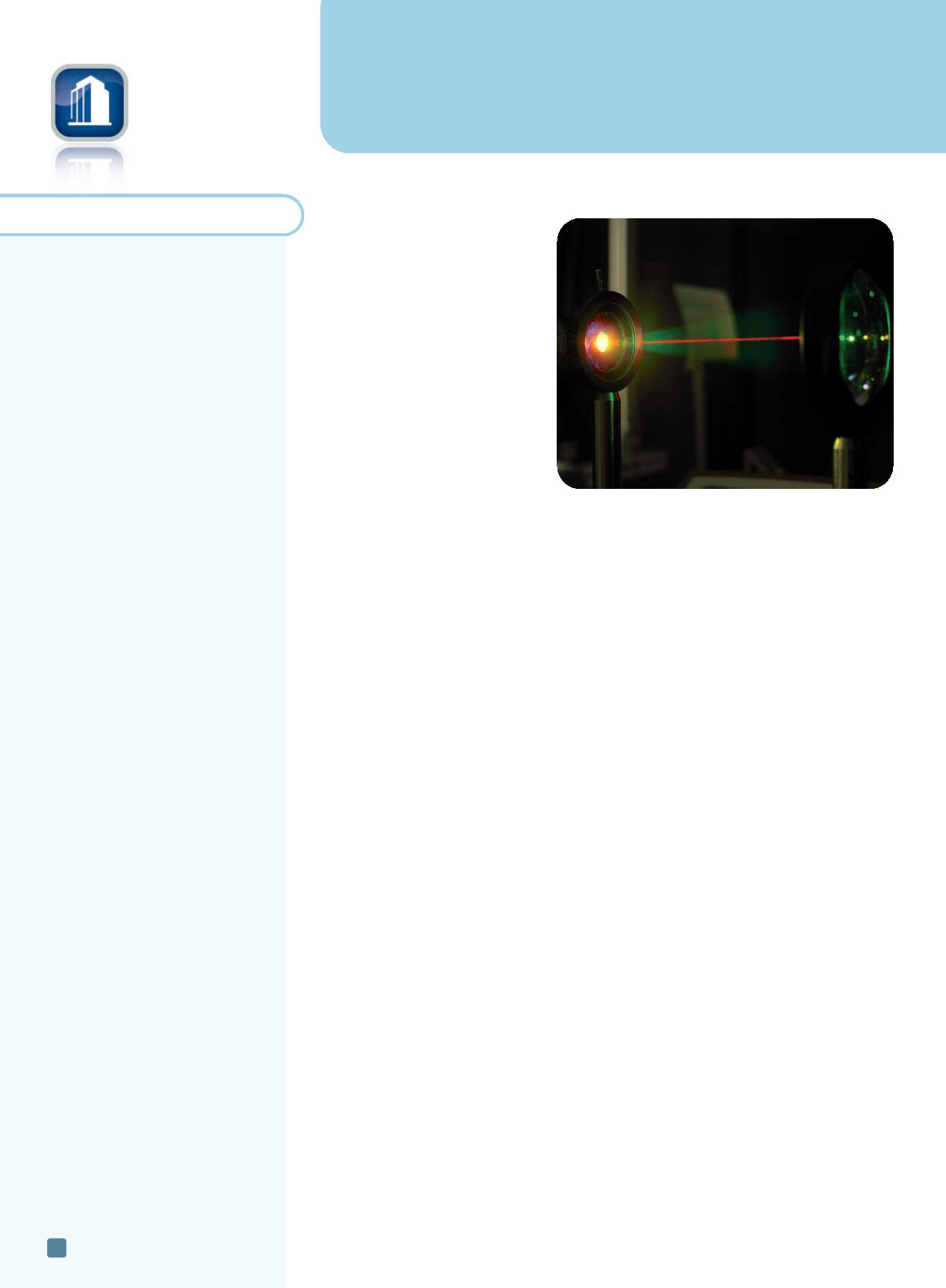

Silicon devices respond to infrared light

A new system developed by

researchers at five institutions, in-

cluding Massachusetts Institute

of Technology, Cambridge, cre-

ates detectors that are responsive

to a broad range of infrared light.

Silicon normally lets most in-

frared light pass through. The

new system works at room tem-

perature and provides a broad in-

frared response, say researchers.

It incorporates atoms of gold into

the surface of silicon’s crystal

structure in a way that maintains

the material’s original structure. It

also has the advantage of using

silicon, a common semiconductor

that is relatively low cost, easy to

process, and abundant. The approach works by implanting gold into the top hundred

nanometers of silicon and then using a laser to melt the surface for a few nanoseconds.

The silicon atoms recrystallize into a near-perfect lattice, and the gold atoms do not have

time to escape before getting trapped in the lattice.

For more information: Tonio Buonas-

sisi, 617/324-5130,

buonassisi@mit.edu,

www.web.mit.edu.

Increasing domestic plastic production

Low U.S. natural gas prices are helping increase domestic plastic production after a de-

cline from the 2008 recession. Because many U.S. plastic manufacturers use natural gas as

their primary fuel source and natural gas-sourced liquids as a feedstock, continued low

prices for those resources could boost raw plastic exports, given higher foreign energy

prices. During the economic downturn in 2008 and 2009, U.S. production of plastic prod-

ucts declined further than raw plastic production and has been slower to recover. Demand

for raw plastic from other parts of the world, such as China, remained strong, keeping U.S.

plastic resin production from falling further and enabling it to recover faster. Given the in-

expensive and versatile nature of polyethylene and polypropylene plastics, demand for

these materials has grown rapidly since the late 1990s, both domestically and abroad.

www.eia.gov.Self-healing battery electrode

Researchers made the first battery electrode that heals itself, opening a new and poten-

tially commercially viable path for making the next generation of lithium ion batteries for

electric cars, cell phones, and other devices. The secret is a stretchy polymer that coats the

electrode, binds it together, and spontaneously heals tiny cracks that develop during bat-

tery operation, according to the team from Stanford University and DOE’s SLAC National

Accelerator Laboratory, both in California.

Chao Wang, a researcher at Stanford, developed the self-healing polymer in the lab

of Zhenan Bao, whose group has been working on flexible electronic skin for use in

robots, sensors, prosthetic limbs, and other applications. For the battery project, he

added tiny nanoparticles of carbon to the polymer so it would conduct electricity.

“We found that silicon electrodes lasted 10 times longer when coated with the self-

healing polymer, which repaired any cracks within just a few hours,” explains Bao.

The electrodes worked for about 100 charge-discharge cycles without significantly

losing their energy storage capacity.

For more information: Zhenan Bao, 650/723-2419,

zbao@stanford.edu,

http://baogroup.stanford.edu.

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

12

E

NERGY

T

RENDS

briefs

Researchers at

Kansas State

University,

Manhattan,

demonstrated that a composite

paper—made of interleaved

molybdenum disulfide and

graphene nanosheets—can be

both an active material to

efficiently store sodium atoms and

a flexible current collector. The

newly developed composite paper

can be used as a negative

electrode in sodium-ion batteries.

Synthesis of large quantities of

single or few-layer-thick 2D

materials is crucial to

understanding the commercial

potential of materials such as

transition metal dichalcogenides

and graphene.

www.k-state.edu.

Researchers at the

University of

Cambridge,

UK, developed a new

method to probe silicon batteries

and determined what causes

silicon expansion, which degrades

battery performance, to take place.

Using nanoscale wires made of

silicon and nuclear magnetic

resonance techniques, a robust

model system able to

accommodate the expansion of the

silicon over multiple cycles was

developed and integrated with

short-range probing techniques,

which reveal what is happening

inside the battery at the atomic

level.

www.cam.ac.uk.

Researchers at the

University of

Liverpool,

UK, are investigating

the use of ultraviolet light to create

thin films that can be used on

solar panels. Funding from the

Engineering and Physical Sciences

Research Council (EPSRC) will

enable the scientists to develop

new methods for atomic layer

deposition using light rather than

heat to create the layers. The

project will replace the use of heat

from below with light from above

in order to create the reaction. This

is significantly more energy

efficient and will allow industry to

use atomic layer deposition in

many more applications that

require larger surfaces to be

covered.

www.liv.ac.uk.

A laser beam is used in the lab to test the gold-

hyperdoped sample of silicon to confirm its infrared-

sensitive properties. Courtesy of the researchers.