ment of the mold before solidification is complete can pro-

mote oxide entrapment.

Casting —

This process usually leads to melt turbulence

to a degree dependent on the pouring technique and gating

system. During casting, melt turbulence caused by poor

gating design is generally associated with high surface tur-

bulence and greater entrainment of oxide films. Entrained

oxides are typically double oxide film defects (bifilms) com-

prised of folded MgO films

[9]

. A fresh melt surface is also

exposed to the atmosphere, further increasing the possibil-

ity of inclusions being entrained within the melt.

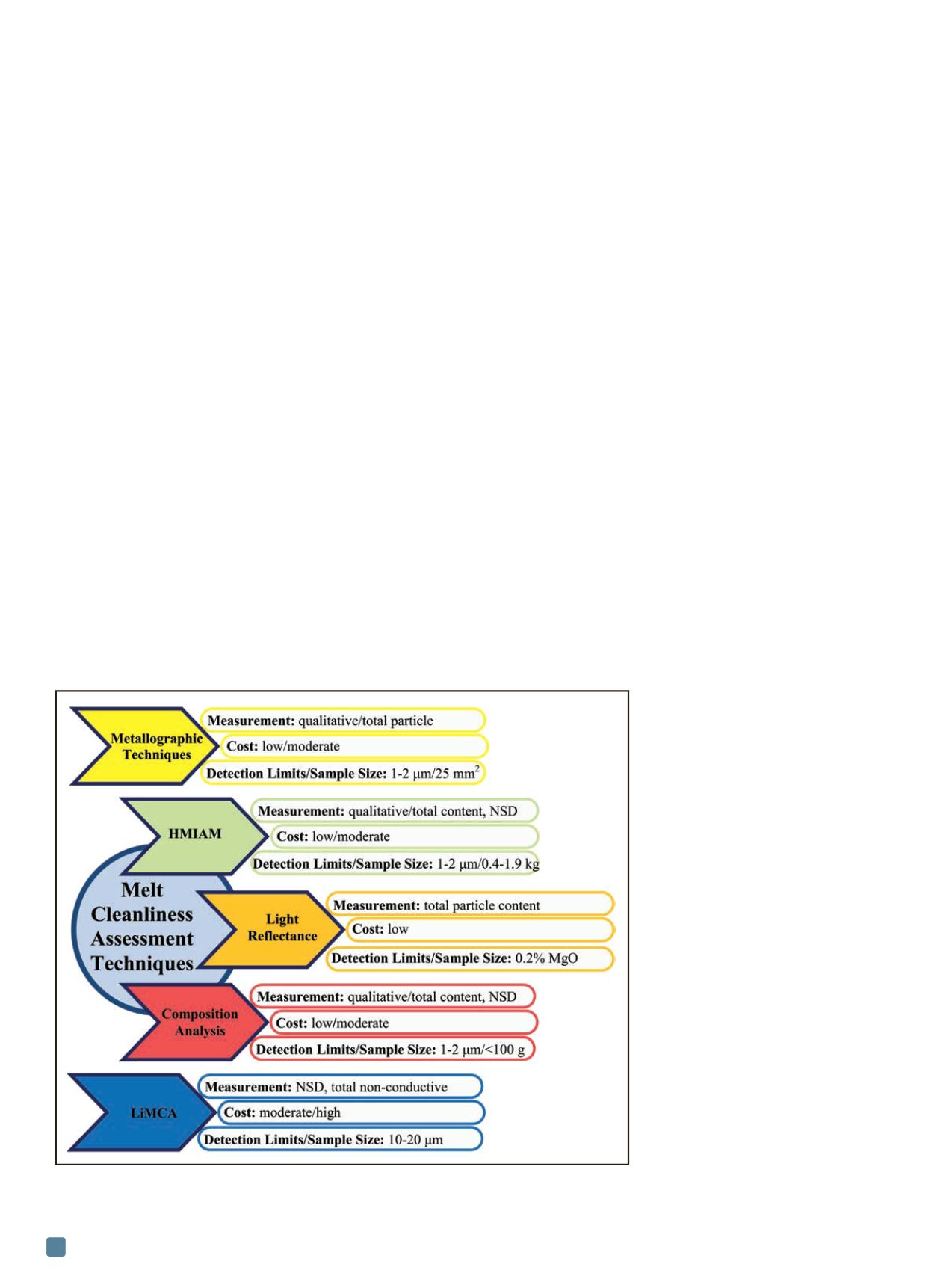

Assessment of inclusions in Mg alloys

A summary of methods used or considered to assess

metal cleanliness in the Mg industry is shown in Fig. 1, al-

though none of these methods are considered standard for

determining Mg melt cleanliness. Leading inclusion assess-

ment techniques include:

Metallographic techniques —

This relatively simple

method uses a sectioned sample of the cast product,

which is ground, polished, and examined using metallo-

graphic techniques. Metallography is usually combined

with image analysis to determine particle shape, size,

number, and distribution, or with scanning electron mi-

croscopy (SEM) and energy dispersive x-ray spectroscopy

(EDS) to determine the nature of inclusions and possible

sources of melt contamination

[12]

. Drawbacks associated

with classic metallographic techniques include small sam-

ple sizes, which may not be representative of the entire

casting, and the fact that inclusion content measurements

are done “offline” after the casting has been produced.

HMIAM —

With the hydro magnesium inclusion as-

sessment method (HMIAM), a known volume of the melt

is drawn through a stainless steel filter by vacuum. Inclu-

sions accumulate within or on top of the filter. Once the

melt has solidified and cooled, the filter and its contents

are sectioned parallel to flow direction and examined with

an optical microscope. The amount of inclusions in the

melt is measured as the volume of particles per unit weight

of metal drawn through the filter. Unlike metallographic

techniques, HMIAM is performed “online”

[7, 8]

. One disad-

vantage to this method is that the quantity and morphol-

ogy of oxides in ingots or die cast components may be

different from those observed on the filter due to a differ-

ent melt temperature

[10]

.

Light reflectance —

This technique is based on differ-

ences in optical characteristics between Mg and MgO and

involves fracturing a gravity cast sample and examining it

under the aperture of a brightimeter. The sample is illumi-

nated at a 45° angle to the fracture surface and reflected

light intensity is measured. Because inclusions have differ-

ent optical properties compared to the matrix, incident

light will be scattered at the specimen surface due to mul-

tiple reflections and refractions. In Mg alloys, MgO inclu-

sions absorb more light than the matrix, and as a result,

specimen reflectance is reduced. The reflectance should

therefore correlate with the oxide inclusion content in the

specimen

[11]

. However, this technique, while simple and in-

expensive, is unable to distinguish between different inclu-

sion types and sizes

[7, 10]

. Both HMIAM and light reflectance

techniques are shown in Fig. 2.

LiMCA —

The liquid metal clean-

liness analyzer (LiMCA) instrument

offers online measurement of noncon-

ducting particles as shown in Fig. 3.

The unit includes a probe, current

source, and signal processing system.

The probe consists of two electrodes

and an electrically insulating sampling

tube with an orifice through its sur-

face. Molten metal is drawn through

the aperture in the presence of a large

dc current. Nonconducting inclusions

as small as 20 μm are detected by

measuring the change in electrical

conductivity as they pass through the

aperture

[8]

. However, because this

technique operates by detecting

changes in electrical conductivity, it

cannot detect conductive inclusions

such as intermetallic particles and fails

to provide information on the chem-

istry, shape, or physical state of the in-

clusions. There are also difficulties in

finding appropriate nonconductive

materials for sampling tubes that are

nonreactive with Mg alloys, and equip-

ment cost is high as well

[8]

.

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

16

Fig. 1 —

Methods for inclusion assessment used or considered for use in the Mg industry

[6-8, 10-12]

.

HMIAM—hydro magnesium inclusion assessment method; LiMCA—liquid metal cleanliness

analyzer; NSD—number size distributions.