ADVANCED MATERIALS & PROCESSES •

MARCH 2014

15

Finding and Removing Inclusions in

Magnesium Alloys

M

agnesium and its alloys are among

the most promising lightweight ma-

terials. With a density of 1.74 g/cm

3[1]

(35% lighter than aluminum), Mg alloys are at-

tractive to both the aerospace and automotive

industries due to their high strength-to-weight

ratio, good castability, high impact resistance,

and high recyclability.

However, its high oxidation potential usu-

ally results in inclusion contents much greater

than that found in Al. Unlike Al alloys, which

form a stable nonporous oxide surface, molten

Mg produces a porous magnesium oxide

(MgO) surface that does not protect the molten

metal from further oxidation unless special pre-

cautions are taken. Inclusions in Mg alloys re-

duce strength and ductility, are detrimental to

surface finish, increase porosity, and exhibit a

tendency to increase corrosion

[2]

. Improving

the melt quality by controlling trace elements,

reducing the amount of dissolved gases, and re-

moving inclusions could enhance the proper-

ties of Mg and its alloys.

This article provides an overview of typical

inclusions found in Mg and its alloys, various

techniques used to determine inclusion con-

tent, and methods employed to reduce inclu-

sions and their influence on properties. This

discussion is based on a recent review article

on inclusions in Mg alloys

[3]

.

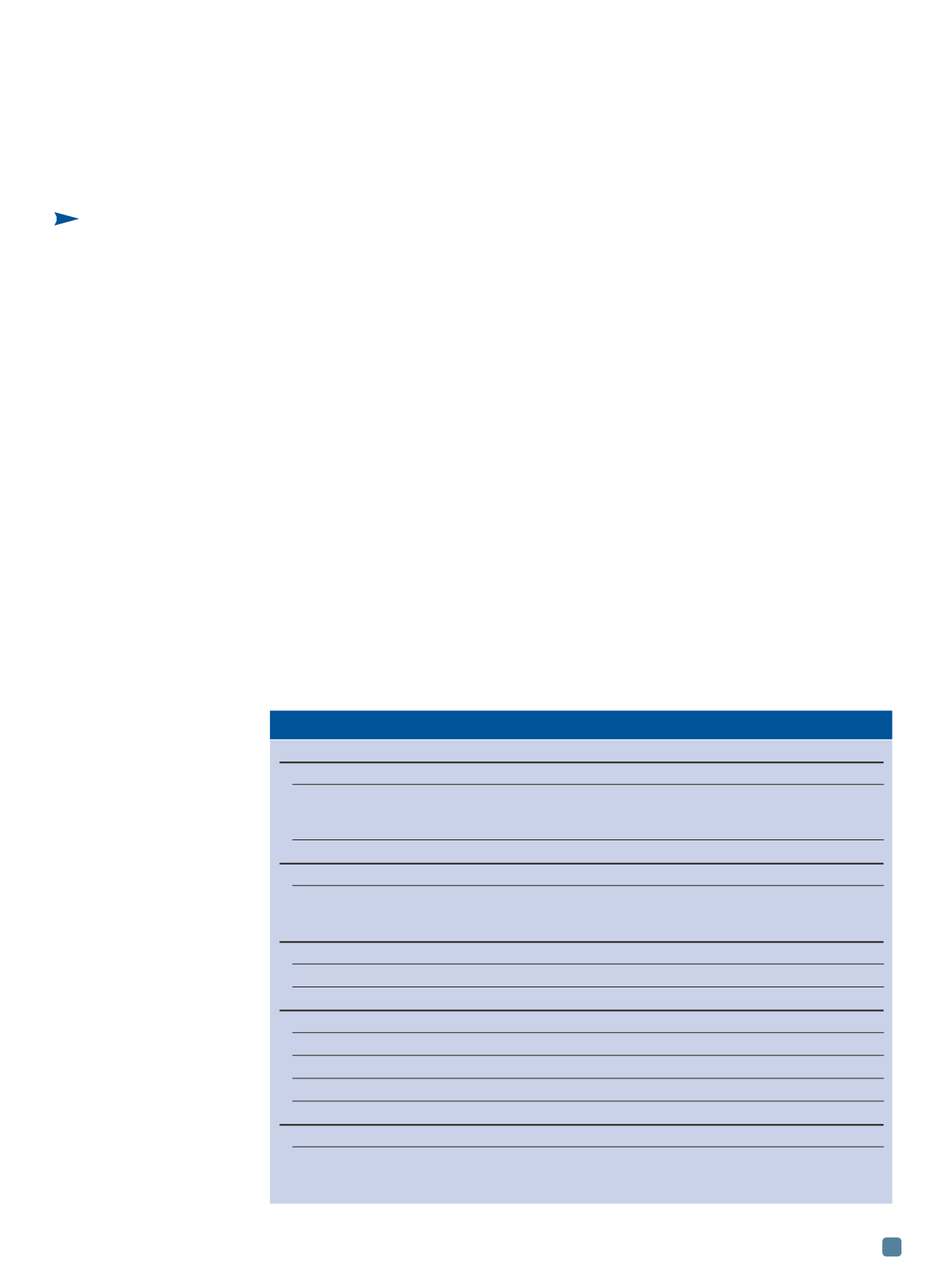

Inclusions in Mg alloys

Typical inclusions found in Mg alloys can

be categorized into either nonmetallic (oxides,

carbides, nitrides, chlorides, and salts) or inter-

metallic (iron-based) types. A summary of typ-

ical inclusions is shown in Table 1.

Each stage of the casting process is a poten-

tial source of inclusions in Mg alloys. Melting,

melt holding/transfer, and casting each exhibit

conditions in which the molten Mg surface may

be exposed to the atmosphere where inclusions

could form:

Melting —

Molten Mg reacts with oxygen to

formMgOwhen the melt is exposed to oxygen in

the atmosphere

[7, 8]

. In addition, all tools must be

dry or preheated before immersion to remove

moisture and to prevent MgO and hydrogen for-

mation (potential fire or explosion source).

Melt holding/transfer —

Actions such as

stirring, charging, ladling, poor venting, re-

moval of dross and sludge, and excessive move-

Abdallah Elsayed*

Sophie Lun Sin

Comondore (Ravi)

Ravindran, FASM*

Centre for

Near-net-shape

Processing of

Materials,

Ryerson University

Toronto

Understanding

both the origin

and procedures

for removing

inclusions in

magnesium

alloys results

in castings

with enhanced

mechanical

and corrosion

properties.

*Member of

ASM International

TABLE 1 — INCLUSIONS IN Mg ALLOYS

[4-6]

Type

Morphology Dimensions (

m

m) Density (g/cm

3

)

Oxides

MgO

Particles, films

10-300

3.58

0.5-1 (thickness)

50-400 (length)

MgO-Al

2

O

3

(spinel)

Particles

3.58

Nitrides

Mg

3

N

2

Particles, films

10-300

2.71

0.5-1 (thickness)

50-400 (length)

Carbides

Al

4

C

3

Particles

0.1-10

2.36

CaC

2

Particles

2-20

2.22

Chlorides and salts

MgCl

2

Particles

10-50

2.32

NaCl

Particles

10-50

2.17

CaCl

2

Particles

10-50

2.15

KCl

Particles

10-50

1.98

Iron-rich intermetallic compounds

Al

8

(Mn,Fe)

5

,

a

-AlMnFe,

Particles,

<20

4-7

(Mn,Fe)

5

Si

3

, Al

8

(Mn,Fe)

4

RE,

a

-Fe,

needles

Fe

2

(Si,B), Fe

3

(Al,Si), (Fe, Mn)

3

Si