ADVANCED MATERIALS & PROCESSES •

MARCH 2014

11

S

URFACE

E

NGINEERING

news

industry

briefs

Axalta Coating Systems,

Philadelphia, announced the

publication of its annual

automotive color popularity report

for 2013. This year’s report

includes

Say it with Color!,

Axalta’s

forecast of four color megatrends

for automotive designers around

the world. White strengthened its

position as the most popular

automotive color among

consumers worldwide in 2013,

growing in popularity by 6% over

the prior year. Black was the

second most popular color

globally, with 20% of sales, but

“effect black” was preferred more

than “solid black.” Silver at 15%

and gray at 12% waned in

popularity, while red held

steady at 8%.

www.axaltacoatingsystems.com.

The aerospace coatings group of

PPG Industries,

Sylmar, Calif.,

qualified Aerocron electrocoat

primer to SAE International’s

Aerospace Material Specification

3144 for anodic electrode position

primer for aircraft applications.

This qualification provides

airframe manufacturers and

subcontractors with third-party

verification of its performance

characteristics and attributes,

according to company

representatives. Four variations of

the PPG chromate-free primer

were qualified to AMS 3144 in

order to meet specific customer or

regional requirements.

www.ppg.com.

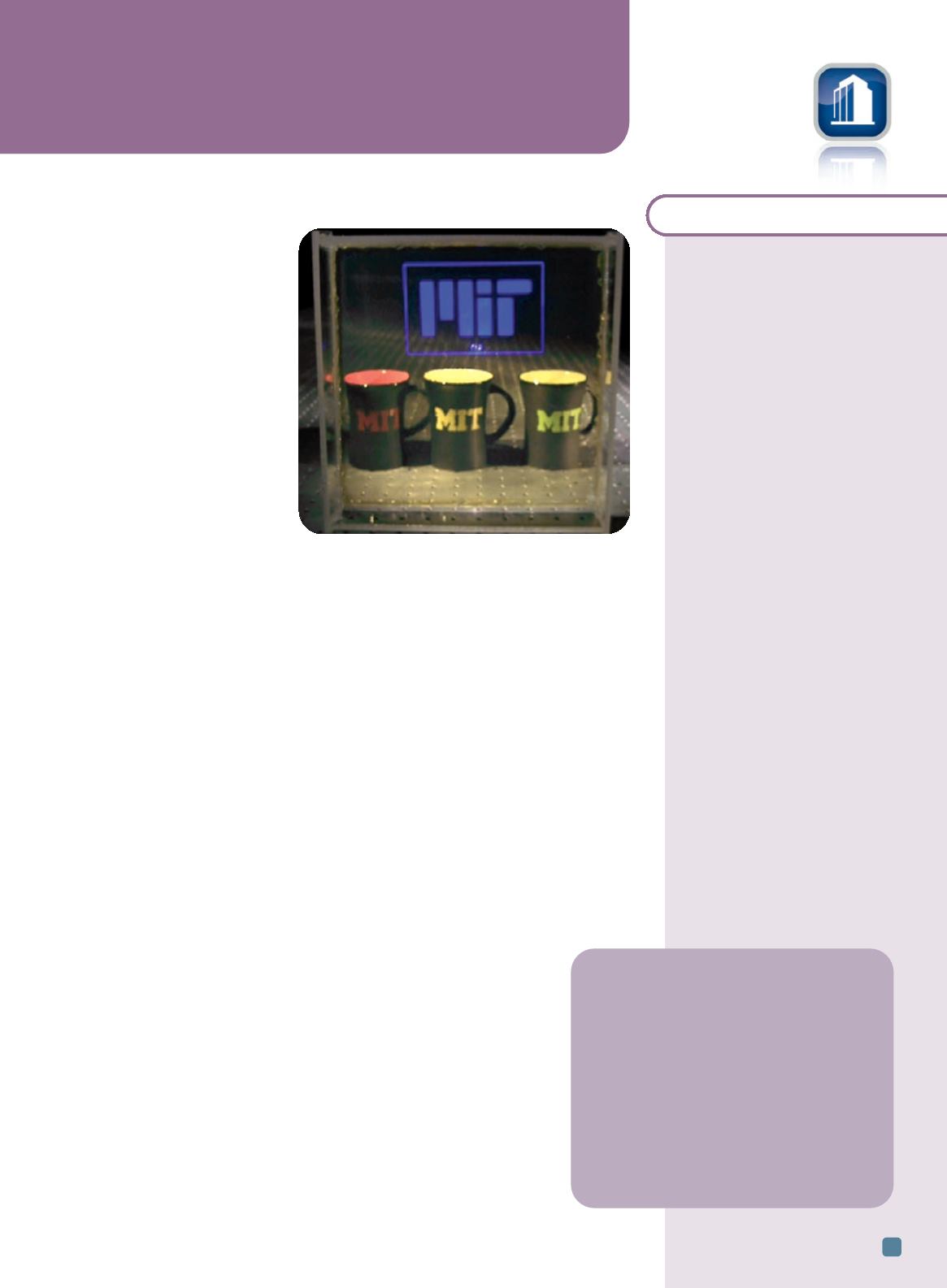

See-through screen could be applied on ordinary glass

Researchers at Massachu-

setts Institute of Technology,

Cambridge, came up with a new

approach for transparent dis-

plays that offers significant ad-

vantages over existing systems.

Nanoparticles are embedded

into the transparent material.

They can be tuned to scatter

only certain wavelengths, col-

ors, or light, while letting the

rest pass through.

To demonstrate the system,

a blue image was projected in

front of a scene containing cups

of several colors, all of which can

clearly be seen through the pro-

jected image. While the demonstration used silver nanoparticles, roughly 60 nm

across, which produce a blue image, researchers say it should be possible to create

full-color display images using the same technique. Three colors (red, green, and blue)

are enough to produce what we perceive as full-color, and each of the three colors

would still show only a very narrow spectral band, allowing all other hues to pass

through freely.

For more information: Marin Soljačić, 617/253-2467,

soljacic@mit.edu,

www.web.mit.edu/physics/index.html.Fast ASTM test standard for transportation coatings

A collaborative 14-year effort involving BASF, Germany, automotive and aerospace

OEMs, material suppliers, and test equipment manufacturers resulted in a new ASTM

test standard for transportation coatings. The new method is 30-40% faster than the

previous test standard, and improves the accuracy to nearly 100% in predicting coat-

ing service life compared to less than 50% before. Officially named ASTM D7869-13

Standard Practice for Xenon Arc Exposure Test with Enhanced Light and Water Expo-

sure for Transportation Coatings, the new test simulates physical and environmental

stresses that an exterior transportation coating is exposed to in a subtropical climate.

These stresses include long water exposures, wet/dry cycling, and high dosages of solar

radiation, all of which have been shown to cause severe coating deterioration.

www.basf.com.

Flying with environmentally-friendly coatings

The European Union ECOPROT project aims to industrialize an innova-

tive procedure for producing corrosion-protecting, environmentally friendly

coatings for aluminum and magnesium alloys, to be used in the aeronautics

market. Unlike other commercial solutions trying to penetrate the market,

this coating reportedly provides a corrosion performance comparable to that

of the toxic chromates, meeting the rigorous standards of the aeronautics in-

dustry. The slightly higher price of the product compared to current coatings

is offset by its greener environmental impact, say researchers.

The new process was granted a patent and developed through an FP6 proj-

ect called Multiprotect. While the coating has huge potential in the aeronau-

tic market, scaling up production and achieving market penetration has been

difficult. The aim of ECOPROT is to industrialize the procedure and raise in-

dustry awareness of this glasslike, environmentally friendly, and self-healing

cerium-based coating.

www.ecoprot.eu.

Carboline Co.,

University Heights, Ohio, released Car-

botherm 551, an advanced insulative coating. The

water-based epoxy coating has multiple uses, from pro-

tecting workers from burns on hot surfaces to thermal

insulation. It dramatically reduces the effects of solar

radiation on operating vessels and storage tanks and

reduces heat buildup, which can otherwise result in

evaporative emissions from storage tanks containing

hydrocarbon or other cargo. The coating can provide up

to 60% energy efficiency when applied at only 4-6 mm.

In a single coat, it can protect against heat caused by

solar radiation for pressure vessels, hydrocarbon stor-

age tanks, liquefied petroleum tanks, and other contain-

ers.

www.carboline.com.