Improving superalloy performance

Work from Helmholtz-Zentrum Berlin für Ma-

terialien and Energie (HZB), and University of Mün-

ster, both in Germany, shows how new phases in a

nickel-base alloy form and evolve, offering clues to

how high-performance alloys could be improved.

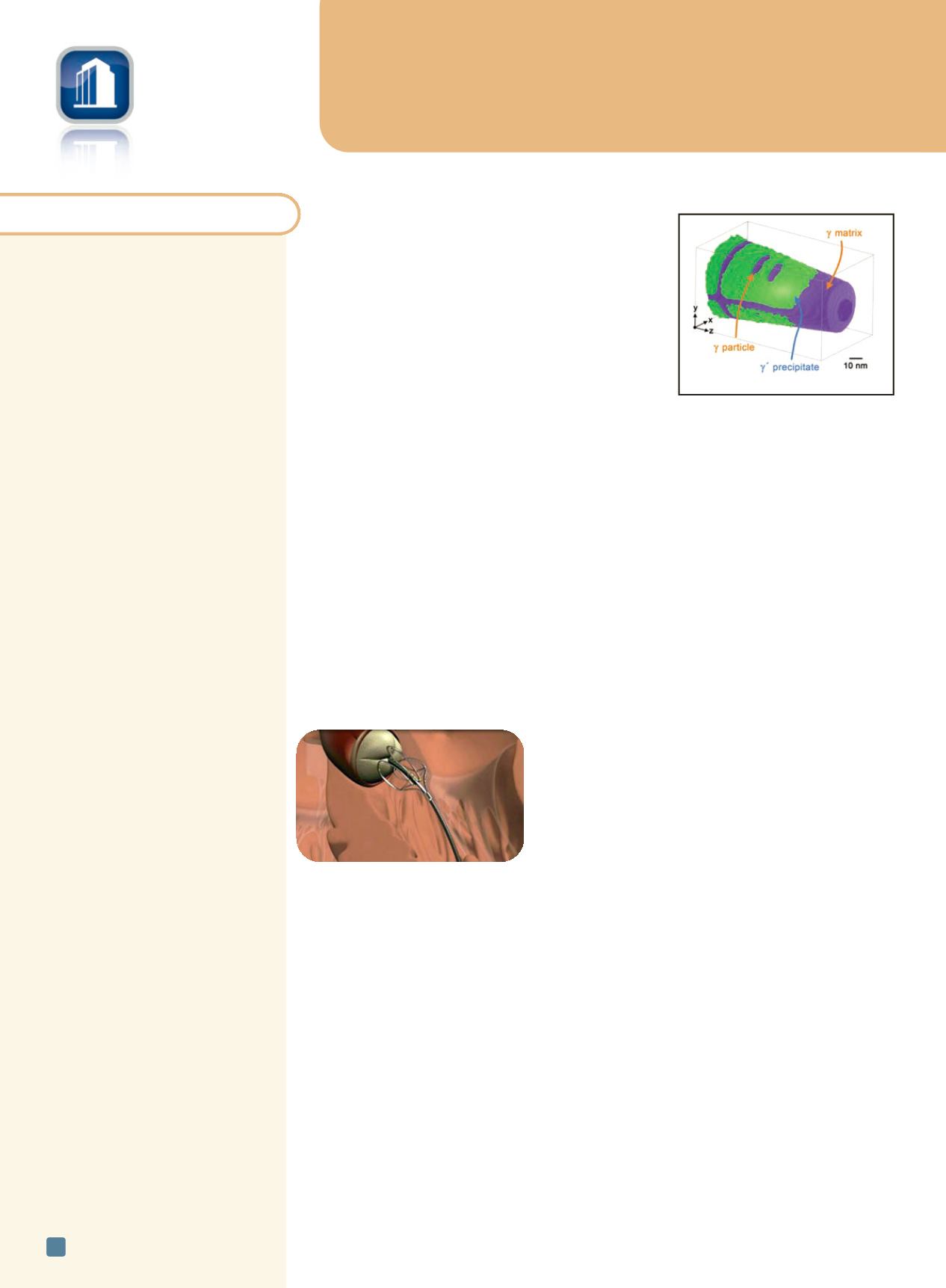

Researchers combined transmission electron mi-

croscopy (TEM) and atom probe tomography (APT)

to accomplish this. The microstructure of nickel-

base alloys changes under controlled aging or heat

treatment and in the classical two-phase microstruc-

ture new phases are initially formed. Researchers

precisely observed the phase separation process on

the atomic scale for the first time.

To do so, they simulated the aging process of the

alloy by heat treating it for different periods. They

documented how the microstructure changed dur-

ing aging by using micrographs from the TEM.

Whereas the classical two-phase microstructure

consists of cuboid γ’ precipitates embedded in a so

called γ-matrix, during heat treatment, spherical γ particles initially form in the γ’ precip-

itates of the alloy, and then further coalesce into plates that finally split the γ’ precipitates.

The thermo-mechanical properties of these types of alloys depend largely on the stability

of this γ/γ’ microstructure.

www.helmholtz-berlin.de/index_en.html.FDA approval for guidewire

MediValve Ltd., Israel, received 510(k) pre-marketing clearance from the U.S. Food

and Drug Administration for its acWire guidewire, intended for use in peripheral vascu-

lar and heart catheterization procedures, to introduce

and assist in positioning diagnostic and interventional

devices. The guidewire may also function as an align-

ment tool by providing a reference plane of the

anatomical structure of interest. It is a single-use, fully

disposable medical device that uses shape-memory

alloy technology to enable identification of cardiovas-

cular structures using existing imaging methods. The

device is intended for implantation plane acquisition,

during trans-catheter aortic-valve implantation

(TAVI) procedures using fluoroscopic imaging.

www.medivalve.com.

Plastics machinery safety standards update

The Plastics Industry Trade Association, Washington, and the American National

Standards Institute (ANSI) announce the publication of two recently revised and ap-

proved American National Standards on plastics machinery safety: ANSI/SPI B151.20 -

2013 Safety Requirements for Plastics Sheet Production Machinery, and ANSI/SPI

B151.27 - 2013 Safety Requirements for the Integration of Robots with Injection Mold-

ing Machines, both of which address detailed safety requirements for the specific ma-

chine or group of machines.

B151.20 specifies requirements for the manufacture, care, and use of plastics sheet pro-

duction machinery to minimize hazards to personnel associated with machine activity.

B151.27 addresses the integration, care, and use of robots used with injection molding ma-

chines to minimize hazards to personnel associated with robot and machine activity.

www.plasticsindustry.org,

www.ansi.org.

news

industry

briefs

Duke University’s Pratt School of

Engineering,

Durham, N.C.,

researchers used computational

methods to identify dozens of

platinum-group alloys with

databases and algorithms that took

years to develop. Using theories

about how atoms interact to model

chemical structures from the

ground up, thousands of potential

materials were screened for high

probabilities of stability. After

nearly 40,000 calculations, results

identified 37 new binary alloys in

the platinum-group metals, which

include osmium, iridium,

ruthenium, rhodium, platinum, and

palladium. These metals are prized

for their catalytic properties,

resistance to chemical corrosion,

and performance in high-

temperature environments.

www.pratt.duke.edu.

Porous Power Technologies LLC

(PPT),

Boulder, launched

Symmetrix NC2020, a ceramic

battery separator designed to

improve thermal stability and

safety of large-format lithium-ion

batteries. The separator is

nonflammable and more resistant

to shrinkage than conventional

separators, making cells more

stable when damaged or abused.

The ceramic particles are blended

with PVDF polymer to form a

flexible, ceramic-rich microporous

membrane. Ions flow freely

through the open pore structure,

enabling cells with good power

over broad temperature ranges.

The sponge-like membrane

conforms to the electrode surface

to prevent dead spots and ensure

reliable performance, even as

electrodes expand and contract

over many cycles.

M

ETALS

P

OLYMERS

C

ERAMICS

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

6

3D reconstruction of an atom probe

measurement. The

g

matrix (purple)

is surrounding the cuboidal

g

’

precipitates (green). Only a few

nanometer-sized

g

platelets are seen

in the

g

’

precipitates. APT allows

site-specific analysis of the structure

at the atomic scale and reveals the

chemical composition in

measurements of individual areas.

Courtesy of HZB.

MediValve receives FDA 510(k)

approval for acWire guidewire.

Courtesy of MediValve Ltd.