iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

4 2

iTSSe

TSS

FEATURE ARTICLE

10

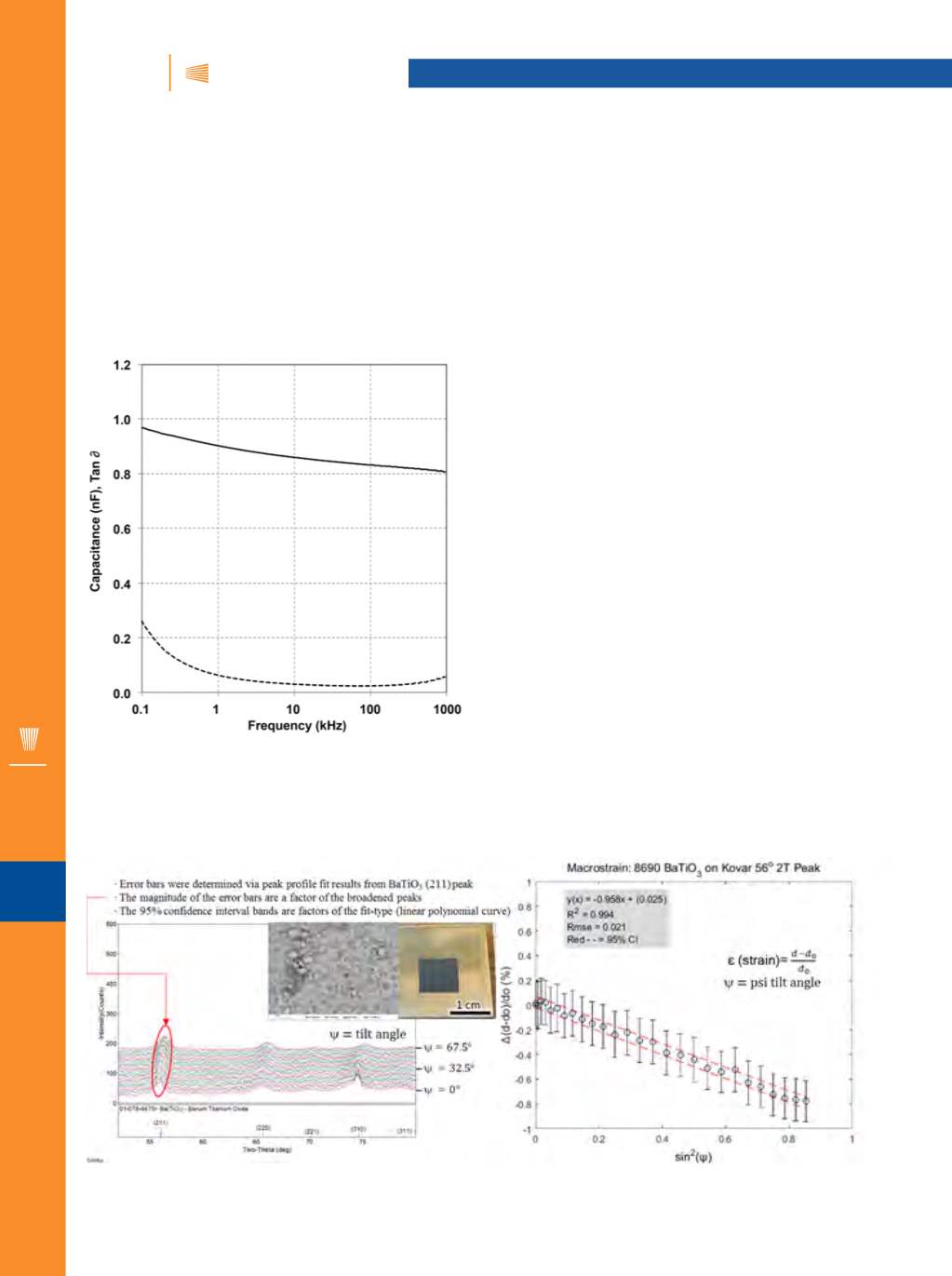

Fig. 3 —

Frequency dependent capacitance and dielectric loss

(tan ∂) of 4 mm

2

capacitors defined on as sprayed 5-7 µm thick films

on Kovar. Low frequency dielectric loss is a common attribute of

as-sprayed BaTiO

3

that exhibits significant space charge contribu-

tion to total polarization.

Fig. 4 —

XRDmeasurement and strain calculation on the 4 µm thick BaTiO

3

film on Kovar substrate. The strain was on the order of ~1%, corre-

sponding to ~1 GPa residual compressive in-plane stress.

low melting point substrates such as glass, metal, or plastic.

Moreover, BaTiO

3

is susceptible to point defect formation by

highly reducing thermal processes. Thermal spray lends itself

to electron-rich point defect formation due to volatilization

of typical A-site substitution cations, including bismuth or

lead. In addition, oxygen vacancy formation that contributes

to sub-band electrical transport is enhanced by the thermal

processing and rapid quenching used in thermal spray pro-

cesses. The associated dielectric properties, such as insulation

resistance, dielectric constant, and dielectric loss are therefore

significantly impacted by melting/solidification in traditional

plasma spray.

The AD process was used to successfully integrate high

density thick BaTiO

3

films with copper (Tm = 1085°C) at room

temperature. The aerosol deposited BaTiO

3

film crystal struc-

ture, grain size, residual strain, and dielectric properties are

currently being investigated. Preliminary results show that

5-7 µm thick BaTiO

3

films produce 1 nF capacitors with a 2 x

2 mm (providing a 4 mm

2

area) gold electrode. A 3 x 3 matrix

of electrodes was defined on the 1-cm deposition area. Each

electrode spans a 4 mm

2

area. Seven of the nine 4 mm

2

elec-

trodes demonstrate potential as capacitors with loss values in-

dicative of continuous, non-cracked films. Figure 3 shows the

frequency dependent capacitance and dielectric loss from100

Hz to 1 MHz. As-aerosol-deposited films exhibit some space

charge contribution to polarization. The permittivity of the

films was calculated to be k~200, which is consistent with oth-

er published research.

Although polycrystalline BaTiO

3

capacitors generally

exhibit k>1000 at room temperature, these films exhibit sig-

nificant crystalline disorder and amorphous grain boundary

volume. This combination of grain boundary volume and

crystalline disorder reduces polarization by hindering Ti4+

mobility within the unit cell and reduces domain wall motion

by defect pinning. In addition, these films exhibit significant

in-plane crystallographic strain quantified by XRD analysis.

The in-plane strain is approximately 1%as determined by XRD

analysis (Fig. 4), which corresponds to an approximate com-

pressive stress of 1 GPa.

The as-deposited coatings also have very small grain

size (20-75 nm or less). Small grain size may be beneficial for

structural ceramics, but larger grain size on the order of