iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

4 4

iTSSe

TSS

CASE STUDY

12

REASON TO CONSIDER RESURFACING

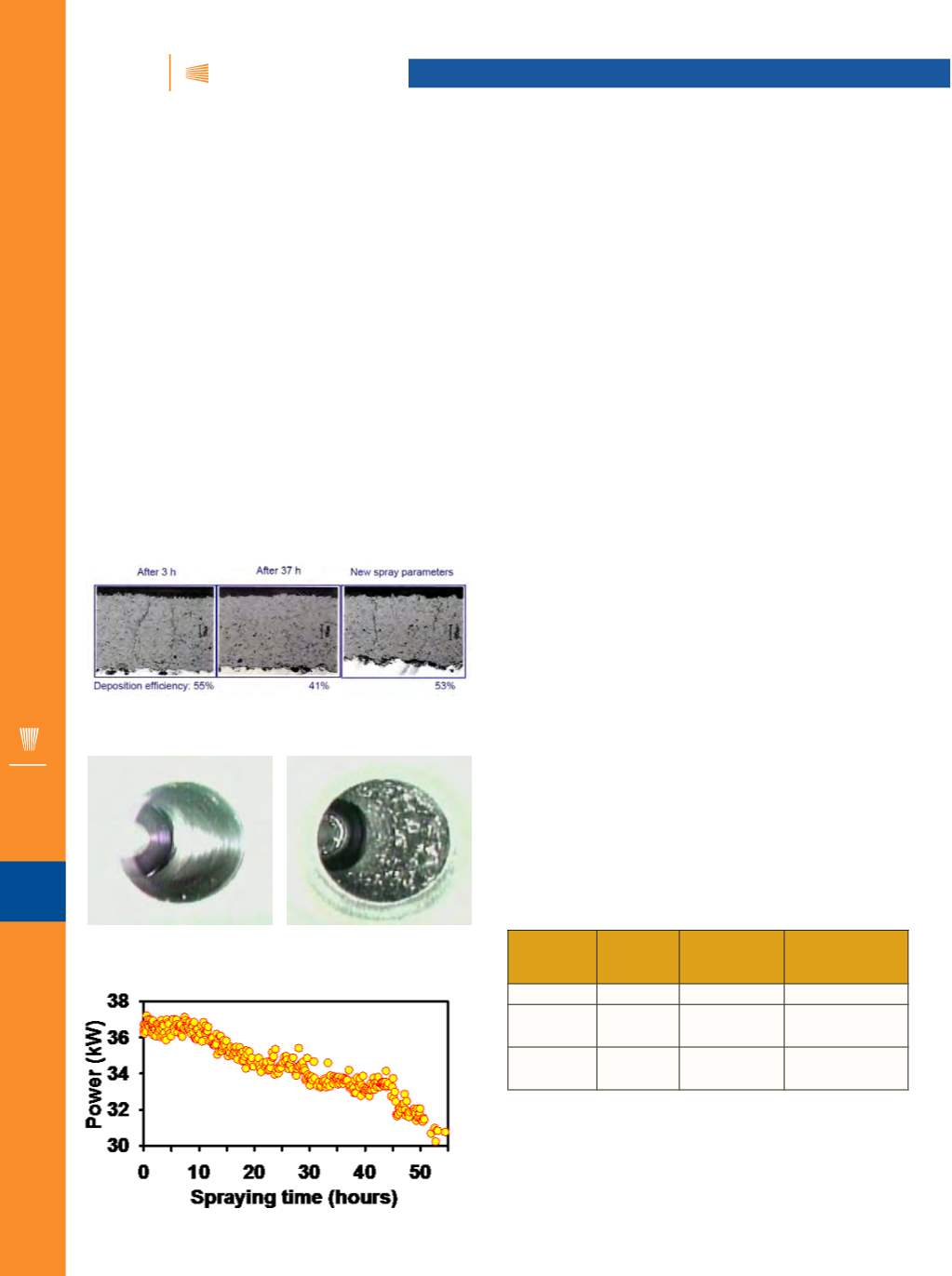

Keeping a particle’s characteristics constant over time

yields coatings with very similar properties. An experiment

was conducted where 8%-YSZ is sprayed for 37 hours starting

with a brand new set of electrons. The torch is stopped and re-

started every hour. Visual inspection of the inside of the nozzle

is carried out every hour and gun power is measured. Finally,

particle characteristics are monitored using an online spray

diagnostic tool from Tecnar, Canada. After 37 hours, the elec-

trodes are worn, gun power has decreased, and the initial mi-

crostructure of the coating (TBC) has disappeared. However,

after the 37 hours, spray parameters were modified to retrieve

the initial particle properties as well as corresponding coating

characteristics such as porosity, vertical crack network, and

deposition efficiency (DE).

VALUE OF INSPECTION

Nearly three decades ago, thermal spray researchers

recognized the need for advanced diagnostic tools able to pro-

vide spray material characteristics just before impingement

on the part, independently of upstream parameter controls.

This need was focused mostly around fundamental under-

standing of the spray process, validation of thermo- and flu-

id-dynamic models, development of advanced materials, and

development and optimization of spray equipment. Produc-

tion managers, on the other hand, had different objectives

in mind—namely improving coating reproducibility (P

pks

and

C

pks

), extending electrode lifetime, reducing test coupons, im-

proving DE, better forecasting of coating thickness, and spray-

ing correctly the first time.

OPTION

It is well known that lot-to-lot variations exist for com-

mercially available powders, and that powders supposed to

be a direct replacement sometimes yield very different coat-

ings. Below is an example where the same powder (reference)

has been used for more than a decade. For various reasons,

an alternate supplier is sought. Two other suppliers propose a

direct replacement to the reference powder. The three mate-

rials are sprayed the same morning, with the same torch and

hopper, in the same spray booth, and by the same operator.

Coupons are produced and, for each spray run, particle char-

acteristics aremeasured using an online spray diagnostic tool.

BENEFITS

Results clearly show that Alternate-1 succeeded in pro-

viding a direct replacement powder, which was confirmed by

the coating microstructure. Alternate-2 provided a material

significantly different from the sensor standpoint, which was

also confirmed by coating microstructure.

~iTSSe

Powder

Average

velocity

(m/s)

Average

temperature

(°C)

Microstructure

Original

613

1549

Reference

Alternate-1

616

1535

Same as

reference

Alternate-2

652

1819

Different (denser

coating)

Formore information:

Luc Pouliot is executive vice president,

Tecnar, 1321 Hocquart St., Saint-Bruno-de-Montarville, QC,

Canada, J3V 6B5, 450.461.1221 ext. 235,

lpouliot@tecnar.com,

www.tecnar.com.

Images courtesy of Christian Moreau/National Research

Council of Canada.

ONLINE DIAGNOSTIC TOOLS IMPROVE

THERMAL SPRAY PROCESS

Fig. 1 —

Effect of electrode wear on coating characteristics.

Fig. 2a —

New electrode.

Fig. 2b —

Worn electrode.

Fig. 3 —

Evolution of plasma power over time.