iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 6

4 7

JTST

HIGHLIGHTS

15

iTSSe

TSS

CORRELATION OF IMPACT CONDITIONS,

INTERFACE REACTIONS, MICROSTRUCTURAL

EVOLUTION, AND MECHANICAL PROPERTIES

IN KINETIC SPRAYING OF METALS: A REVIEW

Jaeick Kim and Changhee Lee

Most studies into kinetic spray technology focus on basic

research, but a large portion of current research is devoted to

industrial applications of the technology. However, to advance

studies on industrial applications of kinetic spray requires a

profound understanding of the scientific foundations of the

process. Nevertheless, there is not yet a well-organized sum-

mary of the correlations among impact conditions, interface

reactions, microstructural evolution, and mechanical prop-

erties across the whole field of kinetic spray technology. This

paper provides an overview of these correlations for kinetic

spray of metals. For each correlation, interactions between the

given conditions and material properties of the metal feed-

stock powder are the most influential. These interactions are

so complicated that it is difficult to systematically classify all

cases into certain types. An attempt is made to explain and

summarize the critical factors and their roles in each relation-

ship (Fig. 5).

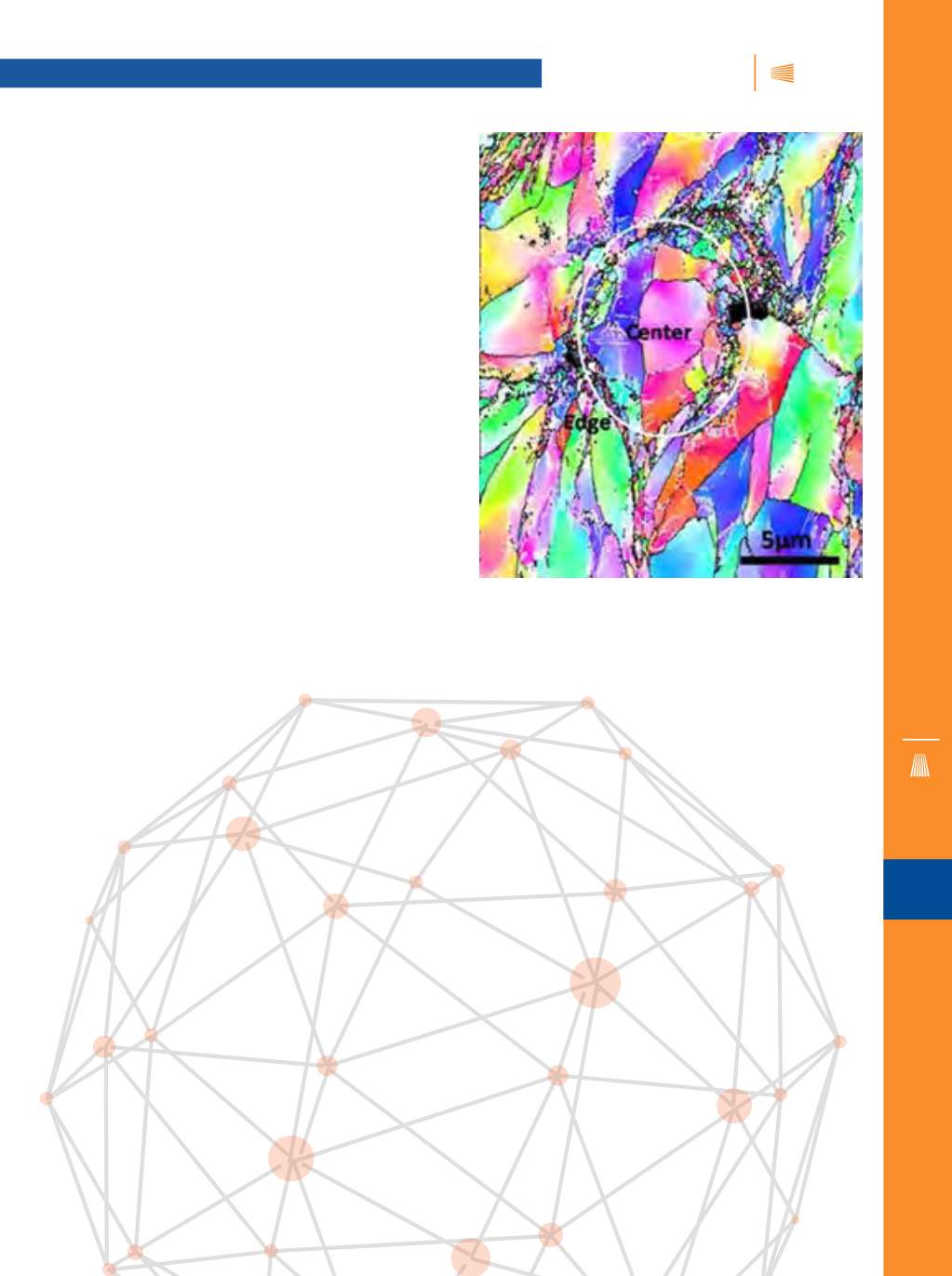

Fig. 5 —

EBSD characterization of Ni coating after nanoindentation:

Euler angle map.