iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

4 6

iTSSe

TSS

JTST

HIGHLIGHTS

14

alloy coatings tested in previous research. On the other hand,

corrosion resistance of the coating material (tested by electro-

chemical polarization in 0.1 M HCl solution) is quite low. Even

in the absence of interconnected porosity, this results in ex-

tensive, selective damage to the Fe-base matrix. This coating

material is therefore unadvisable for highly corrosive environ-

ments (Fig. 2).

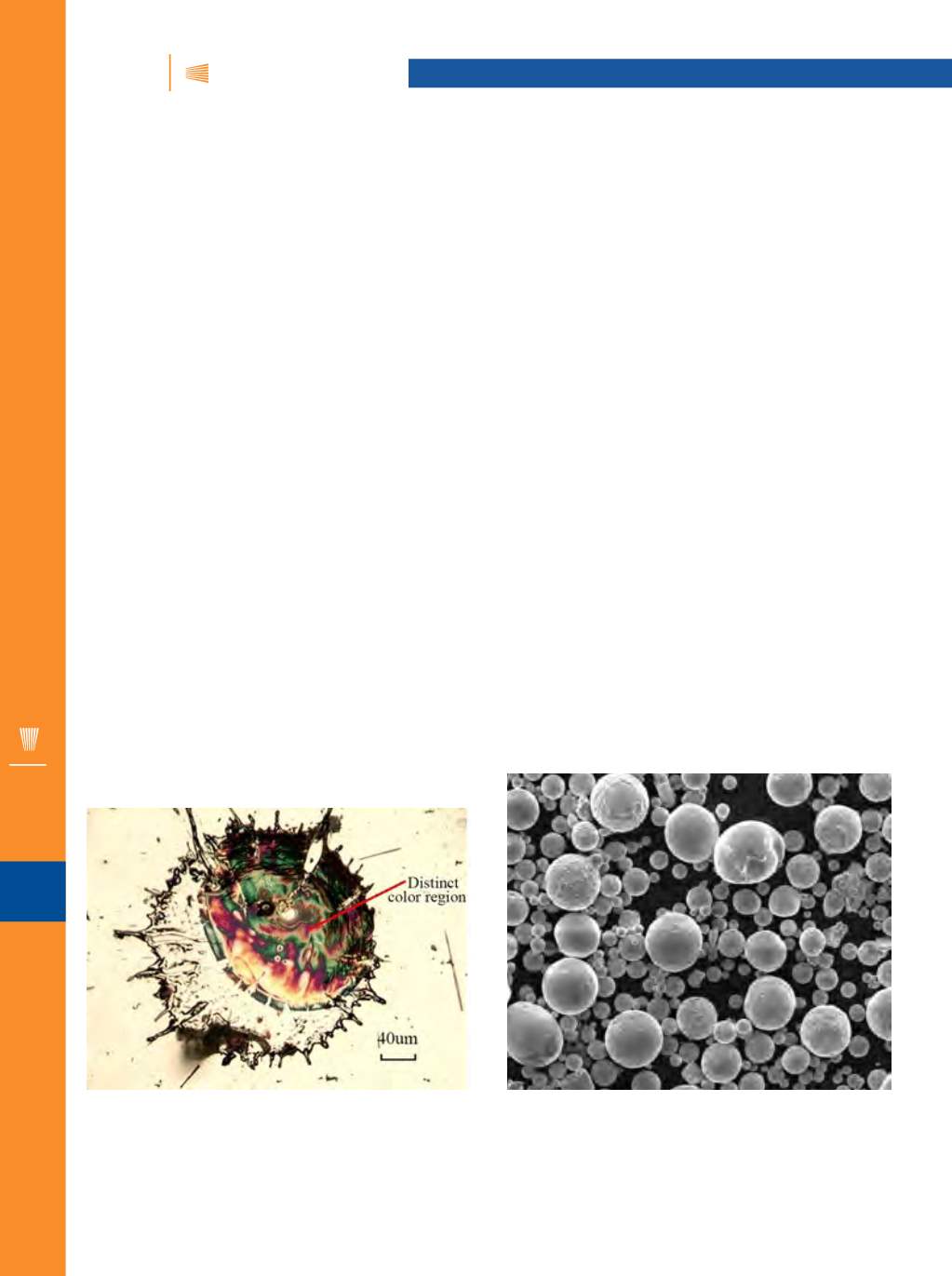

EFFECT OF SOLID SHIELD ON COATING

PROPERTIES IN ATMOSPHERIC

PLASMA SPRAY PROCESS

Ting Liu, Lili Zheng, and Hui Zhang

This paper investigates the impact of shrouded shield

structure on plasma spray processes and optimal shield

structure selection. Plasma flame characteristics’ response to

solid shield structures is studied first, and experimental inves-

tigations are then performed for both atmospheric (APS) and

shrouded (SPS) plasma spray processes. Useof a conical shield

with a divergence angle of 5.5° and 90-mm length is effective

to form a low-oxygen (<2%) and high-temperature (>3000 K)

region in the plasma flame, which covers the main area where

particles pass by. The average particle temperature is higher

in SPS than APS with the given conditions, and such behavior

is intensified as solid shield length increases. Using SPS, more

disk-shaped splats are obtained and the oxygen concentration

in the coating is significantly reduced. The degree of oxidation

in the coatings is further reduced as the length of the solid

shield increases from 50 to 90 mm. Applying the solid shield

leads to high flame temperature and low oxidation; howev-

er, substrate overheating and velocity reduction may occur.

For the cases studied, optimal shield length is around 90 mm

(Fig. 3).

COLONIZATION OF BACTERIA ON

THE SURFACES OF COLD SPRAYED

COPPER COATING ALTERS THEIR

ELECTROCHEMICAL BEHAVIORS

Xinkun Suo, Peng Xia, Yi Liu, Leila Abdoli, Xiaotao Luo,

Guanjun Yang, and Hua Li

Copper coatings were fabricated on stainless steel plates

by cold spray. Attachment and colonization of

Bacillus sp.

on

the surfaces of cold spray copper coatings in artificial seawa-

ter were characterized and their effects on anti-corrosion per-

formance of coatings were examined. Attached bacteria were

fixed and observed using field emission scanning electron

microscopy (FESEM). Electrochemical behaviors including

potentiodynamic polarization and electrochemical imped-

ance spectroscopy with and without bacterial attachment

were evaluated using the commercial electrochemical analy-

sis station, Modulab. Results show that

Bacillus sp.

prefers to

settle on low-lying spots of coating surfaces in an early stage,

followed by recruitment and attachment of extracellular poly-

mers (EPS) secreted through metabolism of

Bacillus sp.

The

bacteria survives on coating surfaces with the protection of

EPS. The attachment model is proposed to illustrate bacteria

behaviors on the surface of copper coatings. Electrochemical

data shows that current density within the

Bacillus sp.

envi-

ronment decreases compared to that without. Charge-trans-

fer resistance increases markedly in bacteria-containing ASW,

suggesting that corrosion resistance increases and corrosion

rate decreases. The influence mechanism of bacteria settle-

ment on corrosion resistance of cold spray copper coatings is

discussed (Fig. 4).

Fig. 3 —

Optical micrograph of splat morphology: APS process.

Fig. 4 —

Surface morphology of copper powder.